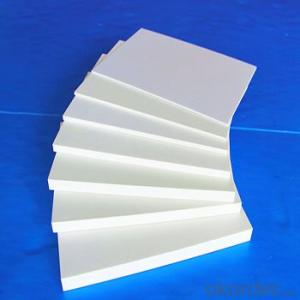

PVC Celuka Foam Board Plastic Sheets - PVC Forex Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2.Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Usage life: more than 50 years

Hardness:>10Mpa

3.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4.Product Application

①Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

②Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating,etc.

③Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

④Chemical anti corrosion project, special cold project, environmental protection.

5.pictures of factory

6.FAQ

Q: Are your samples free of charge?

A: Yes,Samples are arranged upon request within 3 workdays

Q: Can we visit your company to inspect products before delivery?

A: You are welcome to visit our company to inspect us and our products.

Q: Do you accept test order?

A: Yes,we accept test order before you place a big formal order with us.

- Q: Are plastic sheets resistant to warping due to temperature fluctuations?

- Yes, plastic sheets are generally resistant to warping due to temperature fluctuations. However, the specific type and quality of plastic used can affect their resistance.

- Q: They need to be non-adhesive.

- Spray it with acrylic wax

- Q: How do plastic sheets compare to glass or acrylic?

- Plastic sheets, such as polycarbonate or PVC, offer several advantages over glass or acrylic. Firstly, they are much more durable and resistant to impact, making them ideal for outdoor or high-traffic areas. Plastic sheets are also lighter in weight, making them easier to handle and install. Additionally, plastic sheets are more cost-effective compared to glass or acrylic. However, glass and acrylic have better optical clarity and scratch resistance, making them suitable for applications where aesthetics and visibility are crucial. Ultimately, the choice between plastic sheets, glass, or acrylic depends on the specific requirements and priorities of the project.

- Q: Can plastic sheets be used for shower doors?

- Yes, plastic sheets can be used for shower doors. They are a cost-effective alternative to glass doors and offer similar functionality. However, plastic sheets may not provide the same level of durability and aesthetic appeal as glass doors.

- Q: hi everyone. making an outdoor sign for a school art/craft fair. have a plastic sheet with a nutcracker on it. want to adhere it to some plywood but dont want it to rip in the weather/ wind. i tried gorilla glue but it worked only so so. any good ideas are appreciatedthanks all

- there is a spray glue avaliable not sure of its name , try your local hardwear store or homedepot and tell them what you are doing they will set you up good, have fun with the fair.....

- Q: Pink fiberglass insulation comes either faced or unfaced. On DIY shows on TV, I almost always see people using unfaced insulation and putting a sheet of plastic visqueen over the studs, rather than using faced insulation and not needing visqueen. Which method is better?

- Visqueen Plastic

- Q: I think the cheese slices that are not placed in these individual plastic sheets tastes better. Why do they do this?

- Convenience is an important feature of their brand.

- Q: Are plastic sheets safe for food contact?

- Yes, plastic sheets are generally safe for food contact as long as they are made from food-grade materials that are free from harmful chemicals and toxins.

- Q: Are plastic sheets scratch-resistant?

- Yes, plastic sheets can be scratch-resistant depending on their composition and manufacturing process. Some types of plastics, such as polycarbonate or acrylic, are specifically designed to have scratch-resistant properties. However, it is important to note that not all plastic sheets are scratch-resistant, so it is necessary to choose the right type of plastic sheet for specific requirements.

- Q: Are plastic sheets resistant to breakage from heavy objects?

- Yes, plastic sheets are generally resistant to breakage from heavy objects due to their durability and flexibility.

Send your message to us

PVC Celuka Foam Board Plastic Sheets - PVC Forex Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords