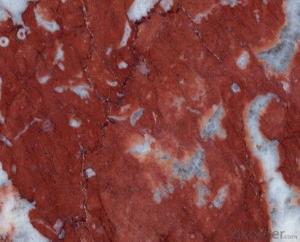

PRINGTING STEEL---MARBLE PATTERN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,GB,JIS | Grade: | SGCC | Thickness: | 0.2mm-1.2mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | EAST STEEL | Type: | Steel Coil |

| Technique: | Cold Rolled | Surface Treatment: | Coated | Application: | Other |

| Special Use: | Wear Resistant Steel | Width: | 800mm-16000mm | Length: | as customer's required |

Specifications

1) Manufacturer of Galvanized Steel Coil

2) Superior quality with moderate price

3) Wide size range

4) Quick delivery

items | thickness | TYPE | Features |

Protection film | 50μm | polyethylene | Protecting from scratchs and contamination (Option) |

Finished coat | 10μm | PVDF | Protecting printed layer and enhances the appearance of the surfaces |

1μm | Ink, Polyester | Various printing patterns,3 color overprint | |

Top coat | 20μm | Polyester Fluorine | Chemical resistance, formability and patterns multiformity |

Primer coat | 5μm | Polyester | workability, corrosion resistance and adhesion to the primer coating |

Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

substrate | 0.2-1.2mm | GI.GL.AL | GI.GL,AL |

Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

Back coat | 5μm | Epoxy | corrosion resistance and adhesion to the substrate |

- Q: i have a sword and some knives that have this grade steel. so is it a high grade or low grade? and how can i tell the differance between a high grade and a low grade?

- Type 440—a higher grade of cutlery steel, with more carbon in it, which allows for much better edge retention when the steel is heat treated properly. It can be hardened to Rockwell 58 hardness, making it one of the hardest stainless steels. Also known as razor blade steel. Available in three grades 440A, 440B, 440C (more common) and 440F (free machinable).

- Q: How are steel coils inspected for impact resistance using impact testers?

- To assess the impact resistance of steel coils, specialized machines called impact testers are utilized. These machines are designed to evaluate the coils' ability to endure impacts. The process involves subjecting the coils to controlled impacts and measuring the resulting deformation or damage. Initially, the steel coils are securely positioned and oriented on the impact tester. This ensures accuracy and consistency. The tester is equipped with a striking element, like a pendulum or falling weight, which applies a specific force upon impact. The element is aligned precisely with the steel coil for precise testing. Once the setup is complete, the impact tester is activated, and the striking element is released to impact the steel coil. The force of the impact is carefully controlled and measured to ensure consistency across multiple tests. The tester records various parameters, including applied force and impact duration. After the impact, the steel coil undergoes a thorough examination for visible deformation or damage. This includes checking for dents, cracks, or any signs of structural compromise. The extent of the deformation or damage is recorded and compared to predetermined acceptance criteria to determine if the coil passes or fails the impact resistance test. To gather additional data during testing, impact testers can be equipped with various sensors and cameras. High-speed cameras capture the impact in slow motion, allowing for detailed analysis of the coil's behavior. Strain gauges can also be attached to the steel coil to measure strain and stress experienced during the impact. In conclusion, the use of impact testers offers a reliable and standardized method for inspecting the impact resistance of steel coils. By subjecting the coils to controlled impacts and accurately measuring deformation or damage, manufacturers can ensure that their steel coils meet the required impact resistance standards for different applications.

- Q: How are steel coils used in the manufacturing of metal containers?

- Steel coils are used in the manufacturing of metal containers as they are processed into flat sheets or strips, which are then cut, formed, and welded to create the desired shape and size of the container. The coils provide a strong and durable material that can withstand the pressure and weight of the contents inside the container, ensuring its structural integrity and longevity.

- Q: Can steel coils be coated with anti-fingerprint materials?

- Yes, steel coils can be coated with anti-fingerprint materials. These coatings are designed to reduce the visibility of fingerprints and smudges, making the steel coils more resistant to marks and easier to clean.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide strength and durability to the ducts. These coils are shaped and formed into the desired ductwork design, providing a rigid structure that can withstand the pressure and movement of air. The steel coils also ensure that the ductwork maintains its shape over time, preventing any deformation or collapse.

- Q: my step father bought a big steel drum grill it has steel sheets (very thin) that go inbetween the flame and the food (closer to the flame) with that there the food will not cook, it does not get hot enough????? please help... what should we do

- yes that keeps the fat from dripping on the burners - just try it - it works.

- Q: How are steel coils used in the production of agricultural storage tanks?

- Steel coils are used in the production of agricultural storage tanks as they are shaped and welded together to create the tank's structure. The coils provide strength and durability to ensure the tank can withstand the weight and pressure of the stored materials.

- Q: I'm pretty sure that this topic has been beaten to death by now. But, I still can't get a definite answer. With stainless steel, you get better corrosion resistance, and you will hold and edge longer. With carbon steel, you will hold a sharper edge, and you could forge a knife blade longer than 2 ft without breakage. I'm personally a fan of stainless steel ( the 440 grade stuff ), just because it seems to hold up to use and abuse better in the long run. HOWEVER, I have NEVER had a factory made knife break on me. I don't think that they would try to sell you a knife that didn't do what it was meant to do, at least to a reasonable degree. (I work for a living, and can't afford a custom $600 knife.) What do you think? Is this a pointless topic? Will there ever be a winner?

- I hate stainless steel! I hate shiny blades also! When I was a kid knifes were awesome! You could actually sharpen them! :) If we bought a new knife we would take an orange and slice it and leave the juice on the blade to purposefully darken it. If you had a shiny blade that looked like stainless you were not cool. :) I think most anyone who had an old knife from back in the 70's or before would agree that these new stainless knives are crap. I have not seen anything perform close to the old blades in stainless. Today I bought a case CV Sod Buster hoping it will perform like the old knives. What reading I have done the Chrome Vanadium is supposed to be like the old steel. I sure hope it is. Now to find some fruit to get rid of this annoying shiny blade! :)

- Q: What are the common methods of protecting steel coils from corrosion during storage?

- To safeguard steel coils from corrosion during storage, there are multiple commonly employed techniques. These methods aim to shield the steel coils from moisture and other environmental factors that could trigger corrosion. 1. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging is extensively utilized for steel coil protection. It incorporates VCI materials into the packaging, such as plastic bags or films. These materials emit a vapor that forms a protective layer on the surface of the steel coils, effectively preventing the intrusion of moisture and corrosive agents. 2. Oil Coating: Another widely adopted approach involves applying a thin layer of oil onto the steel coil surface. This oil acts as a barrier, obstructing the contact between the steel and moisture or oxygen. It proves particularly effective for long-term storage or transportation situations. 3. Desiccants: Silica gel packets or similar desiccants can be placed inside the packaging to absorb any trapped moisture. By reducing humidity levels within the packaging, the risk of corrosion is minimized. This method is often combined with VCI packaging or oil coating. 4. Proper Ventilation: Adequate ventilation is crucial to prevent moisture buildup around the steel coils during storage. By facilitating the free circulation of air, humidity levels are reduced, and the formation of condensation, which can lead to corrosion, is prevented. 5. Controlled Environment: Storing steel coils in a controlled environment is an effective corrosion prevention measure. This entails maintaining constant temperature and humidity levels that are unfavorable for corrosion. Temperature and humidity control can be achieved using air conditioning or dehumidification systems. It should be noted that the choice of specific protection methods or combinations thereof depends on various factors, including storage duration, environmental conditions, and specific steel coil requirements. Regular inspections and maintenance are also vital to ensure ongoing corrosion protection.

- Q: They say it's some six times stronger than steel. need some explanation.

- Most importantly, spider silk is extremely lightweight: a strand of spider silk long enough to circle the Earth would weigh less than 500 grams (18 oz). Spider silk is also especially ductile, able to stretch up to 140% of its length without breaking. It can hold its strength below ?40 °C. This gives it a very high toughness (or work to fracture), which equals that of commercial polyaramid (aromatic nylon) filaments, which themselves are benchmarks of modern polymer fiber technology. What this means in regard to what you have heard is that if you compared the tensile strength (type 'tensile strength' on wikipedia if you do not know what it means) of spider silk and a strand of steel at the same thickness, the silk would have a higher tensile strength than many grades of steel, upto that of high grade steel - of which they are about the same.

Send your message to us

PRINGTING STEEL---MARBLE PATTERN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords