PVC Celuka Form Board Plastic Sheets - PVC Free Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

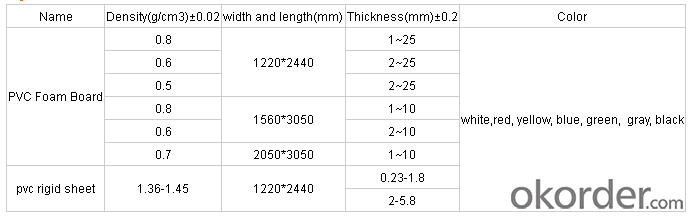

2.Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43- 0.9mm

3.Product Features

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

4.Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

5.Pictures

6.FAQ

Q.Which factors can be customized?

A: Material, Color, Size, Packing ,Brand, delivery

Q:Advantages of your products?

A:Company products, good quality, high reputation guarantee.

- Q: I have a dinning room table that expands to 102 inches when the leaves are added. That length also means I have to spend a lot of money on a single table cloth! I think they call that banquet size.With fine linens, like everything else, costing so much these days, I really don't want Uncle Jim's red wine or Aunt Sara's coffee to totally ruin the table cloth if they spill. Not to mention, spills always seem to happen outside of a place mat.So is it really that uncool to put a non-shiny thin plastic...... something-or-other over the table cloth?

- quite being cheap and by a table cloth

- Q: Is PVC plastic board afraid of sunlight?

- PVC ceiling generally add 200 copies of calcium, plus less, they have no profit, next time buy that kind of film.

- Q: Can plastic sheets be used for aquariums?

- Yes, plastic sheets can be used for aquariums. However, it is important to ensure that the plastic used is safe for aquatic environments and does not release any harmful substances into the water. Acrylic and polycarbonate are commonly used plastic materials that are suitable for aquariums due to their strength, transparency, and resistance to water.

- Q: Are plastic sheets water-resistant?

- Yes, plastic sheets are typically water-resistant.

- Q: What are the different types of plastic used in plastic sheets?

- There are several different types of plastic used in plastic sheets, including polyethylene, polypropylene, polyvinyl chloride (PVC), polycarbonate, and acrylic. Each type of plastic has its own unique properties and characteristics, making them suitable for various applications.

- Q: I need a piece of flat sturdy plastic about 1/8 thick. Does anybody know where I can buy this? I dont want plexiglass, its too expensive.

- You okorder / okorder / GOOD LUCK !!

- Q: I have an 08 Hyperlite Era board that has a big problem. the top plastic sheet is peeling off at the edges and it is dragging in the water bad. i dont want to buy a new board but i cant fix it. I have already tried a permanent epoxy-resin but it was destroyed after the first use. I am now thinking of shrink wrapping a resin type plastic onto the whole edge but i dont know what i am doing. Does anybody have any suggestions?

- The easiest way is to joint compound over the peeled areas, then sand (wet sanding is much neater) prime and paint. If the damage is really bad, you'll have to cut out the bad piece, screw in a new one, tape the seams, then sand and repaint.

- Q: i am working on an art project and I am wondering if there is a crafty type way for me to transfer the typed text from one sheet of paper to another (like to lift the ink off the paper somehow). I am not concerned about the words being recognizable or readable, I just like the aesthetic of words that don't necessarily mean anything mixed with pictures. thanks!

- It's called a photocopier. Photocopy the page onto a sheet of transparent plastic. Then lay the plastic over the new sheet where you want the letters to appear. If you don't want the plastic, the process is trickier. It still can be done. Photocopy the page onto plastic as before. Then lay the photocopied plastic sheet reversed on the photocopying glass. Copy onto a piece of paper. The result will be a sheet of paper with the letters reversed. Since photocopiers use toner that is baked onto the page, you need to take the sheet with reverse lettering and iron (using a hot iron) the reversed lettering onto the page you want it to appear. Since you are reversing a reversal, the result will be correct left-to-right. It might take several tries to get the technique down right, but it is do-able. Whether it is worth it, you'll have to determine.

- Q: Are plastic sheets resistant to bending under weight?

- Yes, plastic sheets can be resistant to bending under weight depending on their thickness and composition.

- Q: What are the different types of plastic sheets available?

- There are numerous types of plastic sheets available, including acrylic, polycarbonate, PVC, ABS, HDPE, and LDPE. Each type has unique properties and characteristics that make them suitable for various applications such as signage, packaging, construction, and fabrication.

Send your message to us

PVC Celuka Form Board Plastic Sheets - PVC Free Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords