Pvc Aluminum Coil Stock - High Quality All Applications and Sizes Finished Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High Quality All Applications and Sizes Finished Aluminum Coils

l Product Specification

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

1050 | 0.19 | 0.16 | 0.03 | 0.03 | 0.02 | / | 0.03 | 0.01 | 0.01 | 99.52 |

1060 | 0.10 | 0.17 | 0.02 | 0.02 | 0.02 | / | 0.01 | 0.02 | 0.01 | 99.63 |

1100 | 0.75 | 0.13 | 0.03 | / | / | 0.02 | 0.02 | 0.03 | 99.02 | |

1200 | 0.80 | 0.04 | 0.03 | / | / | 0.07 | 0.01 | 0.04 | 99.01 | |

1 | Alloy | 3003 3004 3005 3105 |

2 | Temper | O H12 H14 H24 H16 H26 H18 H112 F |

3 | Thickness | 0.2mm-10mm |

4 | Width | 500-2200mm |

5 | ID | 508mm 405mm 305mm 150 mm 75mm |

6 | Standard | GB/T, EN, ASTM |

7 | Surface | Mill,Bright, polished, brush, checkered, embossed, etc. |

8 | Payment term | TT, LC, DP, western union, etc |

9 | Price term | EXW, FOB, CFR, CIF, etc |

10 | Export to | Singapore, Indonesia, Ukraine, Korea, Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq, Russia, Malaysia, etc. |

11 | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture,machinery parts, precision machining with the tubes, rods, shaped, sheet metal. |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirement

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

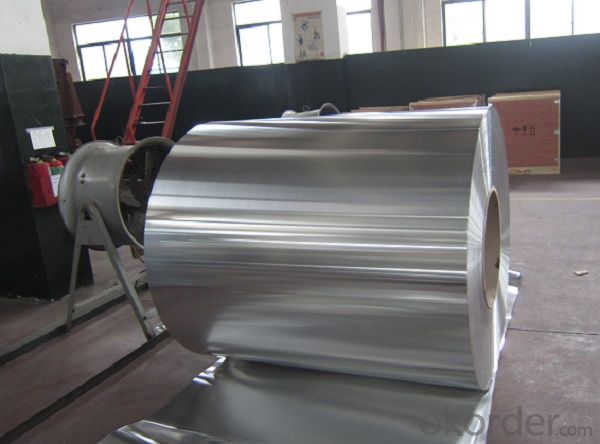

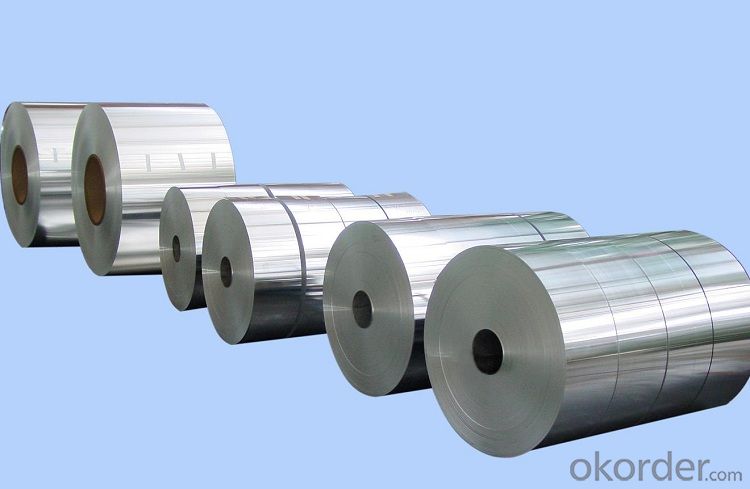

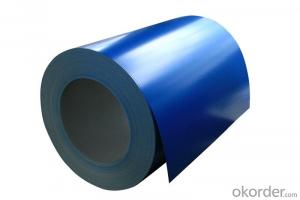

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: How do aluminum coils contribute to improved indoor comfort?

- The role of aluminum coils in enhancing indoor comfort through their contribution to HVAC systems is crucial. These coils are commonly utilized in air conditioning units and heat pumps to assist in the heat transfer procedure. The main purpose of aluminum coils is to extract heat from indoor air and expel it outside. As warm air passes across the coils, the aluminum absorbs the heat, causing the refrigerant inside the coils to evaporate. This evaporation process cools down the air, which is then circulated back into the room, resulting in a more pleasant indoor atmosphere. The utilization of aluminum for coil construction is advantageous because of its exceptional thermal conductivity properties. Aluminum demonstrates high efficiency in transferring heat, enabling the coils to promptly absorb and release thermal energy. This efficiency allows the HVAC system to cool down the indoor air more effectively and rapidly, thus improving comfort levels. Additionally, aluminum coils offer numerous advantages over other coil materials, such as copper. Aluminum is lightweight, making it easier for the HVAC system to operate efficiently. It is also resistant to corrosion, ensuring the longevity and durability of the coils. This corrosion resistance prevents the formation of contaminants or blockages that could hinder the heat transfer process, ultimately maintaining optimal indoor comfort. In conclusion, aluminum coils contribute to enhanced indoor comfort by facilitating efficient heat transfer in HVAC systems. Their ability to quickly absorb and release thermal energy, combined with their lightweight and corrosion-resistant properties, ensures a more effective cooling process, resulting in a comfortable indoor environment for occupants.

- Q: Difference between aluminium roll gate and iron roll gate

- and the iron roll gate weight, motor power, electricity, but the door of high strength, better safety performance.

- Q: I want to remove melted aluminium piston material from an engine cylinder with burning a hole in the cylinder!

- I am quite sure any acid strong enough to dissolve aluminium would be able to dissolve iron and steel, as acid + metal equations can be substituted with any metal and any acid.

- Q: What are the environmental regulations concerning the use of aluminum coils?

- <p>Yes, there are environmental regulations that govern the use of aluminum coils. These regulations vary by country and region but often include restrictions on emissions, waste disposal, and recycling requirements. For instance, in the United States, the Environmental Protection Agency (EPA) enforces rules that control the release of pollutants from aluminum production facilities. Additionally, there are guidelines for the proper disposal of aluminum waste to prevent environmental contamination. Recycling regulations also encourage the reuse of aluminum coils to reduce the environmental impact of mining and production. Compliance with these regulations is crucial for businesses that manufacture or use aluminum coils to avoid penalties and ensure sustainable practices.</p>

- Q: Can aluminum coils be used in pharmaceutical manufacturing?

- Yes, aluminum coils can be used in pharmaceutical manufacturing. Aluminum is commonly used in the pharmaceutical industry for various purposes, including packaging and manufacturing equipment. Aluminum coils can be used to make containers, caps, and closures for pharmaceutical products. These coils are often used in the production of blister packs, which are widely used for packaging tablets and capsules. Aluminum is preferred in pharmaceutical manufacturing due to its excellent barrier properties, resistance to corrosion, and ability to protect the integrity of the pharmaceutical products. Additionally, aluminum is lightweight, recyclable, and has a low melting point, making it a versatile and cost-effective choice for pharmaceutical manufacturing.

- Q: What are the different packaging weights available for aluminum coils?

- The different packaging weights available for aluminum coils vary depending on the specific requirements and applications. Common packaging weights for aluminum coils range from 1,000 to 10,000 pounds or more. These weights can be customized to meet the needs of different industries and transportation methods.

- Q: How are aluminum coils processed for further fabrication?

- Aluminum coils are processed for further fabrication through a series of steps to transform them into various products. The first step is typically uncoiling the coil to separate it into individual sheets or strips. This can be done manually or through an automated process. Next, the coils undergo a surface cleaning process to remove any dirt, oil, or other contaminants. This is important to ensure proper adhesion and surface finish in the subsequent fabrication steps. The cleaning process may involve chemical treatments, rinsing, or mechanical brushing. After cleaning, the coils are often subjected to a pre-treatment process, such as chemical conversion coating or anodizing. These treatments improve the surface properties of the aluminum, providing better corrosion resistance, enhanced adhesion for coatings, and improved paint adhesion. Once the pre-treatment is complete, the coils are ready for fabrication. This can involve various techniques such as cutting, bending, stamping, or roll forming. Cutting can be done through shearing, sawing, or laser cutting, depending on the required dimensions and accuracy. Bending and forming are commonly used to shape the aluminum coils into desired profiles or structures. This can be achieved through press brakes, roll forming machines, or specialized bending equipment. Stamping is another popular method of fabrication, where the coils are pressed into specific shapes using dies and punches. This technique is commonly used in the production of automotive parts, household appliances, and electronics. Once the desired fabrication is complete, the coils may undergo additional surface treatments or coatings to provide protection or enhance their appearance. This can include painting, powder coating, or applying protective films. In conclusion, aluminum coils are processed for further fabrication through a series of steps including uncoiling, surface cleaning, pre-treatment, cutting, bending, stamping, and surface treatments. These processes allow for the transformation of the coils into various products with the desired properties and characteristics.

- Q: What are the weight considerations when using aluminum coils?

- When using aluminum coils, weight considerations primarily involve the overall weight of the coils themselves and the impact it may have on transportation, installation, and structural support systems. Aluminum coils are preferred in various industries due to their lightweight nature, which enables easier handling and reduces the load on infrastructure. However, it is important to ensure that the weight of the coils aligns with the intended application and the capacity of the supporting structures. Additionally, factors such as coil thickness, width, and length should also be taken into account to determine the appropriate weight considerations when using aluminum coils.

- Q: i have recently received a task to research the recycling processes of aluminum ..... the task also asks to STATE ALL RELEVANT MATHEMATICAL OR/AND CHEMICAL EQUATIONS ...when i researched the task i found how aluminum is recycled, but i couldnt find the relevant equations ...can you please help meall answers are really appreciated

- Aluminium recycling is the process by which scrap aluminium can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy intensive than creating new aluminium through the electrolysis of aluminium oxide (Al2O3), which must first be mined from bauxite ore and then refined using the Bayer process.

- Q: Are aluminum coils suitable for automotive body panels?

- Indeed, automotive body panels can be effectively constructed using aluminum coils. The lightweight nature of aluminum greatly contributes to enhancing fuel efficiency and overall vehicle performance. Furthermore, the exceptional corrosion resistance of aluminum makes it an optimal selection for automotive applications, particularly when the panels are frequently subjected to diverse weather conditions. The impressive strength-to-weight ratio of aluminum further ensures outstanding durability and crash resistance. Moreover, aluminum allows for effortless formation and shaping, enabling the creation of intricate and fashionable designs. In conclusion, the utilization of aluminum coils for automotive body panels presents a multitude of benefits, making it a highly favored option for car manufacturers.

Send your message to us

Pvc Aluminum Coil Stock - High Quality All Applications and Sizes Finished Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords