Prime Hot Dipped Aluzinc Steel Sheet In Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Hot Dipped Aluzinc Steel Sheet In Coils

1.Structure of Prime Hot Dipped Aluzinc Steel Sheet In Coils

Prime Hot Dipped Aluzinc Steel Sheet In Coils is one kinds of building material on construction.Steel sheet in melting zinc trough, the sticking of a layer of zinc sheet. At present mainly adopts continuous galvanizing process, namely the continuous roll of steel plate in the melt zinc plating tank made of galvanized steel sheet; Alloying of galvanized steel. This kind of steel plate is made by hot dip method, but after the slot, immediately heated to a temperature of about 500 ℃, it make the generation of zinc and iron alloy membrane. This kind of galvanized volumes with good coating of the sex and weldability.

2.Main Features of Prime Hot Dipped Aluzinc Steel Sheet In Coils.

1) Rust-proof

2) Water-proof

3)Durable using

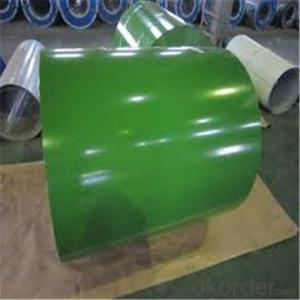

3. Prime Hot Dipped Aluzinc Steel Sheet In Coils Images

4. Prime Hot Dipped Aluzinc Steel Sheet In Coils Specification

1)Based raw material: Hot rolled steel coils or Cold rolled steel coils

2) Thickness

3) Width

4)Coating mass

5) Spangle

6)Surface treatment

7)Coil inner diameter

8)Painting kind

9)Painting color

10)Painting thickness

5.FAQ of Prime Hot Dipped Aluzinc Steel Sheet In Coils

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How is the packaging and delivery?

Exporting Package with the steel material cover and the delivery term is based on the project.

- Q: What is the (balanced) chemical equation for steel?

- This Site Might Help You. RE: Chemical equation for steel? What is the (balanced) chemical equation for steel?

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils include the quality and consistency of the incoming raw material, the precision of the rolling process, the tension applied during rolling, the cooling and annealing processes, and the handling and storage of the finished coils.

- Q: Can steel coils be used in the food processing industry?

- Yes, steel coils can be used in the food processing industry. Steel coils are often used to manufacture a wide range of food processing equipment such as conveyor belts, food storage tanks, mixing tanks, and processing machinery. Steel is a durable and hygienic material that is resistant to corrosion, making it suitable for use in food processing environments. Additionally, steel coils can be easily cleaned and sanitized, ensuring the safety and cleanliness of the food processing equipment. Overall, steel coils are a commonly used material in the food processing industry due to their strength, durability, and compatibility with food safety standards.

- Q: Is there a type of spray paint that would work on Stainless steel?That would also be permenant or at least make it through a wash or two?

- I've also learned something today! Good luck and have fun!

- Q: I just got the game Red Steel for the Wii. I want to use the sword in multiplayer mode, but I can't find it. Is it only for single player?

- Dude i hate to break it to you but its only single player, and if your talking about the first Red Steel, you can only use the sword in special moments in the game or showdowns i think that's what its called, but i play Red Steel 2, and its a better game, and you can use the sword anytime you want to, but again no online play, but it would be kinda nice to have it, just a thought!!! LoL Hope that helps....

- Q: How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in the production of shipbuilding materials as they are typically cut and shaped into plates, sheets, or beams that are then used to construct various components of a ship's structure such as the hull, decks, and bulkheads. The coils provide a reliable and durable base material that can withstand the harsh marine environment and ensure the structural integrity and strength of the ship.

- Q: How are steel coils used in the production of steel brackets?

- Steel coils are used in the production of steel brackets as they serve as the primary raw material. The coils are processed through various manufacturing techniques such as cutting, bending, and welding to shape and form the brackets. The high strength and durability of steel coils ensure that the brackets maintain their structural integrity and can withstand heavy loads or harsh conditions.

- Q: How are steel coils processed for edge trimming or shearing?

- Steel coils are processed for edge trimming or shearing by first uncoiling the coil and feeding it into a machine equipped with either rotary shears or slitting knives. These tools trim or shear the edges of the coil to remove any irregularities, ensuring a precise and uniform width. The trimmed edges are then inspected for quality and smoothness before the coil is recoiled for further processing or storage.

- Q: What are the different types of steel coil slitting knives?

- There are several different types of steel coil slitting knives, including circular slitting knives, straight slitting knives, and crush-cut slitting knives. These knives are used for precision cutting and slitting of steel coils into narrower strips or sheets. Circular slitting knives feature a circular shape with sharp edges, while straight slitting knives have a straight cutting edge. Crush-cut slitting knives have a unique design that allows them to crush and cut the material simultaneously. Each type of knife is used for specific applications and offers different advantages depending on the desired outcome.

Send your message to us

Prime Hot Dipped Aluzinc Steel Sheet In Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords