PREPAINTED STEEL COIL JIS G 3312 CGCC WITH ZINC COATING 275g/m2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25.00 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PREPAINTED STEEL COIL

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

PREPAINTED STEEL COIL

Technical Standard: JIS 3312

Grade:CGCC

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package: Properly packed for ocean freight exportation in 20''container

Application:: home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

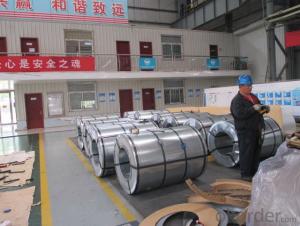

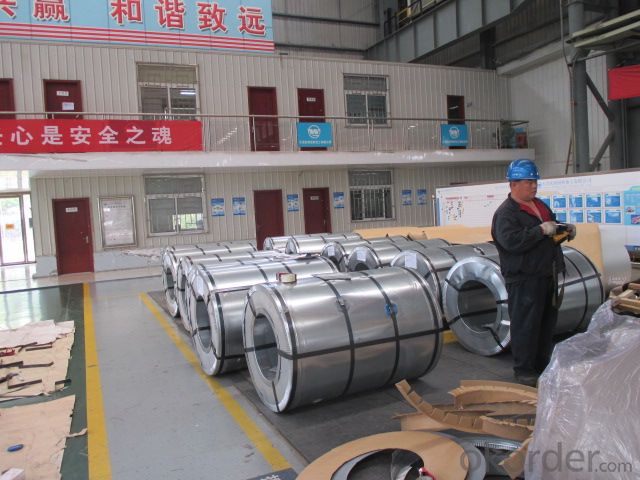

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: How are steel coils inspected for surface cleanliness?

- Steel coils are inspected for surface cleanliness through various methods such as visual inspection, magnetic particle testing, and ultrasonic testing. These techniques help identify and remove any contaminants or defects that may be present on the surface of the steel coils.

- Q: What are the main challenges in handling and processing steel coils?

- The main challenges in handling and processing steel coils include their large size and weight, the risk of damage during transportation and storage, the need for specialized equipment and facilities, ensuring proper handling to prevent injury to workers, and addressing the potential for corrosion and rust. Additionally, the variability in coil dimensions and surface conditions can pose difficulties in achieving precise and consistent processing results.

- Q: What are the different methods of levelling steel coils?

- Different methods are employed to level steel coils, depending on their specific requirements and applications. Some commonly used methods include: 1. Roller Leveling: This method utilizes a series of rollers to apply pressure on the steel coil, effectively reducing residual stresses and eliminating any waviness or curvature. It is commonly used for achieving high flatness in thinner gauge coils. 2. Stretch Leveling: In this method, the steel coil is stretched beyond its yield point to eliminate shape defects. The coil is subjected to tension in a stretcher leveler machine, which elongates the material and removes inherent stresses. It is often used for achieving greater flatness in thicker gauge coils. 3. Temper Milling: This method involves passing the steel coil through a temper mill equipped with work rolls on top and bottom. The temper mill applies tension to the coil, flattening it and improving its shape and surface quality. It is typically used for higher strength steel grades. 4. Corrective Leveling: When the steel coil exhibits significant shape defects like wavy edges or center buckles, corrective leveling is employed. This method selectively removes material from specific areas of the coil to achieve a flat and uniform surface. Laser or plasma cutting machines are often used for this process. 5. Tension Leveling: Similar to stretch leveling, tension leveling applies tension to the coil without exceeding its yield point. Bridle rolls are used to stretch the material, eliminating internal stresses and leveling the coil. It is commonly used for achieving flatness in higher strength and thinner gauge coils. These methods can be used individually or in combination, depending on the specific requirements and desired end product. Each method has its advantages and limitations, and the choice of leveling method depends on factors such as coil thickness, material properties, and desired flatness.

- Q: Im looking to learn guitar and i was wondering if steel strings are too hard to use as a beginner. I am also self teaching so any good lesson books/starting guitar recommendations are welcome !! thanks.

- Steel strings are fine for a beginner. I learned to play on Steel strings and I have always preferred them to nylon strings.

- Q: What are the environmental impacts of steel coil production?

- The environmental impacts of steel coil production include the extraction of raw materials, such as iron ore and coal, which can lead to deforestation, habitat destruction, and soil erosion. The steel manufacturing process also releases significant amounts of greenhouse gases, such as carbon dioxide, contributing to climate change. Additionally, the production of steel coils requires large amounts of water and energy, leading to water scarcity and increased carbon emissions.

- Q: What are the common surface treatments for galvanized steel coils?

- The common surface treatments for galvanized steel coils include passivation, chromate coating, and oiling. Passivation is a process where a thin layer of protective material, such as zinc phosphate or chromate, is applied onto the galvanized steel surface. This layer helps to enhance the corrosion resistance of the steel by providing a barrier against moisture and atmospheric elements. Passivation also improves the adhesion of subsequent coatings or paints that may be applied to the steel. Chromate coating, also known as chromating or chromate conversion coating, involves the application of a thin layer of chromate onto the galvanized steel surface. This coating provides an additional layer of protection against corrosion and improves the appearance of the steel. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is another common surface treatment for galvanized steel coils. This involves the application of a thin layer of oil onto the surface of the steel, which helps to prevent the formation of rust and corrosion during storage and transportation. Oiling also provides temporary protection against moisture and other environmental factors until the steel is further processed or used in its final application. These surface treatments are commonly used to enhance the performance, durability, and appearance of galvanized steel coils, ensuring that they can withstand harsh conditions and maintain their quality over time.

- Q: what do we use steel for and whyand why do we use brass for instrumentsplz help its homework and i cant find the answer anywhere : (

- Brass and steel are type of metals that mostly use for moist area and also have luxury used cause of ability of shine .Steel definitely is for anti oxide ,mostly use in area that food and liquid such as acid ,milk ,soda,water are in contact .Brass most use for electric parts and decoration for ability of conductivity and shin .

- Q: hi i was doing a little history project on guns. i was just wondering if anyone could help me find out what material was used before steel and why this material wasnt as good as steel ( its faults)thanks for your help

- The most common was bronze, which was the strongest material that could be cast, at least until the industrial revolution. Until that time, furnaces which could reach temperatures hot enough to melt steel did not exist. The only way to work with steel would have been forging, which means hammering it into shape while red-rot. Obviously, this is not a very practical method for making large thick-walled cannons (though it was done on occasion. Small arms such as pistols and muskets could be easily made of steel by hand forging.) The most practical way to make cannons was pouring molten bronze which melts at significantly lower temperature than steel. Cast iron was also used. Note that Cast Iron contains 3%-7% carbon, compared to steel which only contains between 2% to 0.2% carbon. Due to the excessive carbon content of cast iron, it's melting point is about 500 degrees lower than steel enabling it to be melted with pre-industrial furnaces. Unfortunately, cast iron is also brittle, unlike steel or bronze. This means that a defective or cracked casting could easily explode, sending iron shrapnel everywhere. (Also, maiming and killing the gun crew, an experienced gun crew was as valuable as the cannon itself!) For this reason. Cast iron cannon were usually considered a cheap, risky alternative to expensive but durable bronze.

- Q: I've played guitar for years, now I want a steel guitar. As a beginner, to learn and experiment with, which one would be better for me?

- Pedal steel is very difficult. You need to co-ordinate both hands, both feet and both knees to play it effectively. Lap steel is a lot easier. I suppose it depends how much of a challenge you want. A good lap steel guitar is usually cheaper than a good pedal steel too, so that's another consideration to take into account.

- Q: How did the growth of the steel industry influence the development of other industries?

- At least three ways: 1. Steel as a material that other industries could use to do things that couldn't be done before (for example, construction (skyscrapers, long bridges, etc.)) or could now be done at much lower cost and hence increased the size of the industry (automobiles, bearings, etc.)

Send your message to us

PREPAINTED STEEL COIL JIS G 3312 CGCC WITH ZINC COATING 275g/m2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25.00 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords