Plastic Corrugated Sheet made of virgin material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

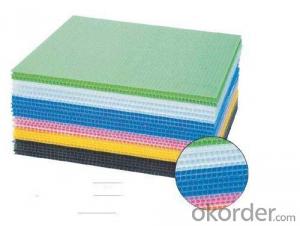

CMAX PP Plastic Hollow Sheet is an extruded twin wall plastic sheet consisting of two flat walls connected by vertical ribs. Eco-friendly PP Plastic Hollow Sheet is mainly manufactured from a high impact co-polymer polypropylene (PP) or polyethylene (PE) resin, which can be recycling, washable, durable and re-useable etc. CMAX Polypropylene PP Twin Wall Corrugated Plastic Hollow Sheets / Board / Signs has proved that it is suitable in the uses of packaging, advertising, construction, agriculture, industry and Pharmaceutical etc.

Specification:

1. Thickness: 2mm,3mm,4mm,5mm,6mm,7mm,8mm,10mm,12mm

2. Weight: From 250g/m2 to 3500g/m2

3. Standard Size: 2440mmx1220mm, 2000x1000mm, 1200x800mm, 1000x1000mm or as request

4. Grade:Corona Treated, Anti-Static, Conductive, UV Stabilized and Flame Retarded etc;

Feature:

CMAX Polypropylene PP Corrugated Plastic Hollow Sheet offers efficient solutions to a wide variety of applications. Compared to alternatives such as cardboard, metal or rigid plastic, Eco-friendly Twin Wall Corrugated Plastic Polypropylene PP Hollow Sheet offers the following unique advantages

1. Economical : both in use and purchase

2. Flexible : as a material and as application

3. Environmentally sound : recyclable

4. Water and moisture resistant

5. Approved for food packaging

6. Strong and durable

7. Lightweight

8. Good chemical resistance

9. Easy to print

Description | PP hollow sheet/PP corrugated sheet is a kind of environmental material, which is pollution-free and recyclable, made of polypropylene (PP) and polyethylene (PE) | |||||||||

Width | ≤2100mm | |||||||||

Length | As required. | |||||||||

Thickness | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 9mm | 10mm | 11mm | 12mm |

GSM | 250-500 | 300-600 | 600-900 | 800-1200 | 900-1600 | 1400-2000 | 1600-2000 | 1600-2200 | 2200-2400 | 2400-2600 |

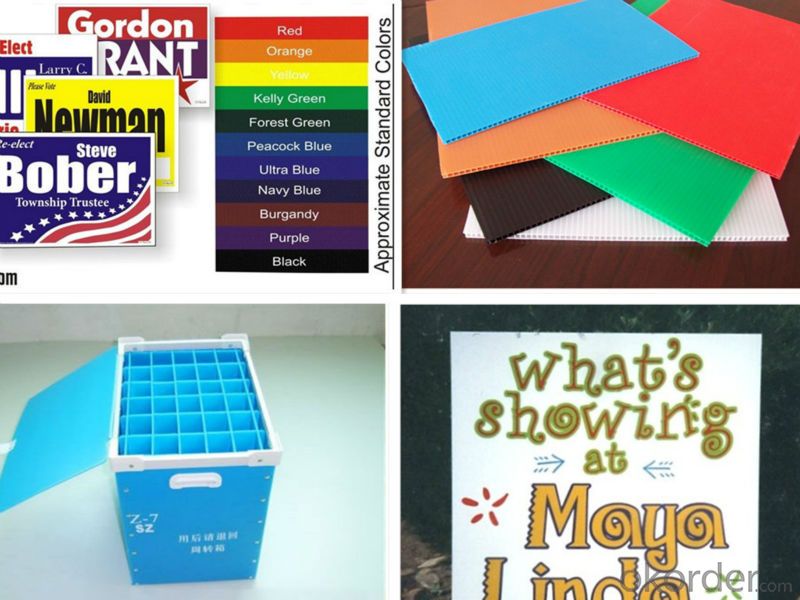

Application | Packing | Transfer Box,mail box,display rack,partition,gift box,food packing,turnover box,dustbin,etc. | ||||||||

Advertising | Sign board,exhibition board,billboard,caution board,picture frame backing,digital printing and screen printing. | |||||||||

Decoration | Partitions,wall cladding,indoor and outdoor decoration,windows and false ceilings,floor cover,greenhouse roof. | |||||||||

Stationery and art design | It has multi-color,suitable for art design & various pattern box or delicate gift pack. | |||||||||

Feature | Light weight,rigid,strong and long time durable. | Waterproof,moisture resistance,excellent weather ability. | ||||||||

Chemical resistance,anti-impact,fade resistance. | Environmental friendly,recyclable,washable,non-toxic. | |||||||||

Easy to fabricate,custom-made cut shape. | Excellent surface for paints and inks easily,anti-corrosion. | |||||||||

Grade | Common,Corona Treated,Anti-Static,Conductive,UV Stabilized,etc. | |||||||||

Color | Clear,Black,White,Blue,Red,Yellow,Green,Pink,Or as required. | |||||||||

Advantage | Capacity:600MT per month; Prompt delivery; Factory Direct Selling; ISO-9001 | |||||||||

FAQ:

1. Where is you factory located?

Our factory is located near Shanghai. Your order will be delivered to Shanghai port quickly.

2. What kinds of materials do you use?

Normally, we use both virgin and recycled materials for production

3. How can you guarantee the quality?

We have more than 20 employees who are engaged in quality inspection, we promise every sheet comes out of our factory is guaranteed.

- Q: They need to be non-adhesive.

- Spray it with acrylic wax

- Q: Plastic gusset plate how to see good or bad?

- According to industry standards to buy, the standard provides that the wall thickness of not less than 0.7 mm, especially decorative surface, manufacturers of products must meet this requirement. When buying, users only need to measure the profile wall thickness.

- Q: I want to build a faster oven for drying plastic sheets. I currently us an 8'x8' low temp gas oven but need to dry more material faster. I've seen info on a woodworker that built a Microwave dryer for large wood projects and wonder if the same technology can be used to dry plastic. A major concern of course is containing the microwave radiation. I'm open to any safe ideas.

- It can be done, and done safely, although microwaves might not be the best source of energy for that particular application. Radio frequency energy might be a better choice. Unfortunately, this forum isn't really the best place for a detailed discussion. Click the source link below and feel free to make contact.

- Q: We bought flannel sheets and are left with these lovely plastic packaging with the zipper on top. I would love some creative ideas to reuse them. Links would also be appreciated.

- I have used them to store my child's old baby blankets,pillows,clothes or even baby toys. They are a wonderful thing to use to store keepsake items.

- Q: Can plastic sheets be used for greenhouse construction?

- Yes, plastic sheets can be used for greenhouse construction. They are commonly used as greenhouse coverings due to their affordability, durability, and ability to allow sunlight to penetrate while retaining heat. Plastic sheets such as polyethylene or polycarbonate are often used to create a greenhouse structure, providing an ideal environment for plants to grow.

- Q: i'm in ireland and don't know where to buy it

- Any large DIY store, or farmers in your area may have spare from baling time. Thinking on it , won't you get it at Woodies?

- Q: my car windscreen sticker was full of permanent marker marks done by little kids. i need to lift the marks without spoiling the sticker.

- It can be done quite easily. Try a bit of rubbing alcohol or a paint mixer called thinner. Just wet a piece of cloth in thinner and gently rub off the marker marks. You can even try surgical spirit.

- Q: Are plastic sheets resistant to termites?

- Yes, plastic sheets are generally resistant to termites as they are made of synthetic materials that termites are unable to digest or destroy.

- Q: is 3.5 mil thick plastic sheeting thick enough to use for a backyard ice rink?

- That should be fine. It's not the plastic, its the temperature. If its cold enough, the water will freeze even if you just flood the grass, on a cheap tarp, etc.

- Q: Can plastic sheets be used for swimming pool covers?

- Yes, plastic sheets can be used as swimming pool covers. They are often lightweight, durable, and water-resistant, making them suitable for protecting the pool from debris and evaporation. However, it is important to choose a high-quality, UV-resistant plastic sheet to ensure longevity and prevent damage from sun exposure.

Send your message to us

Plastic Corrugated Sheet made of virgin material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords