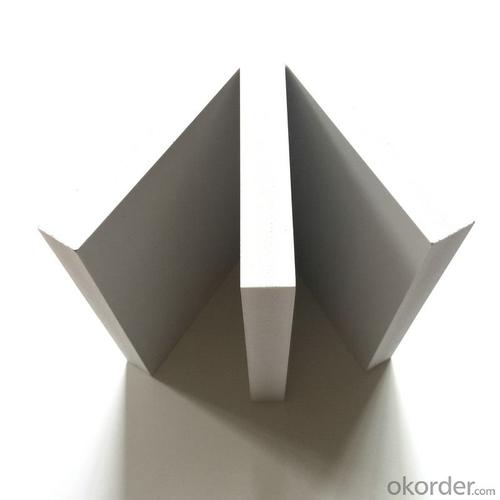

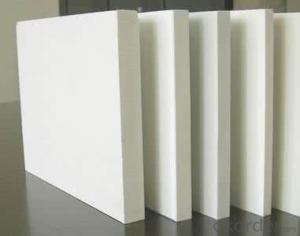

WHITE rigid celuka PVC foam board, PVC sheet, PVC printing material

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

WHITE rigid celuka PVC foam board, PVC sheet, PVC printing material

Product Description

Thickness:1-30mm;

Widhth:1250mm in Max;

Length:Any length;

Density:0.35-0.8g/cm3

Size;1220mmx2440mm,We can also produce special size accourding to customer's request;

Colour:White,gery,black,blue,green,orange,red,pupleand any othere colours according to customer's requirments.Also can be ordere according to the RALcolor card.

WHITE rigid celuka PVC foam board, PVC sheet, PVC printing material

Characterstic:

1. WHITE rigid celuka PVC foam board, PVC sheet, PVC printing material with flame retardant ,self-extinguishing,safe to use;

2.Light,tough,rigid with a high impact stregth;

3.Nontoxic and tasteless;

4.Fire-retardant,sound insulation,hot insulation;

5.Water-proofand mould-proof;

6.Color-fast,easy to wash;

7.Can be printed,cut,sawed,nailed,excavated and welded agglutinaton.

WHITE rigid celuka PVC foam board, PVC sheet, PVC printing material Specifications:

| 1 | product | White rigid celuka pvc foam board,Pvc sheet ,Pvc printing material |

| 2 | Size | 1220mmX2440mm,customized |

| 3 | Thickness | 1.0-30mm |

| 4 | Density | 0.35-0.8g/cm3 |

| 5 | Brand | Xingxiangrong |

| 6 | Color | White,Black,Red,Green,Pink,Grey,Blue,Yellow,etc |

| 7 | Executive | QB/T 2463,1-1999 |

| 8 | Certificate | ISO9001 |

| 9 | Weldable | Yes |

| 10 | Foam | Celuka |

| 11 | Water | <1%< td=""> |

| 12 | Tensile | 12-20Mpa |

| 13 | Elongation | 15~20% |

| 14 | Vicat | 73~76 °C |

| 15 | Impact | 8~15KJ/m2 |

| 16 | Shore | D75 |

| 17 | Flexural | 800~900MPa |

| 18 | Bending | 12~18MPa |

| 19 | Life Span | >50 years |

| 20 | Flame retardance | self-extinguishing less than 5 seconds |

- Q: Solid wood furniture and panel furniture which pollution is small?

- Popular, solid wood furniture is certainly a small pollution, but the market is full of a lot of parallel imports of solid wood furniture, such as solid wood paste, obviously the middle of the particleboard, posted a bark on the outside that is solid wood furniture, furniture and sheet furniture in my It seems there is no difference, choose a good solid wood furniture from the material, technology point of view. General people think that solid wood furniture is certainly all solid wood, but simply not, so when you buy furniture to ask the material, all parts of the material to ask, there is a desktop is solid wood, table legs are not, some desktop is good Wood, table legs with parallel wood, but the price tag is good wood price. Anyway, if you are very stressed that pollution is small, you will see manufacturers have no 10 ring certification, which is the most authoritative environmental certification, of course, people have money to buy another matter on the matter. You'd better buy a brand name, so safe, because to tell the truth, many small workshops which produce furniture, and then to the supermarkets to pay a long lease, transformed into a good furniture, and is completely deceptive. There is to shop around!

- Q: What is the meaning of furniture material E1MDF?

- Advantages of MDF MDF surface smooth and smooth, fine material, stable performance, the edge of a solid, and the decorative surface of the board is good. But the density of the board is less tolerant of moisture, and in contrast, the density of the clamping force of the board less than the particle board, screw tightening if the loose, because the density of the board is not high, it is difficult to fix. 1, MDF is easy to finish processing. A variety of coatings, paint can be evenly coated on the MDF, is the preferred substrate for the effect of paint. 2, MDF is a beautiful decorative plate. 3, all kinds of veneer, adhesive film, decorative panels, light metal sheet, melamine board and other materials can be affixed to the MDF surface. 4, hard density board by punching, drilling, can also be made of sound absorption board, used in architectural decoration works. 5, excellent physical properties, material uniformity, there is no dehydration problem.

- Q: Welding 1.2 plate should be used in what diameter of the electrode and the current strength?

- Welding 1.2 mm sheet, electrode diameter and current strength and other parameters are as follows: ?? ZX7 inverter DC welding machine (with the characteristics of arc stability, compared to the welding machine is more suitable for thin pieces of welding), the use of reverse (ground clamp negative pole, welding clamp positive +) polarity. ?? Electrode: 2.5 mm in diameter (the market is relatively easy to buy, theoretically diameter 2.0 electrode is difficult to buy to, and the price is much more uneconomical), welding current between 65-75 amps. ?? Welding methods and precautions: the electrode as far as possible tilt angle (to avoid the arc blowing on the formation of 1.2 plate burning), the use of rapid spot welding (arc welding), can not even arc welding, or will burn. With a cap to observe the molten pool cooled to less than the welding rod diameter re-arc welding.

- Q: Millennium mill plate is good or the new millennium plate is good

- The new millennium is the king coconut group under the well-known domestic brands, fame may not thousands of years of large, it is not wasting thoughts on the minds of the mind spent on the quality of the new millennium is not a brand of goods factory specializing in the production of this brand, the other It is not to say, buy bad also buy an OEM goods you injustice injustice, anyway, we are all with the new millennium, on their own home watching the factory getting bigger and bigger, we believe that seeing is believing , Listen to the evaluation of the workers inside.

- Q: What are the differences between FR5 sheet and FR4 sheet?

- FR-5 has a better advantage than FR-4: 1, TG, TD higher; 2, heat resistance is better, about twice the normal FR-4; 3, Z-CTE smaller, suitable for high multi-layer board; 4, T288 better. FR4FR5 epoxy board by a special electronic cloth impregnated with epoxy phenolic resin and other materials by high temperature and high pressure hot plate made of laminated products. With high mechanical properties and dielectric properties, good insulation properties and heat resistance and moisture resistance, and a good mechanical processing. Application: for electrical and electrical equipment for the insulation structure of parts, also widely used In the PCB test; and can be used in humid environmental conditions and transformer oil. Specifications:. Plate: Thickness x Width x Length = 0.3 ~ 50mmx1020mm x 1220mm

- Q: Jumping rabbit plate quality is good

- Jumping rabbit plate good rubber is not how kind, thin, but also with a little edge skin, the overall use of the down is not how

- Q: What are the top ten brand names in 2017?

- New Zealand Chi cabinet sheet using the new water-based polymer isocyanate gum, Environmental protection level to the highest national E0 standard, it belongs to the non-formaldehyde series, Completely away from the formaldehyde, benzene and other harmful substances on the human body harm, While preserving the aroma of natural logs

- Q: Home decoration cabinet made with what plate is good? How is the Malacca plate?

- City people decoration business know the platform for you to answer: In general, the main use of the following cabinet to do the following: UV board :, (advantages: waterproof and moisture-proof effect is very good) (shortcomings: a single color, simple shape) Paint board: advantages: smooth lines, the surface is mild) (shortcomings: a long time easy to change color deformation) Ordinary Blister Board: (Advantages: Affordable, ...) (Disadvantages: modeling a single, people feel dull), but this board in foreign countries to buy better Solid wood: the original, the advantages of modeling, natural color, luxury and noble, but the price is high and not environmentally friendly, easy to clean Molded plate: modeling changeable, can be made of simple European style or modern style. Gold plate: the surface, the middle of the glass material, surrounded by aluminum alloy wrapping or other materials, not durable, but also a waste of materials But is Malacca wood plate, the color is yellow and white, material is soft, light, the domestic general for woodworking board core material. Malacca hard. High density. Finished products should not be deformed, but the water is relatively strong, the home is not suitable for tide.

- Q: My family smokers next to the installation of a natural gas using a firearm, the two appliances exhaust pipe close to the natural gas company in the safety inspection that is very dangerous, between the two exhaust pipe to use the same fire with fire Of the plate, but I do not know which type of plate to use, please know the answer. I am good to buy

- Paper gypsum board paper. Gypsum board is a gypsum paste for the sandwich, both sides of the paper for the face of a light plate. Paper gypsum board texture light, high strength, fire, moth, easy to process. Plain gypsum board for interior walls, partitions and ceilings. After the fire treatment of water-resistant plaster board can be used for the humidity of the room walls, such as the bathroom, kitchen, bathroom and other tiles, metal plate, plastic tile wall lining.

- Q: What is Guodong plate

- Guodong Group mainly produces medium density fiberboard, with an annual output of 300,000 cubic meters, widely used in furniture, wood flooring production. 2017 Guodong Group will add three new production lines from Germany, the production capacity will reach 100 million cubic meters or more, will become the largest domestic medium-density fiberboard manufacturing enterprises

Send your message to us

WHITE rigid celuka PVC foam board, PVC sheet, PVC printing material

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords