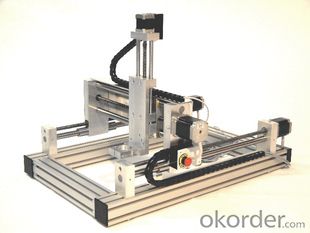

Professional cnc engraving machine for woods

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

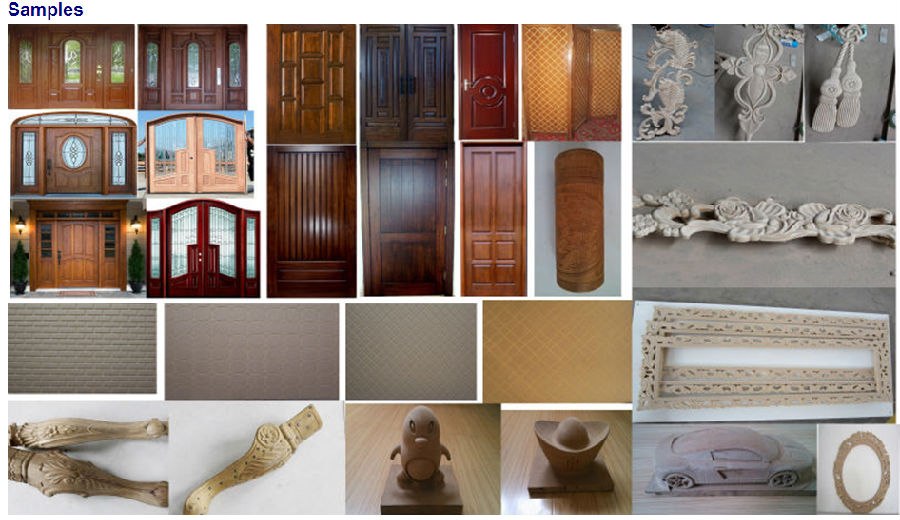

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

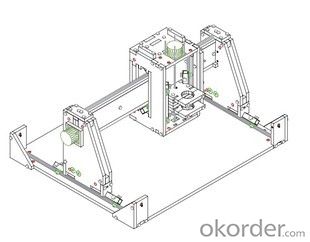

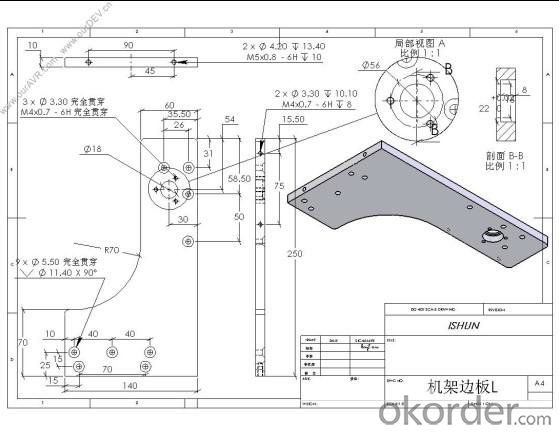

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q: When did the woodworking engraving machine start?

- CNC woodworking engraving machine, is probably the last century the beginning of 60s, the beginning of Longmen CNC milling machine, at the beginning of 80s, Italy and Germany do batch used in this and later, Japan, followed by Taiwan Province, in fact, many of those called domestic woodworking engraving machine is advertising engraving machine PRO version.

- Q: What is the maximum cutting depth of woodworking engraving machine?,

- Suggest that you change high-power spindle motor, but even so, hard wood or no one size fits all, at least two knives or more.

- Q: Bought their own carving machine, carpentry, violin code, with a lot of knives are broken knife, serious processing, not a few will be broken

- The production of the piano code is very complicated. Cheap piano code is cheap. You can not accurately calibration and grasp the angle and internal hollowed out, it will do harm to the tone of the piano. I hope I can help you

- Q: Woodworking computer engraving machine, how to do the Dragon scales?

- The dragon carved software in the first Linyao in painting, coloring, stacking, sit path output, have a few processes

- Q: What kind of wood do woodworking machines usually use?

- Phoebe, fine texture, straight texture, easy processing, good durability, smooth cutting surface, has a fragrance, is a precious timber used in ancient sculpture.

- Q: What are the principles and advantages of square rail helical gear drive for woodworking engraving machines?

- Woodworking engraving machine now mostly adopts the transmission side rail rack for processing, compared with the screw drive side rail rack combination original faster, more in line with the characteristics of small machine tools woodworking engraving rapid engraving and milling, and woodworking engraving machine is the standard Taiwan square straight line guide rail and high precision milling helical rack. Both processing speed and accuracy are much higher than other brands.

- Q: What's the head of a woodworking computer engraving machine?

- Carved relief with 3.17 flat knife, sold everywhere for relief, the key is that you will do relief map, ha ha, you need to go out to learn

- Q: Woodworking coffin engraving machine computer control system location, how to set parameters?

- In order to ensure the safe and convenient use of woodworking engraving machines, the operator can set three sets of parameters, and assist in the normal operation of tool change and tool setting. The three sets of positional parameters are the machine tool travel parameters, the tool change position and the tool position, and the position parameter setting. The three position parameters are related as follows:

- Q: Woodworking engraving machine platform suction shortage is what reason, what is the solution?

- In the use of woodworking engraving machine, causing the machine to absorb the table without suction, can not be adsorbed plates for the following reasons:1 、 whether the motor line voltage is normal;2, whether the water circulation pump water less, the motor is stuck, rust, remove the motor, fan protection network, rotating axis;3, vacuum pump filter, plug, clean up;4, the surface or pipe leak phenomenon trimming;5, positive inversion, change the motor, any two lines change the direction of the motor.

- Q: Precautions for woodworking engraving machines

- CNC woodworking engraving machine application scope: operators must be familiar with CNC woodworking engraving machine engraving plate range, familiar with different materials, different thickness, different finished product size, etc.. Be familiar with different materials in different ways of engraving.

Send your message to us

Professional cnc engraving machine for woods

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords