PVC Foam Board and Sheet Raw Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 1000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

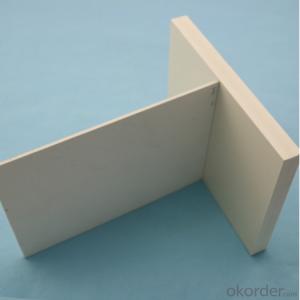

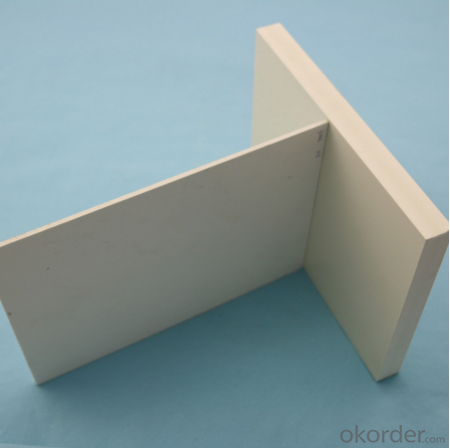

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

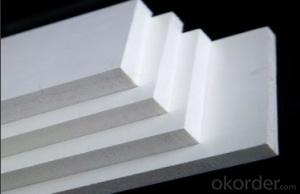

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm or as your request

Thickness:1-33mm

Density:0.35-0.9

Production Capacity:10000pcs per month

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

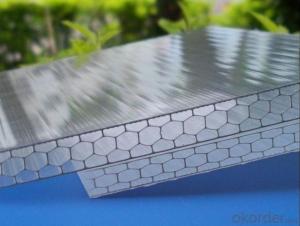

5.Product Pictures

- Q: Can plastic sheets be used for vacuum forming in the aerospace industry?

- Yes, plastic sheets can be used for vacuum forming in the aerospace industry. Vacuum forming is a widely used manufacturing process in aerospace for creating various components and parts. Plastic sheets, such as high-performance thermoplastics, are often used due to their lightweight, durable, and cost-effective nature. These plastic sheets are heated and then shaped over a mold using vacuum pressure, resulting in precise and complex aerospace components.

- Q: for our last day of term at uni, we are hoping to make a big water slide down our corridor, (about 12m x 2m) the sheet would have to be waterproof as it will be covered in either washing up liquid or baby oil (probably no actual water) at the minute our cheapest material is looking like bin bags and duct tape, but does anyone know of a cheap, plastic like material we could use instead, to avoid the inevitable leaks from the joins?

- Go to any builders yard and you can get a massive roll of 1000g plastic which is generally used as DPC (damp proof course) under the floors of buildings. Cost...long time since I bought it about ?30/ or you can buy any length of it you like, off the roll.

- Q: Can plastic sheets be thermoformed?

- Yes, plastic sheets can be thermoformed. Thermoforming is a manufacturing process where plastic sheets are heated and then molded into various shapes using a combination of vacuum pressure and/or mechanical force. This process is commonly used in industries such as packaging, automotive, and aerospace to create products like trays, containers, and interior panels.

- Q: A sheet of plastic, n = 1.5, 25 mm thick is used in a bank teller's window. A ray of light strikes the sheet at an angle of 45°. The ray leaves the sheet at 45° but at a different location. Use a ray diagram to find the distance between the ray that leaves and the one that would have left if the plastic were not there. mm

- I think you will need a calculation to find a solution to this problem: The incident ray if it were to travel through the plastic without being refracted would emerge 25mm from the normal Use Snell's law to find the angle of refraction with the plastic present sin i / sin r = 1.5 So sin r = sin i /1.5 sin r = 0.7071 / 1.5 = 0.4714 Hence r = 28 degrees (angle of refraction inside the plastic) If the ray emerges at distance x from the normal then x is found from the right angled triangle Tan 28 = x / 25 x = 25 x tan 28 = 25 x 0.5317 = 13.3 mm Difference is thus 25mm - 13.3mm = 11.7mm separation

- Q: I've been given the responsibility by a family member to take care of 500-600 full stamp sheets from the 60's 70's. They are currently stored kind of haphazardly in large envelopes that, surprisingly, has kept them in really nice condition. But at this time I'd like to take the time to store them properly for preservation and presentation. Such beautiful stamps should not be kept in hiding. So the question is, where to buy reasonably priced, but archival quality sheet protectors for stamp sheets? One thing I do know is they cannot be a vinyl based product. Thanks!

- I would try a store that provides scrabook supplies. All of that is achival. There are several sizes of page protectors available.

- Q: What are the kinds of plastic sheets and the use of plastic sheets?

- Polyethylene plastic sheet (PE plastic board).Uses: widely used in chemical, mechanical, chemical, electrical, clothing, packaging, food and other industries. It is widely used in gas transportation, water supply, sewage disposal, agricultural irrigation, mine fine particle solid transportation, oil field, chemical industry, post and telecommunications, and so on. It has been widely used in gas transportation.

- Q: What do you call the plastic sheets that x-ray s are embossed in?

- They are called negative plates.

- Q: I had a pilonidal cyst removed from my natal cleft (aka butt crack) last Tuesday, and to reduce the risk of infection, the surgeon used surgical glue to close the wound's exterior, and a sheet of super-sticky surgical plastic to keep my cheeks together and provide another layer of protection from infection.Well, it started peeling up a bit at the top and bottom and letting some air get to the would, so I peeled off a little bit and trimmed it off (with help, lol). I went as far as I dared to, but I just hit a part where it hurt. I'm concerned about infection getting to the spots where air had already made it in, but I also don't want to open the wound.I don't have an appointment with my surgeon until Thursday- do you think it would be okay to wait for him to remove it, or should I just use some Vaseline to take the rest of it off now?

- Put some antibiotic ointment on it (neosporin etc). That will not only kill any bacteria that might be trying to get into the wound, but it will also loosen the stickiness of the tape, so that it comes off easily on its own without further injury. Put the ointment, then leave it alone until the doc sees it.

- Q: Can I use all these plastics sheets and duct tape I bought after 9/11 to protec me from e. bola?

- Exemplary discourse my cohort

- Q: Can I use wallpaper paste to stick gravel to plastic sheeting?I want to make, as cheaply as possible, a Sempervivum roof for a bee house in my garden and thought I could us a plastic sheet, gravel stuck on that, then earth and the plants.What's the easiest and less smelliest (bees don't like smells) glue I can use? Will wallpaper paste do?Thanks for reading.

- Wallpaper paste will not work in this application. It will turn to mush again as soon as moisture gets to it. Most adhesives that apply in liquid form will not work well, and almost all will have smell that remains for some time One adhesive that would work well both on plastic sheeting, have virtually no smell, and will remain solid under dirt is hot glue, but application is time-consuming, and you will have to be careful with the application temperature, as it has to stick onto the plastic, but not melt through it. A heavy-grade plastic sheet will be needed/ You have some choice in the melt points of the glue stick and can ask at the store about the lowest melt sticks they have. . The easiest solution to this might be a small craft-store glue gun and buy the sticks from them (or a dollar store) as they only use glue sticks that have a low melt point Before beginning your main work, practice applying the glue on a spare part of the sheeting and see how quickly you can work with it,

Send your message to us

PVC Foam Board and Sheet Raw Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 1000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords