High Quality Wood Engraving Machine CNC Router

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNC Router For Woodworking

1.1300 x 2500 x 200 mm

2.Air Cooled Spindle

3.CE Certificate & OEM supported

1.SPECIFICATION

WORKING AREA | 1300 X 2500 X 200mm |

SPINDLE POWER | 6KW,AIR COOLED,6000-24000RPM/MIN |

DRIVE SYSTEM | STEPPER MOTOR AND DRIVERS ON X,Y,Z AXIS |

WORKING SPEED | Y AXIS 25M/MIN, X AXIS 25M,Z AXIS 20M/MIN |

CONTROL SYSTEM | NC STUDIO NUMERICAL CNC SYSTEM (ENGLISH LANGUAGE);DSP PROGRAM |

WORKING VOLTAGE | 220V /380V |

TABLE | PVC MATERIAL WITH VACUUM SYSTEM |

OVERALL DIMENSION | 3900 X 2100 X 2100MM |

NET WEIGHT | 1200KGS |

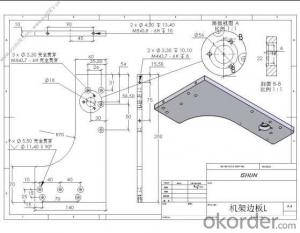

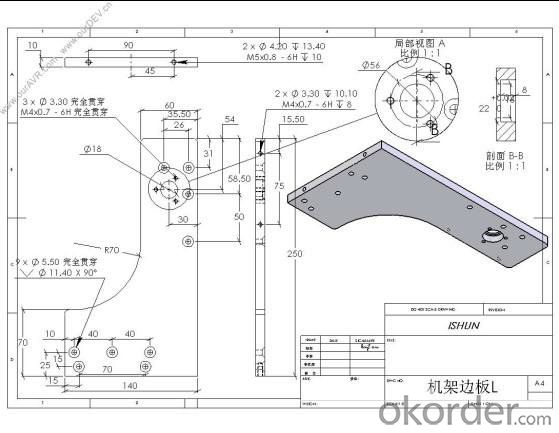

2. DETAIL PARTS INTRODUCTION

a). CONTROL CABINET BOARD

b). PRECISION RAIL GUIDE AND RACKS FOR TRANSMISSION (X&Y AXIS TRANSMISSION)

c). CONTROL CABINET d).OIL PUMPS FOR LUBRICATION

e). LEAD BALL SCRE (Z AXIS TRANSMISSION)

3. OTHER TERMS FOR MACHINERY

SINGLE PACKAGE: WOOD PALLET OR WOODEN CASE (OPTIONAL)

DELIVERY TIME: AFTER CONFIRMATION THE ORDER 35 DAYS

LOADING PORT: QINGDAO PORT, SHANDONG PROVINCE

- Q: Woodworking engraving machine can be used to do what?

- Applicable scope: woodworking industry: all kinds of doors, windows, cabinets, wooden doors, paint free door, screen, craft window, wave board processing, all kinds of furniture, wood processing. Advertising industry: advertising signs, marking production, advertising materials cutting, plastic molding, LED neon production and other materials, advertising decorative products.

- Q: How much money a small engraving machine

- Engraving machine prices are based on the engraving machine configuration and size of the machine to decide.

- Q: What is the difference between a woodworking engraving machine and a computer operating system and a handle control system?

- Woodworking engraving machine handle control system advantage is to save space, and uses computer; drawback is relative to the operation of some trouble, after all, are all set in a control panel, the operation is not very easy to press the wrong button.Woodworking engraving machine computer control system has the advantages of processing can preview the effect, you can always see the processing path, if the program loading errors can be corrected timely; drawback is that requires a computer, increase the cost of production.

- Q: What is the cause of noise in vacuum pumps for woodworking engraving machines?

- First check whether there is high pressure blower in debris, such as, open the shell, internal cleaning; secondly, check the impeller is stuck, it is best to contact the high pressure blower factory repair, re assembly to eliminate the fault. Third check the bearings for damage and replace the bearings if necessary.

- Q: Woodworking engraving machine can be engraved on the drums?

- Woodworking engraving machine can be engraved on the drum, as long as the wooden drums can.

- Q: How to distinguish the cutter type of woodworking engraving machine?

- The tool size should be correct, the geometric parameters of the tool should meet the requirements of material processing, and the size and angle are correct

- Q: 1325 how much is woodworking engraving machine?

- Main shaft, water cooling and air cooling. The price of air-cooled with the same power is more expensive than that of water-cooledOf course, there are other wires, ah, ah ah the whole machine, vacuum adsorption and so on, so the price is to find manufacturers more detailed understanding of what kind of equipment, which configuration is the most suitable for their own. Not to buy expensive, but to buy the most suitable for their products.

- Q: Which woodworking engraving machine brand is good?

- Woodworking engraving machine is to pay attention to the wood processing, make it more beautiful. Woodworking engraving machine types currently on the market variety, the quality and the price is also uneven, therefore, when choosing woodworking engraving machine to select carefully, or put your needs to inform the staff Dewin engraving machine according to what you say they will request to choose the most suitable models for you.

- Q: Dry CNC woodworking carving okay?

- CNC woodworking engraving machine tool use: after theoretical training, CNC woodworking engraving machine tool training must be carried out. Operators can be familiar with tools, engraving motor speed, speed, attention, etc., must be clear, operators must be familiar with the application of cutting tools.

- Q: Which brand of engraving machine is good, mainly carpentry?

- Attention should be paid to its rail. Large format engraving machine must adopt widened import square guide rail, its load capacity and precision retention ability is round type guide rail more than 30 times, guarantee the engraving machine of high quality and high speed

Send your message to us

High Quality Wood Engraving Machine CNC Router

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords