Printed Prepainted Galvanized Steel Coils for Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

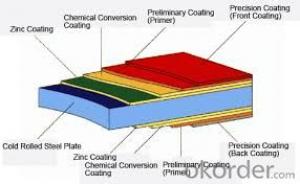

1. AZ zinc coil PPGI PPGL GI GL

2. Size: 0.13-1.2X600-1250mm

3. Zinc: 60-275g

4. Competitive price

We produce and supply various kinds of steel coils, steel strips. Free sample can be provided. Welcome to contact for further information.

| NAME | ppgi color coated galvanized steel coil | GALVANIZED | GALVALUME/ALUZINC |

| CERTIFICATE | ISO9001 | ||

| STANDARD | GB/T-12754 JIS G 3312 EN 10169 ASTM A755 | GB/T-2518 JIS G 3302 EN 10142/10427 ASTM A653 | GB/T-14798 JIS G 3321 EN 10215 ASTM A792 |

| GRADE | SGCC DX51D+Z DX53D+Z SGCH CGCD1-CGCD3 CGC340-CGC570 | SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D+Z DX53D+Z | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

| MODEL NO | 0.13MM -1.2MM *600-1250MM | (0.12-1.5)*600-1250MM | 0.16MM -1.5MM *600-1250MM |

| ZINC OR AZ Coating | 60-275g/m2 | 60-275g/m2 | 60-150g/m2 |

| Painting | top paint 16-25um back paint 7-10 | ||

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc |

| SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating | |

| APPLICATION | Structural use ,roofing, corrugated roofing, commercial use, household appliance, industry, family | ||

| SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: How are steel coils used in the manufacturing of oil and gas equipment?

- Steel coils are commonly used in the manufacturing of oil and gas equipment due to their durability and strength. They are typically formed into various shapes and sizes to create components such as pipes, tanks, valves, and fittings. These coils are processed and fabricated into these equipment to withstand the demanding conditions of the oil and gas industry, including high pressures, corrosive environments, and extreme temperatures.

- Q: How do steel coils contribute to durability and longevity in products?

- The durability and longevity of products are greatly enhanced by steel coils, mainly because of their strength, stability, and resistance to corrosion. Firstly, steel is widely known for its exceptional strength, making it the perfect material for applications where durability is crucial. Steel coils, which are essentially tightly rolled steel, add strength and structural integrity to products. The stability offered by steel coils is another important factor in improving product durability. The tightly rolled structure of the coils ensures that they maintain their shape and resist deformation even under heavy loads or extreme conditions. This stability is particularly significant in industries like construction and automotive, where products need to withstand rigorous usage for long periods of time. Furthermore, steel coils have excellent resistance to corrosion, primarily due to the presence of protective coatings. These coatings, such as zinc or other metallic alloys, act as a barrier against moisture and environmental elements that cause rust and degradation. By preventing corrosion, steel coils help extend the lifespan of products, making them more durable and reliable. Moreover, steel coils can be customized to meet specific requirements, such as different thicknesses, widths, or surface finishes. This versatility allows manufacturers to tailor the steel coils to their desired application, ensuring optimal performance and longevity in their products. To sum up, steel coils contribute to the durability and longevity of products through their strength, stability, corrosion resistance, and customization capabilities. By incorporating steel coils into various industries and applications, manufacturers can ensure that their products last longer and provide greater reliability to consumers.

- Q: How does the steel coil market vary regionally?

- The steel coil market varies regionally based on factors such as demand, production capacity, and market dynamics. Different regions have different levels of industrial development and infrastructure, which can affect the demand for steel coils. Additionally, variations in raw material availability, labor costs, and government policies also contribute to regional differences in the steel coil market. For example, developing regions may have higher demand for steel coils due to infrastructure projects, while mature markets may focus on specialized steel coil products for specific industries. Overall, regional variations in the steel coil market reflect the unique economic and industrial characteristics of each region.

- Q: Can steel and/or stainless steel turn rusty ?

- Stainless is an alloy mixture the contains iron and nickel and does not rust.

- Q: What are the different packaging options for steel coils?

- The different packaging options for steel coils include wooden crates, steel frames, and coil covers.

- Q: How are steel coils inspected for edge quality?

- Steel coils are inspected for edge quality through visual examination, measuring thickness and width, and conducting various tests such as bend tests and surface inspections.

- Q: Apparently, this has to do something with electrochemical cells.

- Steel wood? I don't think there is such a thing?

- Q: How are steel coils processed for edge trimming or shearing?

- Steel coils are processed for edge trimming or shearing by first uncoiling the coil and feeding it into a machine equipped with either rotary shears or slitting knives. These tools trim or shear the edges of the coil to remove any irregularities, ensuring a precise and uniform width. The trimmed edges are then inspected for quality and smoothness before the coil is recoiled for further processing or storage.

- Q: I'm trying to make a corset but I can't find any steel boning in my area. Any clue as to what materials I could buy to to make my own bones, or anything that would work similarly?I know there are places to buy it online, but the cost of shipping makes it barely seem worth it.

- Hi, buy the original bones. They are designed to corset's load. If you use any substitute material it could break and it could be cause of injuries. Use google for link to corset's bones suppliers. Look on:

Send your message to us

Printed Prepainted Galvanized Steel Coils for Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords