pvc celuka foam board/20mm pvc rigid foam board/3mm pvc foam board for advertising printing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

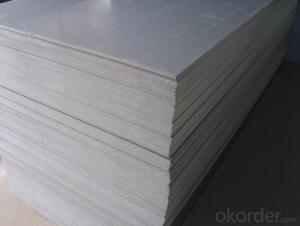

We are specialized in manufacturing PVC foam board.

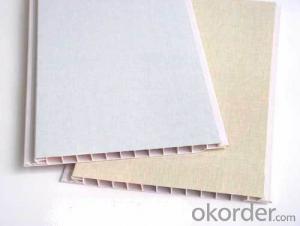

Standard Size We Provide as below:

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Specifications

Size:1220*2440mm and other size

Thickness:1-5mm

Density: 0.5-0.9g/cm3

Surface: smooth and rigid

foam board advertising priting | |

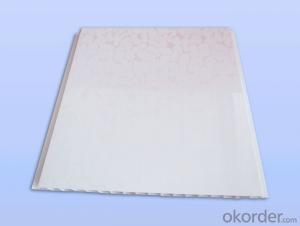

Introduction | PVC Foam Board is the new man-made material, the main component is PVC, it has the fine chemical stability, anti-corrosive and high intensity, it can be the substitute of wood, it is widely used in the building, advertisement and decoration. |

Thickness | 1-5mm |

Length | As your request |

Density | 0.5-0.9g/cm3 |

Size | 1220*2440mm,1560*3050,2050*3050mm and so on |

Color | white |

Package | Wooden pallet outside and plastic bag,or as your request |

Delivery | Received the order within ten days |

Payment Terms | 30% T/T in advance,70% T/T balance before shipment |

MOQ | 1 ton |

Applications | 1.Building outdoor wall board, indoor decoration board, partition board in office and house 2.Screen printing, flat solvent printing, engraving, billboard and exhibition display. 3.Chemical anticorrosion project, special cold project, environmental protection |

Features

| 1. Waterproofing. 2. Fire retardant and self-extinguishing. 3. Heat preservation. 4. Sound-insulated. 5. Insulation. 6. Non-corrosion. 7. Non-toxic. 8. Tough, rigid with the high impact strength. 9. Stable color retention. |

We can provide you:

1)Free sample

2)Fast delivery

3)We appreciate customers give us any feedback or suggestion for products.

4)If any replacement, we will do the best way and make shipment in time

5)We provide new styles to all our cooperated customers, also you're welcomed to visit our websites to view new styles.

6)We are glad to help our customers to make any promotion any time.

Applications :

-Advertising Signs

-Displays

-Exhibition Stands

-Point of Sale

-Interior Designs

-Bathroom Fittings

-Models & Prototypes

-Panels & Cabins

-Embossing & Engraving

-Thermoforming

-Lumber

-Trimboard

PVC Foam Sheet Features:

1) Lightweight, goodtenacity, high rigidity

2) Fireproof and flame retardant

3) Goodinsulation

4) No sopping, no deformation

5) Easy to process

6) Goodplasticity, is an excellent thermoform material

7) Sub-light surfaceand elegant vision

8) Anti-chemical corrosion

9) Suitable for silkscreen printing

10) With imported dyes, unfading and anti-aging

FAQ

1. If the products have some quality problem ,how will you deal with it?

Answer : If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

2. Is free design assistance available for clients?

Answer : If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.Pictures

- Q: Can plastic sheets be used for stage props?

- Yes, plastic sheets can be used for stage props. They are versatile, lightweight, and can be easily manipulated into various shapes and forms to create the desired effect for a stage production.

- Q: What is the difference between EPS insulation board and XPS insulation board?

- Polystyrene board (EPS) is a kind of foam material with closed cell structure formed by foaming and molding with polystyrene resin as its main component.Extruded board (XPS) is a rigid foam material with a closed cell structure made of polystyrene resin or its copolymer as the main component, adding a small amount of additives and heating and extruding.

- Q: I want to renovate my basement, but as I was walking through my local hardware store, I noticed a variety of sheetrock that are mold resistant to fire resistent and at different thicknesses. Is a thicker board better for the basement?Also, is there a way to test moisture in a basement over sheetrock or would I have to remove the sheetrock and apply a plastic sheet with tape to test for moisture?thanks!

- You should really use mold retardant sheetrock in the basement. It might actually be required by code depending on where you live. I helped a guy fix up a house and the inspector told him to sheetrock the ceiling of the basement and use 1/2 mold resistant sheetrock. The differences you get with thickness of sheetrock is mostly durability. Obviously thicker sheetrock will hold up longer. On ceilings especially, the 3/8 inch sheetrock will bend over time between the rafters (or floor joists in the basement) where it is screwed in. There is also a difference in sound-proofing, you hear less through walls of 5/8 than 3/8. The last difference is fire resistance, 5/8 inch sheetrock takes significantly longer for fire to burn through than 3/8. To chose which one you want to use, find out what the code requires in your area. You may be required to use mold resistant sheetrock, or you may be required to use fire resistant boards. I would use 1/2 in the basement because it is a lot easier to hang than 5/8 and you have decent durability and unlike 3/8, it will not bend or bow over time. I actually saw mold resistant fiber tape for the joints in The Home Depot, you might want to use that whether or not it's required by code just for extra measure. Some things may be more expensive to do to the tee, but if you cheap out now, you may end up pending more fixing things if they go wrong or get messed up later down the road. And most importantly, do every single thing to code and pull permits for everything, that way you are covered on all your bases.

- Q: Ok i have a large entertainment center that was custom built and one of my 2 young girls has damaged the existing plastic mesh inserts that go inside the bottom doors. They are thin black plastic about 2 foot by 2 foot each, with many little holes (like a mesh) for the sound of the speakers to come through. I have looked all over the web for a simular material but havent had any luck finding anything. I dont care if i have to buy raw material that i have to paint or cut. I would just like to know if anyone knows where to find a material like this?

- in a home store, there's a product at the 'window screen' area.... it's called pet screen... it's black plastic mesh.... I use it in my pond, too!....all kinds of uses!!... besides screen, that is.... works good that way, too!

- Q: Are plastic sheets resistant to cracking in freezing temperatures?

- No, plastic sheets are not generally resistant to cracking in freezing temperatures.

- Q: What are we up to?

- Um, re-enacting a scene from 9-1/2 Weeks??

- Q: Can plastic sheets be used in medical applications?

- Yes, plastic sheets can be used in medical applications. They are commonly used for various purposes such as protective barriers, packaging, disposable equipment, and medical device components. Plastic sheets offer qualities like flexibility, durability, and resistance to chemicals, making them suitable for medical settings.

- Q: What's the difference between a TK board and a plastic board?

- The hardness of material plastic plate deep processing is not only simple KT board cut and paste.

- Q: Are plastic sheets impact-resistant?

- Yes, plastic sheets can be impact-resistant depending on their composition and thickness. Some types of plastics, such as polycarbonate and acrylic, are known for their high impact resistance and are commonly used in applications where durability and protection are required.

- Q: Are plastic sheets resistant to chemicals in swimming pool environments?

- Yes, plastic sheets are generally resistant to chemicals in swimming pool environments. They are commonly made from materials such as polyethylene or PVC, which have excellent chemical resistance properties. These plastics can withstand exposure to chlorine, bromine, and other pool chemicals without significantly degrading or corroding. However, it is important to note that prolonged exposure to certain harsh chemicals or extreme temperatures may still cause some deterioration or discoloration over time.

Send your message to us

pvc celuka foam board/20mm pvc rigid foam board/3mm pvc foam board for advertising printing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords