Distributors Wanted MB -1410 Co2 CNC Laser Engraving Machine Eastern Price with Two Laser Heads

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

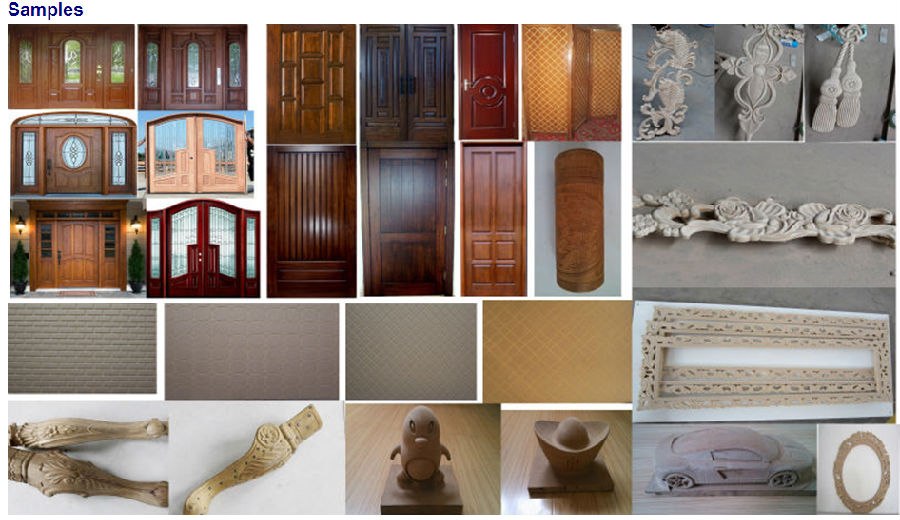

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q: What should I pay attention to when purchasing woodworking engraving machine?

- Engraving machines for delivery and trainingWhen the engraving machine arrives, it is usually carried out by technicians to check out the machine. After checking the electricity, the appearance is inspected carefully, and whether it is damaged or not during transportation is damaged. If it is in good condition, then check the contract with random instructions, machine configuration with random accessories. Installation of machines by technical personnel (including hardware installation, removal of fasteners, and placement of machines). Connect the power supply with various cables. Software installation, configuration of computer, installation of engraving software. After the installation, the engraving machine will be tested by Yan Yan or the customer's personal test file, such as completing the engraving test and checking the delivery. Customer operation personnel to computer operation skilled, in the training process should be mastered according to different quantity to select different engraving speed and the use of a different tool, which often requires the accumulation of experience, grasp the good, good to prolong the machine and the tool life was.

- Q: 325 woodworking engraving machine, engraving 50mm thick MDF, need how much of the spindle, the Z axis travel what are the requirements? What knife do you need?

- And the knives should be long enough. There are no requirements for the Z axis, and the travel time is above 80. Don't worry about this. Such as cutting density boards, wooden doors, screens, and so on, Longmen in custom when it is required to heighten, of course, as long as it does not affect the processing.

- Q: Can a woodworking engraving machine be the same as a relief machine?

- In fact, wood carving machine and embossing machine function principle is basically the same.

- Q: How to draw the carving patterns of woodworking engraving machines?

- Wen Tai three-dimensional engraving software, support the production of various computer engraving machine at home and abroadThe 3D engraving software combines the speed and the strength of the engraving machine with the accuracy, flexibility and reliability of the computerWen Tai three-dimensional engraving software, including the following functions:Badge engraving software: according to the characteristics of the development of the badge making, specifically for the badge card. Support only typesetting a chest style, the use of the software database typesetting function, you can immediately produce the same kind of different personnel, positions and other formats of the chest card.Professional cutting word software: according to the engraving machine processing words and graphics features, dedicated to cutting the word software. The user can according to the size of the first pre cutting material on a computer to be filled with words and graphics, and then use the engraving machine can be output, without considering the complex graphics, text strokes related sequence and engraving parameters.

- Q: How to realize arc plane with 1325 woodworking engraving machine

- If you want to cut this figure, the tool path menu has an outline cut, you can adjust the parameters inside, and then generate the path. Finally, output to the engraving machine inside.

- Q: What is the configuration of a single head woodworking machine?

- Single head woodworking engraving machine configuration:Type: Dewin 1325 optional: less than 2550 (2.5*5.0M)The: a fault avoidance rate of more than 0.2%1.5 years under normal useThe life of the machine is not less than 5 years note: healthy working environment, no major mistake

- Q: The best engraving machine, woodworking engraving machine, which is the best quality?

- Woodworking engraving machine friendship reminder: engraving machine is not omnipotent, engraving machine is not able to do all the work. Engraving machine manufacturers engraving machine is divided into various specifications, models, in order to deal with a variety of processing tasks. For example, you buy a mold level engraving machine to carve the swatches, or buy a large engraving machine to engrave the seals, which makes great waste, and won't get good results. Also, you buy an advertising engraving machine to make a mold, and you may not be able to do it at all. So before you purchase, you must show the sales staff clearly what you want to do, including the size of the workpiece, the material, the thickness of the material, the weight, the final engraving effect and requirements and so on.

- Q: The configuration of woodworking engraving machine

- General woodworking engraving machine with good point configuration, with a 450 40B motor, larese 860 driver, Taiwan Silver Genuine Weihong control, linear guide, can meet your requirements

- Q: How to draw a woodworking engraving machine?

- The graphics software CAD, CDR, Wen Tai, these software, our woodworking engraving machine are supported

- Q: What are the main points for copy classification in woodworking engraving machines?

- When using copy layering, the system first computes the last layer path, and then gets the path of the other layer by Z to the translation. It avoids the taper of the cone when it is layered, leaving the ladder at the side because the cone angle is inaccurate. Deepen the projection rough machining also use this function to improve the efficiency and the service life of ball cutter machining.

Send your message to us

Distributors Wanted MB -1410 Co2 CNC Laser Engraving Machine Eastern Price with Two Laser Heads

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords