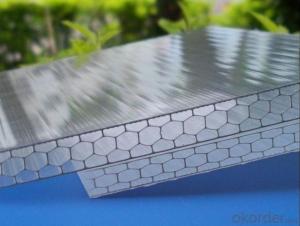

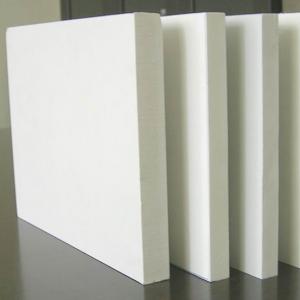

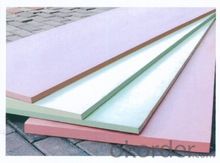

Plastic Sheets - PVC Sheet, PVC Celuka Foam Board, PVC Cabinet Foam Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

FAQ

Q1. What is your terms of packing?

PVC foam board are packed in plastic film , then in Carton ,wood pallet or according to customers' requirements

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 5 to 10 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Features:

1. Moistureproof, waterproof, shock absorption and mothproof

2. Fire retardant and self-extinguishing, Heat preservation

3. Sound insulated

4. Insulation

5. Perfect chemical corrosion resistance, good resistance to UV & weathering Non-toxic

6. Non-deformation

7. Non-formaldehyde emission

8. Stable color retention

9. surface is very smooth, rigid and not easy to scratch. Uniform fine & close cell structure

10. same processing as timber, but processing performance is much better than wood

11. Light weight, easy and convenient to storage, transportation and use

12. It is machinable could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

13. Smooth surface and suitable for silkscreen printing, laser engraving (must clean the surface before printin

Our Service

1. We offer samples for free, buyer only need to pay express fee, if you make a order from us finally, we will subtract the express fee from total amount

2. Through Alibaba Trade Assurance finish the order, we will give additional 1% discount

3. Trial order can be accepted

4. If you need, welcome to visit our factory and examine cargo

- Q: Are plastic sheets resistant to discoloration from sunscreens?

- Yes, plastic sheets are generally resistant to discoloration caused by sunscreens.

- Q: What is the thickness range available for plastic sheets?

- The thickness range available for plastic sheets can vary greatly depending on the type of plastic. However, commonly available plastic sheets can range from as thin as 0.01mm to as thick as 25mm or more.

- Q: Can plastic sheets be glued together?

- Yes, plastic sheets can be glued together using various types of adhesives specifically designed for bonding plastics.

- Q: Are plastic sheets resistant to scratches?

- Yes, plastic sheets are generally resistant to scratches due to their durable and tough nature. However, the level of scratch resistance may vary depending on the type and quality of the plastic sheet.

- Q: Are plastic sheets resistant to bending under heavy loads?

- Yes, plastic sheets are generally resistant to bending under heavy loads, especially those made from high-density polyethylene or polycarbonate. These materials have excellent strength and flexibility, allowing them to withstand considerable pressure without bending or breaking.

- Q: Can plastic sheets be cut to size?

- Yes, plastic sheets can be cut to size.

- Q: What is acrylic? Is it plastic? What's the difference between good and bad?

- If plastic is difficult to judge from its appearance, it can only be found in the process of injection or manufacture.Finished products, generally from the appearance (such as transparent test) and their own hand test, hardness, toughness and so on, you can have a certain resolution.

- Q: What are my options? What's the name of these type of plastics?Id like to buy in bulk, raw sizes to get the lowest price possible..

- Try your local Office Depot, or Staples. They should have what you are looking for and if not they can tell you where you can get them.

- Q: Are plastic sheets scratch-resistant?

- Yes, plastic sheets can be scratch-resistant depending on their composition and manufacturing process. Some types of plastics, such as polycarbonate or acrylic, are specifically designed to have scratch-resistant properties. However, it is important to note that not all plastic sheets are scratch-resistant, so it is necessary to choose the right type of plastic sheet for specific requirements.

- Q: Every morning I wake up and when I see it looks like there is a piece of plastic over my eyes. After a few minutes it goes away. Whats wrong??

- You are probably tired and need more rest before getting up. It would be best to ask your eye doctor.

Send your message to us

Plastic Sheets - PVC Sheet, PVC Celuka Foam Board, PVC Cabinet Foam Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords