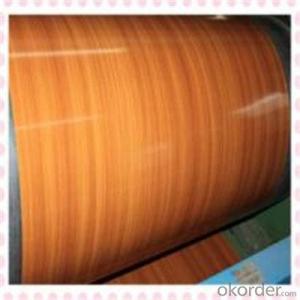

PRINGTING STEEL---WOODEN PATTERN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pattern Printed Coil Steel

Product Description :

Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Thickness | 0.16mm-0.7mm |

Width | 1250mm or under |

Tolerance | thickness+/-0.01mm |

Surface treatment | galvanized / galvalumized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

Anti-MEK Wiping | ≥100times |

Zinc coating | 40-180g |

Type of coating structure | 2/1 or 2/2 coating, or customized |

Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

Color | customized |

Application | Building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

- Q: How do steel coils compare to other materials in terms of strength?

- Steel coils are renowned for their remarkable strength and durability, rendering them among the most robust materials obtainable in the market. In comparison to alternative materials like aluminum or plastic, steel coils demonstrate unparalleled strength and resilience against deformation or breakage. Due to the elevated tensile strength of steel, coils can withstand substantial loads, thereby rendering them perfect for diverse industrial uses, encompassing construction, automotive manufacturing, and the production of heavy machinery. Moreover, steel coils possess exceptional fatigue resistance, enabling them to endure repetitive stress and strain without compromising their structural integrity. This strength advantage positions steel coils as the preferred choice for applications that prioritize reliability and safety.

- Q: basically a builder told us steel is good but when we got MFI, BQ they only have acrylic

- I okorder . There are so many articles on this site that talk about all of the bathtubs available today. If you're wondering about what kind of material is best for a bathtub, this site will definitely help!

- Q: How are steel coils used in the production of metal furniture?

- Steel coils are used in the production of metal furniture as they are the primary raw material for manufacturing various components such as frames, legs, supports, and brackets. These coils are unrolled and passed through different machinery to shape and cut them into the desired sizes and shapes. The resulting pieces are then welded, joined, or assembled to create the different parts of the furniture. The strength and durability of steel make it an ideal material choice for metal furniture, ensuring sturdy and long-lasting products.

- Q: What are the safety regulations for handling steel coils?

- The safety regulations for handling steel coils typically include wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots. Additionally, workers are often required to receive proper training on safe lifting techniques and use of equipment, as well as understanding the weight and dimensions of the coils being handled. It is important to ensure a clear and organized work area, secure stacking and storage practices, and the use of appropriate lifting equipment, such as cranes or forklifts, to minimize the risk of accidents, injuries, and damage to the coils or surrounding infrastructure.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or indented patterns on a surface, and it can be done on various materials including steel coils. This technique is often used to enhance the aesthetic appeal or provide functional properties to the steel coils.

- Q: Can steel coils be stamped?

- Yes, steel coils can be stamped. Stamping is a common manufacturing process used to shape and cut steel coils into desired forms and designs.

- Q: Moravia’s coal and steel industries face challenges because they _____. a.do not run efficientlyb.have run out of resourcesc.have a declining work forced.have not privatized

- do not run efficiently is the correct answer

- Q: I have a set of steel pans with copper bottoms. When I cook with oil it always burns the oil to the pan and takes days to clean. I don't think I should use steel wool, since it might scratch the surface. Does anyone know a faster way to clean scorched oil off a steel pan?

- Get a can of Barkeeper's Friend. It's a powdered cleanser. It's gentle enough to be used on a ceramic cook top but still strong enough to get metal clean. Cheap and made from rhubarb leaves! Dampen the pan with water, sprinkle generously and smear around with a sponge with one of those non-stick safe nylon scrub pads. Wait about 10-15 minutes to let the product do some of the work for you. Come back and give it a good scrub. Reapply if necessary. I have all stainless steel cookware and use the Barkeeper's to keep them looking nice; especially since they are on display with my pot rack. I also have some copper pieces used for decoration and I use the Barkeeper's to keep them looking nice. It cleans them up faster and better than any of the homemade concoctions or metal cleaners without the residue. And I do use it on my ceramic cook top too! Be sure to wash and rinse the pan after you get it clean; it does leave a haze if you don't.

- Q: i want to buy an exhaust but whats the difference between satinless steel and titanium exhaust?

- Stainless steel is more corrosion resistant than steel and titanium is more corrosion resitant and lighter. However, titanium is more prone to picking up (scratches caused by normal tools creating scratches and leading to stress fractures). The Lockheed Blackbird had to have tools treated lithium grease (i could be wrong) to prevent this. I'd stick with stainless steel as i think any titanium exhaust you can buy will be a titanium composite due to its cost

- Q: okay i got some questions of the steel plow.1st - who inveneted it? where and when?2nd - how did it work? what is it used for? what is it made of? how is it produced?okay guys thank you very much. remember best answer gets best answer 10 points!

- You want ot read up on American John Deere; he madethe first plow capable of cutting the virgin sod of the great planes.

Send your message to us

PRINGTING STEEL---WOODEN PATTERN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords