Prepainted Rolled Steel Coil For Construction roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

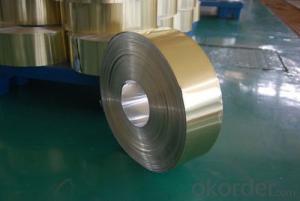

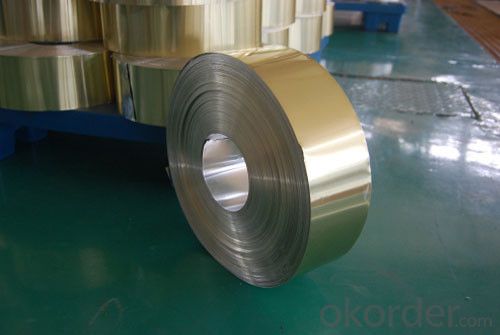

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Should I stick with the all steel kit over the acrylic tapers and steel plugs? or would the acrylic be ok? I keep hearing that steel is the best and acrylic can cause problems. I just want to do it correctly and take my time with it, no rushing.thanks

- I haven't heard anyone complain about using acrylic so I don't see why it would be a problem. Either would be fine. I prefer acrylic myself but it really doesn't matter.

- Q: What are the dimensions of steel coils used in the railway equipment industry?

- The dimensions of steel coils used in the railway equipment industry can vary depending on the specific application and requirements. However, some common dimensions for steel coils used in this industry are typically around 3 to 5 feet in width and 10 to 15 feet in length. The thickness of the steel coils can vary as well, ranging from 0.01 to 0.5 inches. It is important to note that these dimensions are not fixed and may vary based on the specific needs of the railway equipment industry, such as the type of equipment being manufactured or the specific function of the steel coils.

- Q: is a 1962 steel penny worth anything?

- Don't know that they're worth a whole lot at this time, but hold on to them. They may be at some point, and what's the loss if you keep them? May be worth something to the kids or grandkids?

- Q: My 8-year-old and 9-year-old boys have approached me with an interesting question. Does fire burn steel? One says yes, the other says no. Help me to settle yet another debate :)

- no, fire MIGHT cause steel to oxidize, depending on the alloy, but think of steel as a block of ice. Steel melts at 2800 degrees F and boils and evaporates at 5400 degrees. Some metals like magnesium can possibly catch fire but not steel

- Q: What are the different methods of storing steel coils?

- There are several methods of storing steel coils, depending on the specific requirements and constraints of the storage facility. Some of the commonly used methods include: 1. Stack storage: This method involves stacking the steel coils on top of each other in a stable manner. It is a cost-effective method, as it maximizes the use of vertical space. However, it requires careful stacking to ensure stability and prevent damage to the coils. 2. Block stacking: In this method, steel coils are arranged in blocks, with each coil placed directly on top of another. The blocks are then stacked to maximize the use of space. This method provides stability and allows for easy access to individual coils. However, it may require the use of additional equipment such as coil cradles or coil saddles to prevent damage. 3. Coil cradles: Coil cradles are specialized racks or frames that are designed to hold steel coils horizontally. They provide support and prevent the coils from rolling or shifting. This method is particularly suitable for smaller coils or when quick access to individual coils is required. 4. Coil saddles: Coil saddles are U-shaped frames that are specifically designed to hold and support steel coils vertically. They are often used in conjunction with block stacking or stack storage methods. Coil saddles provide stability and prevent the coils from rolling or collapsing. 5. Coil racks: Coil racks are steel structures that are designed to hold multiple coils in an organized manner. They may have several levels or tiers, allowing for efficient use of space. Coil racks are typically used for larger coils and can be customized to accommodate specific coil dimensions. 6. Automated storage systems: In large-scale storage facilities, automated systems such as coil cranes or coil carousels may be employed. These systems use mechanical devices to transport and store steel coils, allowing for efficient and fast retrieval when needed. They are particularly useful in high-volume operations where frequent coil handling is required. It is essential to consider factors such as coil size, weight, accessibility, and environmental conditions when determining the most suitable method of storing steel coils. Additionally, proper handling, labeling, and regular inspections are crucial to ensure the integrity and longevity of the stored coils.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using heavy-duty cranes and specialized equipment. When loading, the coils are lifted from the dockside or storage area using a crane with strong lifting capacity. They are carefully positioned onto the ship's deck, ensuring proper balance and securement to prevent any damage during transit. Unloading is done in a similar manner, with the crane carefully lifting the coils from the ship's deck and placing them onto the dock or designated storage area. Throughout the process, safety protocols are followed to ensure the smooth and efficient handling of these heavy and valuable cargo.

- Q: How are steel coils inspected for surface finish after processing?

- Steel coils are inspected for surface finish after processing through various methods such as visual inspection, surface roughness measurement, and non-destructive testing techniques like magnetic particle inspection or eddy current testing. These inspections help ensure that the steel coils meet the required surface finish standards and are free from any defects or imperfections.

- Q: Hey do you know what is Steel Arch Building and how it looks like exactly??

- Steel okorder /

- Q: How are steel coils used in the production of industrial shelving?

- Steel coils are used in the production of industrial shelving as they are typically cut and shaped into various components, such as uprights, beams, and braces, which are then assembled to create sturdy and durable shelving units. The coils provide the necessary strength and stability required to support heavy loads and withstand the demands of an industrial environment.

- Q: How are steel coils used in the production of agricultural machinery?

- Steel coils are used in the production of agricultural machinery as a primary material for various components and structures such as frames, chassis, and panels. The coils are typically cut, shaped, and welded to create the desired parts, ensuring strength, durability, and reliability in the machinery.

Send your message to us

Prepainted Rolled Steel Coil For Construction roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords