PVC Celuka Foam Board with Different Density Thickness Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

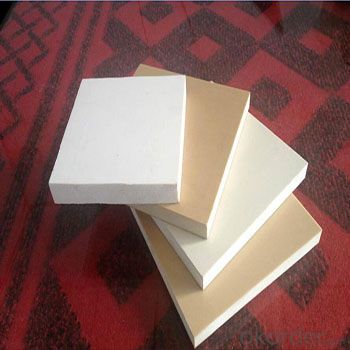

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

| product name | PVC Foam Board/PVC Foam Sheet |

| Density | 0.43-0.9g/cm3 |

| Thickness (mm) | 1 ~ 33mm |

| Capacity | The capacity is 10000 tons/month PVC foam board |

| Main Size (mm) | 1220*2440mm,1560*3050mm,2050*3050mm (Special dimensions can be made by customer’s requests) |

| Colors | white,black |

| Certification | QC ,SGS,PONY |

Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

1. How&When can I get the price?

Email us your inquiry or communicate online, state your specifications (product, material, size, quantity etc.). We usually quote within 6 hours. Please call us or inform in your email when it is urgent, we will regard your inquiry priority.

2. How can I get samples?

We provide samples per your requests. Sample charge required and freight collected. Sample charge refundable after order placed and the quantity reaches the requirement. Free sample provided of which products already existed or easy to make.

3. How much is the freight of samples?

Freight depends on the weight, packing size, destination, delivery carrier. DHL, FEDEX, UPS,TNT account is preferred.

Product details

- Q: Can plastic sheets be used for display cases?

- Yes, plastic sheets can be used for display cases. They are often used due to their transparency, durability, and cost-effectiveness. Plastic sheets, such as acrylic or polycarbonate, are commonly used to create protective barriers for displaying and showcasing various items in museums, exhibitions, retail stores, and other settings.

- Q: it touched a plastic bag right when it came out of the oven and now it's stuck on and hard as a rock. how do i get it off?

- You can do it allot of ways the simplest Soak it in hot sudsy water for 10-15 minutes then scrub it should come off easily Put it back in the oven (plastic side up) and let it heat up enough to melt then whip it off with newspaper or paper towels (be careful not to burn yourself) Or pop it in the freezer over night which should make it brital and just hit it really hard (smack it on the floor, hit it with a hammer) and it should brake off but this way is messy

- Q: I want to make my own slip and slide tomorrow and i am going to use some plastic drop sheets.But i need to find a shop to get it for tomorrow. Anyone know of large retail shops that sell them? Thanks

- home depot, lowes. look for plastic cover for painting, they sell different thickness of plastic. but why not just buy a slip and slide, might end up being less expensive.

- Q: POM what's the plastic board for?

- For instance:1, POM has a high hardness and steel;2 and POM have good anti creep and stress relaxation ability;3, POM has excellent wear resistance, self lubrication and fatigue;4 and POM have good dimensional stability, low water absorption and little influence on mechanical properties;The dielectric constant and dielectric loss tangent of 5 and POM vary little and have good dielectric properties.

- Q: Can plastic sheets be used for protective screens?

- Yes, plastic sheets can be used for protective screens. They are commonly used as barriers or shields to prevent the transmission of germs, dust, or other particles.

- Q: Extrusion plate fire B1, B2 grade materials, how to distinguish?

- Tight closed cell structure due to continuous extrusion. Its density, water absorption, thermal conductivity and steam permeability are lower than other types of sheet materials, is currently recognized as the best insulation material market.

- Q: What are the temperature limits for plastic sheets?

- The temperature limits for plastic sheets vary depending on the type of plastic. However, most plastic sheets have a temperature range of around -40°C to 80°C (-40°F to 176°F).

- Q: Can plastic sheets be used for 3D printing?

- Yes, plastic sheets can be used for 3D printing, specifically in a process called "laminated object manufacturing" (LOM). LOM involves cutting or laser-cutting plastic sheets into layers, which are then glued or fused together to create a 3D object. While this method is less common than other 3D printing technologies, it is still a viable option for certain applications.

- Q: I have a house in an area (southern Ontario) that is subject to wind-storms. I want to enclose my side porch in plastic so that I can smoke there - I just had a baby and can't smoke inside anymore. I put up 5 mm plastic with staples and strapping wood held up with finishing nails, but in the first wind-storm most of it came down. Would tarps work better? I can't afford to do it in properly with lattice and plywood right now, although that is my ultimate goal. Also I am alone here with my baby, my husband is a long-hauler and I need to be able to do this myself. I can operate a nail gun, a skil-saw, a staplegun. Please advise!

- When I lived in Minnesota we used to do that; we put some extra wood across the windows in an X, and sealed it also with tape. It should be fairly tight, or the wind will flap it and tear it, too.

- Q: How do I get rid of the static in the stack of the clear plastic cover sheets? Every time I try to pull one, I get shocked viciously!!It's within the entire stack. Help!

- Staticide. okorder /

Send your message to us

PVC Celuka Foam Board with Different Density Thickness Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords