Prime Hot Rolled Carbon Steel Plate_Sheet dimensions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

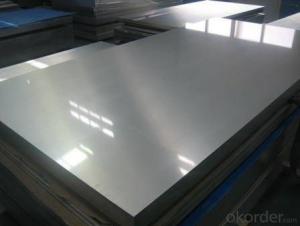

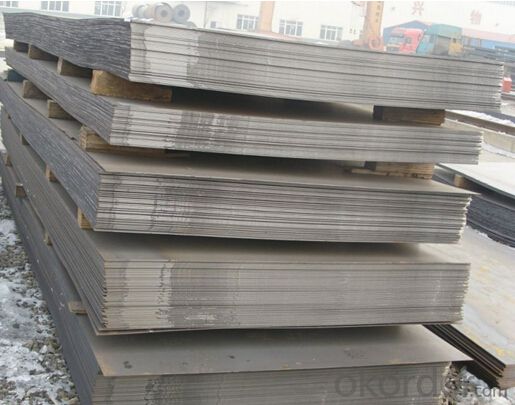

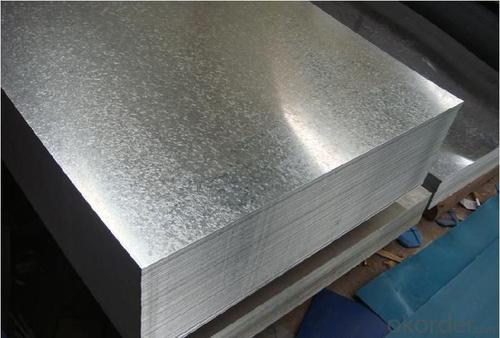

Prime Hot Rolled Carbon Steel Plate_Sheet Dimensions

Thickness:0.6-200mm

Width:1000-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

Specification of Hot Rolled Carbon Steel Plate_Sheet

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045,Q195,Q235,Q345,SS400,ASTM A36,E235B mild steel plate |

Usage | the mild steel plate will used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of the Hot Rolled Carbon Steel Plate_Sheet Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of the Hot Rolled Carbon Steel Plate_Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Does special steel require special machining techniques?

- Yes, special steel does require special machining techniques. Special steel, also known as tool steel or high-performance steel, has unique properties such as high hardness, wear resistance, and toughness. These properties make it more challenging to machine compared to regular or mild steel. Special machining techniques such as high-speed machining, cutting tool selection, and cooling methods are often required to achieve precise and efficient machining results with special steel.

- Q: How is special steel used in the production of engine components?

- Special steel is used in the production of engine components due to its high strength, durability, and resistance to heat and corrosion. It is commonly used for manufacturing pistons, crankshafts, valves, and connecting rods, ensuring the engine's optimal performance and longevity. Additionally, special steel's ability to withstand extreme temperatures and stress makes it an ideal choice for critical engine parts, enabling them to function efficiently under demanding conditions.

- Q: What are the main applications of special steel in the mining exploration?

- Special steel has various crucial applications in mining exploration. One main application is in the construction of drilling equipment, such as drill bits and drill rods, which require high strength and durability to withstand the challenging conditions of drilling in hard rock formations. Another important use of special steel in mining exploration is in the manufacturing of conveyor belts and other material handling systems, which need to be resistant to abrasion and corrosion. Additionally, special steel is employed for the fabrication of mining machinery components like gears, shafts, and valves, ensuring reliable performance and longevity under extreme operating conditions.

- Q: What are the main applications of special steel in the automotive electrical systems?

- Special steel is commonly used in automotive electrical systems for various applications, including the production of electrical connectors, terminals, and other components. These materials offer excellent conductivity, corrosion resistance, and high temperature stability, ensuring reliable and efficient performance in demanding environments. Additionally, special steel can be used in the manufacturing of sensors, switches, and relays, providing durability, precision, and enhanced safety features in automotive electrical systems.

- Q: What are the main advantages of using special steel in the automotive industry?

- Special steel has several main advantages in the automotive industry. Firstly, it offers increased strength and durability, allowing for lighter weight components without compromising safety. This not only improves fuel efficiency but also enhances overall vehicle performance. Secondly, special steel has excellent corrosion resistance, ensuring a longer lifespan and reducing maintenance costs. Lastly, its versatility enables the production of complex shapes and designs, enabling manufacturers to create innovative and efficient automotive structures.

- Q: How is special steel used in the power generation industry?

- Special steel is used in the power generation industry for various applications such as turbine blades, generator rotors, and boiler components. These steels possess exceptional strength, corrosion resistance, and heat resistance properties, making them suitable for withstanding high temperatures and pressures in power plants. They help improve the efficiency and reliability of power generation equipment, ensuring safe and uninterrupted electricity production.

- Q: How is mold steel used in the production of plastic injection molds?

- Mold steel is used in the production of plastic injection molds as it provides the necessary hardness, durability, and heat resistance required for the molding process. It ensures the molds can withstand the high pressures and temperatures involved in plastic injection molding, allowing for the precise and efficient production of plastic parts.

- Q: How does the hardness of special steel affect its machinability?

- The hardness of special steel has a significant impact on its machinability. In general, as the hardness of the steel increases, its machinability decreases. Machinability refers to the ease with which a material can be machined or shaped using various machining processes such as cutting, drilling, or milling. Hardness is a measure of a material's resistance to indentation or scratching. It is typically measured using the Rockwell hardness scale or the Brinell hardness test. Special steel, which is known for its high strength and durability, often has a higher hardness compared to other types of steel. When machining special steel, a harder material poses challenges for several reasons. Firstly, harder materials are more difficult to cut, as they require higher cutting forces and generate more heat during the machining process. This can lead to increased tool wear and shorter tool life, resulting in higher production costs. Secondly, hard steel tends to have lower ductility and toughness, making it more prone to cracking or chipping during machining. This can lead to poor surface finish, dimensional inaccuracies, and even component failure. Moreover, the increased hardness of special steel also affects chip formation. Harder materials tend to produce shorter and more segmented chips, which can cause issues with chip evacuation and tool clogging. This can further hinder the machining process and affect the overall productivity. To improve the machinability of hard special steel, various strategies can be employed. The selection of appropriate cutting tools with specific geometries and coatings designed for hard materials is crucial. Additionally, optimizing cutting parameters such as cutting speed, feed rate, and depth of cut can help reduce the negative effects of hardness on machinability. In conclusion, the hardness of special steel has a direct impact on its machinability. As the hardness increases, the machinability decreases due to increased cutting forces, higher tool wear, reduced ductility, and chip formation challenges. However, with proper tool selection and optimization of cutting parameters, the machinability of hard special steel can be improved, enabling efficient and cost-effective machining processes.

- Q: How does special steel contribute to the power transmission sector?

- Special steel plays a crucial role in the power transmission sector by offering enhanced strength, durability, and corrosion resistance. It is used to manufacture various components like gears, shafts, bearings, and turbines, which are essential for transmitting power efficiently and reliably. The exceptional properties of special steel ensure that these components can withstand high loads, extreme temperatures, and harsh operating conditions, thus contributing to the overall efficiency and reliability of power transmission systems.

- Q: What are the different corrosion-resistant special steel alloys?

- Some examples of corrosion-resistant special steel alloys include stainless steel, which contains chromium and nickel for improved resistance to corrosion; duplex stainless steel, which has a combination of austenite and ferrite structures for enhanced corrosion resistance; and super duplex stainless steel, which has even higher levels of chromium, molybdenum, and nitrogen for superior corrosion resistance in harsh environments. Other corrosion-resistant alloys may include nickel-based alloys, titanium alloys, and aluminum alloys.

Send your message to us

Prime Hot Rolled Carbon Steel Plate_Sheet dimensions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords