Professional latest cnc engraving machine for woods

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

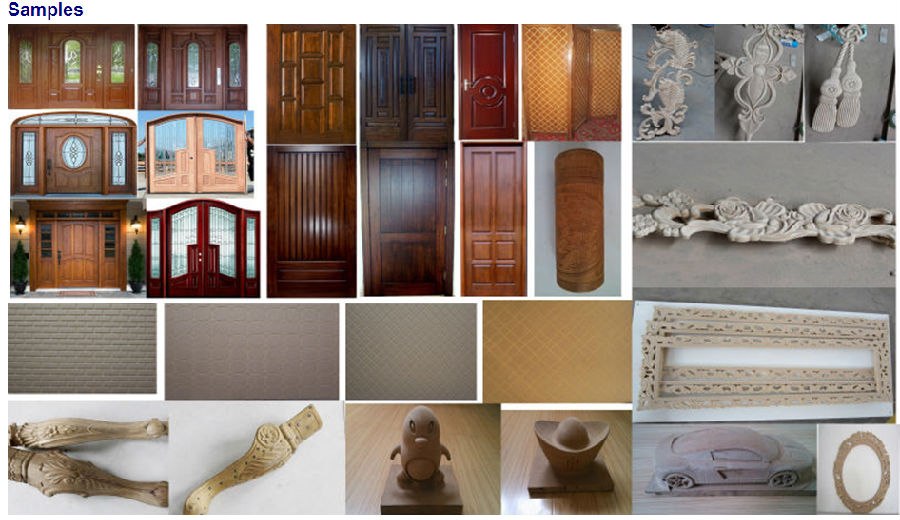

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

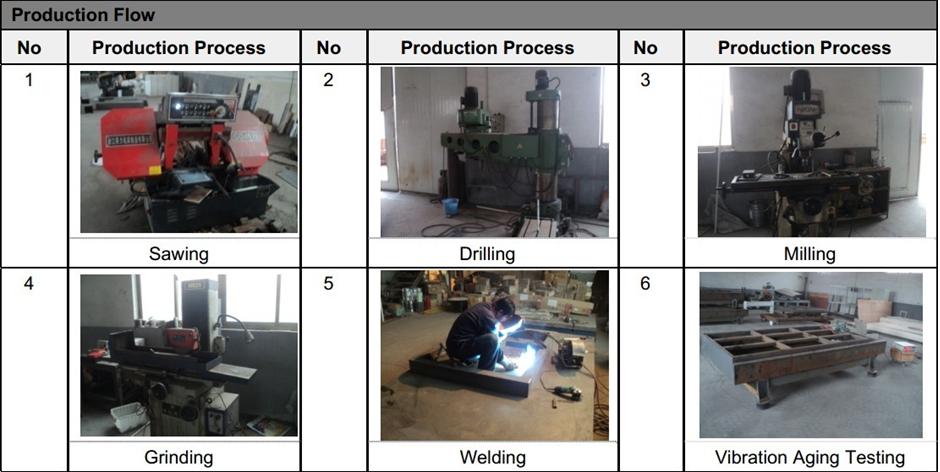

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

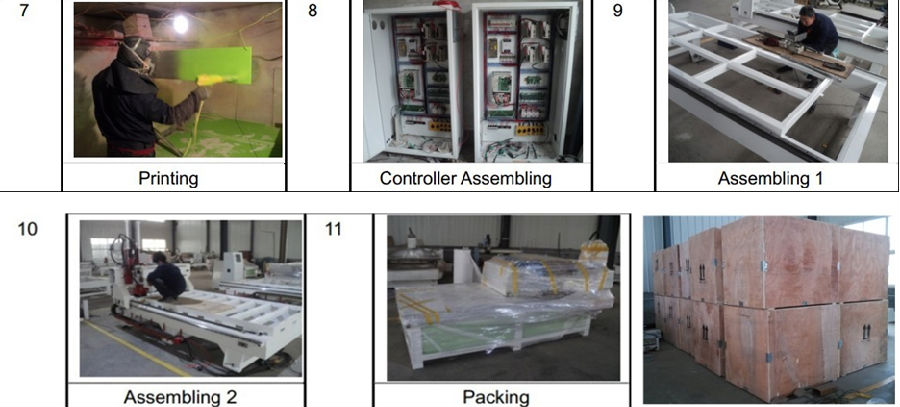

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q: Application of CNC woodworking engraving machine

- The use of CNC woodworking engraving machine in the woodworking industry, instrument industry, furniture decoration, wooden handicraft industry, a large area of plane plate engraving, wood furniture, mahogany furniture, wood art murals, MDF Mianqi door, composite door, window and door cabinets, bedside cabinets, screens carved etc.. Two in the mold industry, can carve all kinds of mold, wood, wooden propeller, aviation, automotive foam mould.

- Q: Woodworking engraving machine engraving 3D relief skills do you know?

- The woodworking engraving machine automatically generates sequences of varying shades of engraving. Woodworking engraving machine produced this effect gives a strong three-dimensional feeling. In general, this kind of sculpture is done by sharp knives. Sometimes, because the area between the two lines of the pattern is large or the strokes are rough, the so-called "isolated island" will be produced.

- Q: Which is the best woodworking engraving machine? Both at home and abroad!

- The preferred CNC woodworking engraving machine engraving machine, buy at home don't believe what the large manufacturers, manufacturers customer service sucks, always say no time, after a period of customer service charges are more scary, Shandong are now go abroad, why, domestic market dies, equipment quality too bad, afraid, now the engraving machine manufacturers in Shenzhen is good, the main customer service service.

- Q: Woodworking engraving machine how much money?

- Woodworking engraving machine is to pay attention to the wood processing, make it more beautiful. Woodworking engraving machine types currently on the market variety, the quality and the price is also uneven, therefore, when choosing woodworking engraving machine to select carefully, or put your needs to inform the staff Dewin engraving machine according to what you say they will request to choose the most suitable models for you.

- Q: CNC woodworking engraving machine can be processed?

- CNC woodworking engraving machine applies to:Advertising, acrylic, PVC, PP, ABS board, wood, wood and other non-metallic materials, three-dimensional processing, cutting, carving, engraving plane.

- Q: How can the path of woodworking engraving machine be changed step by step?

- When we have a relatively complex pattern or document to do a good tool path, but found that the size of the graphics and the actual proportion of the material has a certain gap. In this case, we can modify the path through the path change function of the woodworking engraving machine, thus saving the time for redesigning the graphics and re doing the path. The path transformation function can be used not only to change the path size, change the location of the path, but also to rotate the path in space.

- Q: What kind of knowledge do you need to master woodworking engraving machine?

- The use of cutting tools for CNC woodworking engraving machines:After theoretical training, CNC woodworking engraving machine tool training must be carried out. Operators can be familiar with tools, engraving motor speed, speed, attention, etc., must be clear, operators must be familiar with the application of cutting tools.

- Q: What is a multi process woodworking engraving machine?

- The processing center can be understood as an upgrade of multiple processes. A machine can carry more than 8 knives. Some processing centers, such as single arm machining centers, and even with sawing, cutting, planing, milling and other functions in one, the realization of a single machine to complete a variety of processes.

- Q: How to judge the temperature of the stepper motor of woodworking engraving machine overheating?

- Actually, the question is simple. Stepper motor heating reasonable scale, motor heating promised to what extent, mainly depends on the internal insulation level of the motor. Internal insulation can be damaged at high temperatures (above 130 degrees). Therefore, the motor does not damage if it does not exceed 130 degrees inside. We can't measure the internal temperature accurately, but we can measure the surface temperature of the motor. When the internal temperature is 130 degrees, the outside will be around 90 degrees. Therefore, the stepper motor surface temperature is normal at 70-80 degrees.

- Q: CNC woodworking engraving machine to do the flat door, how to lift the corner?

- This should be based on the size of your tool to set up 3D angle carved software can achieve this function

Send your message to us

Professional latest cnc engraving machine for woods

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords