Professional cnc engraving machine High quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNC Router For Woodworking

1.1300 x 2500 x 200 mm

2.Air Cooled Spindle

3.CE Certificate & OEM supported

1.SPECIFICATION

WORKING AREA | 1300 X 2500 X 200mm |

SPINDLE POWER | 6KW,AIR COOLED,6000-24000RPM/MIN |

DRIVE SYSTEM | STEPPER MOTOR AND DRIVERS ON X,Y,Z AXIS |

WORKING SPEED | Y AXIS 25M/MIN, X AXIS 25M,Z AXIS 20M/MIN |

CONTROL SYSTEM | NC STUDIO NUMERICAL CNC SYSTEM (ENGLISH LANGUAGE);DSP PROGRAM |

WORKING VOLTAGE | 220V /380V |

TABLE | PVC MATERIAL WITH VACUUM SYSTEM |

OVERALL DIMENSION | 3900 X 2100 X 2100MM |

NET WEIGHT | 1200KGS |

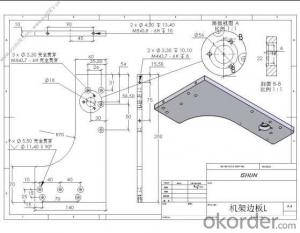

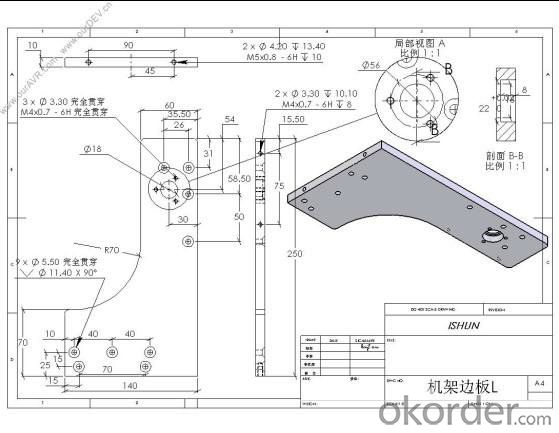

2. DETAIL PARTS INTRODUCTION

a). CONTROL CABINET BOARD

b). PRECISION RAIL GUIDE AND RACKS FOR TRANSMISSION (X&Y AXIS TRANSMISSION)

c). CONTROL CABINET d).OIL PUMPS FOR LUBRICATION

e). LEAD BALL SCRE (Z AXIS TRANSMISSION)

3. OTHER TERMS FOR MACHINERY

SINGLE PACKAGE: WOOD PALLET OR WOODEN CASE (OPTIONAL)

DELIVERY TIME: AFTER CONFIRMATION THE ORDER 35 DAYS

LOADING PORT: QINGDAO PORT, SHANDONG PROVINCE

- Q: CNC woodworking engraving machine what brand is good?

- Woodworking engraving machine will produce a lot of dust when working, engraving machine should be designed with a good dust suction device.

- Q: What skills do woodworking engraving machines require for carving path attribute switching settings?

- CNC woodworking engraving machine control system, which has a "path attribute switch" set the command, many beginners do not understand the specific meaning. The setting is mainly used to control whether or not the engraving path comes with machining parameters. These processing parameters include feed speed, spindle speed, slow down cutter distance, rapid tool height, and tool fall delay time.

- Q: Woodworking engraving machine how to achieve hierarchical carving?

- Choose woodworking engraving machine, tool path. Select the "wood", and the selection of woodworking engraving machine tool, here we must pay special attention to, in the tool edit parameters there is a "cutting down step", this value is the each layer under the knife distance, according to the quality of the hardness of the material and tool set.

- Q: What are the advantages and scope of CNC woodworking engraving machine?

- CNC woodworking engraving machine for wooden doors, cabinet doors, solid wood doors, doors, wooden craft relief carving, engraving, carving and milling machine, engraving speed, high precision, large bearing and long service life. CNC woodworking engraving machine is wood industry, the cabinet industry, furniture industry and other industries required equipment.

- Q: How to draw the carving patterns of woodworking engraving machines?

- According to the different needs of engraving users, the company's current 3D engraving software covers all the functions of 2D engraving software. Two dimensional engraving function is mainly used in plane work, such as double color swatches, chest cards, signs, gift decorations and other industries. Three dimensional engraving software can meet the needs of processing and producing all kinds of 2D and 3D engraving products. Such as acrylic three-dimensional signs, industrial dial, and other giant signs, logo and so on.

- Q: Woodworking engraving machine prices?

- Choose wooden door engraving machine, the price is only on the one hand, engraving machine performance, manufacturers after-sales service is very important

- Q: What U dish does the woodpecker use?

- Yes, it can be the U disk. It's not in the right format. You can reformat it.

- Q: What kind of knowledge do you need to master woodworking engraving machine?

- The use of cutting tools for CNC woodworking engraving machines:After theoretical training, CNC woodworking engraving machine tool training must be carried out. Operators can be familiar with tools, engraving motor speed, speed, attention, etc., must be clear, operators must be familiar with the application of cutting tools.

- Q: 5.5kW spindle woodworking engraving machine can be replaced with 4.5kw spindle?

- If it's water cool, too, but extra water will be needed. Because the water-cooled spindle is water cooled.

- Q: The difference between a woodworking engraving machine and an advertising engraving machine

- From the exterior view are similar, but the advertising machine can only do advertising engraving, and woodworking engraving machine not only can do a good wood engraving work well, advertising engraving, woodworking engraving machine in a nutshell is better than advertising engraving machine, of course, the price is high.

Send your message to us

Professional cnc engraving machine High quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords