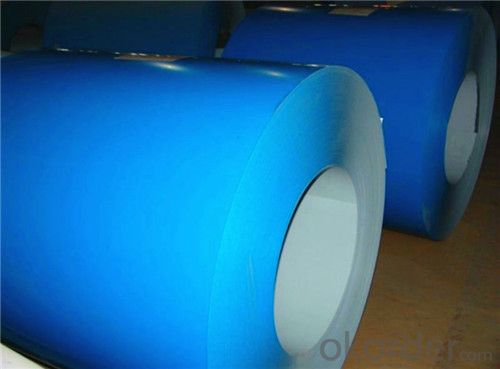

Prepainted Rolled steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the factors affecting the strength of steel coils?

- The strength of steel coils can be influenced by several factors. These include the grade of steel used, the manufacturing process employed, the thickness and width of the coils, the quality of their surface, how they are stored and handled, and the environmental conditions they are exposed to. When choosing and using steel coils, it is crucial to take these factors into account to ensure that they meet the necessary strength requirements for their intended use.

- Q: What are the different types of steel coil coatings for corrosion resistance?

- There are several different types of steel coil coatings that are specifically designed to provide corrosion resistance. These coatings can be categorized into two main types: organic coatings and metallic coatings. 1. Organic Coatings: - Polyester: Polyester coatings are commonly used for steel coil applications due to their excellent corrosion resistance and durability. They offer good weatherability and resistance to chemicals, making them suitable for outdoor applications. - Polyvinylidene Fluoride (PVDF): PVDF coatings are highly resistant to UV radiation, weathering, and chemicals. They provide exceptional durability and are often used in demanding environments such as coastal areas or industrial settings. - Polyurethane: Polyurethane coatings offer excellent abrasion resistance and provide a high level of corrosion protection. They are commonly used in applications where there is a higher risk of mechanical damage or exposure to harsh conditions. - Epoxy: Epoxy coatings provide excellent adhesion and chemical resistance. They are often used in industrial applications where resistance to chemicals, solvents, and oils is required. 2. Metallic Coatings: - Galvanized Coatings: Galvanized coatings involve applying a layer of zinc to the steel surface through a hot-dip or electroplating process. This creates a barrier between the steel and the surrounding environment, providing effective corrosion protection. Galvanized coatings are widely used in various industries due to their cost-effectiveness and good durability. - Galvannealed Coatings: Galvannealed coatings are similar to galvanized coatings but undergo an additional heat treatment process. This results in a coating with increased hardness and improved paint adhesion, making it suitable for applications that require additional surface protection or paintability. It is important to consider the specific requirements of the application and the level of corrosion resistance needed when selecting the appropriate steel coil coating. Consulting with coating manufacturers or industry experts can help determine the most suitable coating for a particular application.

- Q: How are steel coils uncoiled?

- Steel coils are typically uncoiled using a mechanical device called a decoiler. The decoiler feeds the steel coil through a set of rollers, which gradually unwinds and straightens the coil, allowing it to be used for various applications.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- of course you couldn't find it, the weigh depends on the size of the piece. What you are looking for, I think, is density. Below are a few tables, there are lots more. .

- Q: How are steel coils inspected for yield strength using tensile testing?

- Steel coils are inspected for yield strength using tensile testing by taking a sample from the coil and subjecting it to a controlled force until it reaches its yield point. The force required to cause permanent deformation in the sample is measured, and this value represents the yield strength of the steel coil.

- Q: What are the different methods of leveling steel coils?

- There are several methods of leveling steel coils, including roller leveling, stretcher leveling, and tension leveling. Roller leveling uses a series of rollers to gradually bend the steel to achieve a flat surface. Stretcher leveling involves stretching the steel through hydraulic or mechanical means to remove any residual stresses and straighten it. Tension leveling applies tension to the steel coil while passing it through a series of rollers, effectively elongating the material to remove any waviness or curvature.

- Q: Hi there! I just purchased two cookie sheets labeled as non-stick 100% carbon steel. I've never heard of carbon steel before, and I'm trying to be careful about not using certain products that are harmful to health such as aluminum and Teflon. Is this a safe metal choice for baking?

- This Site Might Help You. RE: Is 100% carbon steel baking sheet safe? Hi there! I just purchased two cookie sheets labeled as non-stick 100% carbon steel. I've never heard of carbon steel before, and I'm trying to be careful about not using certain products that are harmful to health such as aluminum and Teflon. Is this a safe metal choice for...

- Q: Steel resist tension. Then why we provide steel in compression zone ?

- There are several reasons to add compression steel. Keep in mind, supported steel (meaning it can't buckle) resists compression as well. Compression steel helps reduce long term deflections. Concrete creeps under sustained loads. Steel lessens the compression, meaning less sustained compressive stress to cause creep deflection. It makes members more ductile. Since the steel takes some of the compressive stress, the compression block depth is reduced, increasing the strain in the tension steel at failure, resulting in more ductile behavior (the moment at first yield remains largely the same with compression steel added, but the increase in capacity after yield is significant). Compression steel insures that the tension steel yields before the concrete crushes, meaning it helps change the failure mode to tension controlled. It makes beams easier to construct. With bars in the top and bottom, you have longitudinal reinforcement in all 4 corners of the shear stirrups to keep them in place when pouring the concrete. Also, for continuous members, its often easier to run your negative moment steel the full length of the beam rather than trying to cut it off in the positive moment regions. Serviceability concerns. You're going to end up putting steel in that region anyway to for temperature and shrinkage.

- Q: What is the difference between a steel strip and a coil? The steel strip is flat steel, and the steel coil is made of steel. Is that correct?

- A steel strip is a steel strip of relative range, and can be called a steel strip when the width is less than 1000.

- Q: What are the safety regulations for steel coil production facilities?

- Safety regulations for steel coil production facilities vary depending on the specific country or region, but there are some common safety measures that are typically implemented in these facilities. One key safety regulation is the proper training and education of employees. All workers in steel coil production facilities should be trained on the potential hazards they may encounter, as well as the proper safety procedures to follow. This includes training on handling heavy machinery, operating cranes or forklifts, and understanding the risks associated with working in a high-temperature environment. Another important safety regulation is the maintenance and inspection of equipment. Regular inspections of machinery and equipment should be conducted to ensure they are in proper working condition and do not pose any safety risks. Furthermore, maintenance procedures should be implemented to address any issues or malfunctions promptly. Fire safety is also a crucial aspect of safety regulations in steel coil production facilities. Fire prevention measures such as the installation of fire alarms, sprinkler systems, and fire extinguishers should be in place. Regular fire drills should also be conducted to ensure that all employees are aware of the evacuation procedures and can respond quickly and effectively in case of a fire emergency. Personal protective equipment (PPE) is another vital safety requirement in steel coil production facilities. Employees should be provided with appropriate PPE such as safety glasses, helmets, gloves, and steel-toed boots to protect them from potential hazards such as falling objects, sharp edges, and high temperatures. Additionally, safety regulations often require the implementation of safety barriers and guards around machinery and equipment to prevent accidents and injuries. This includes safety gates, railings, and protective covers to restrict access to hazardous areas and prevent unauthorized entry. Regular safety audits and inspections should be conducted by relevant authorities or safety professionals to ensure compliance with safety regulations. Companies should also encourage a culture of safety by promoting open communication about safety concerns, providing safety training and refresher courses, and rewarding employees for their adherence to safety protocols. It is important to note that safety regulations may vary from one jurisdiction to another, and it is always advisable to consult the specific regulations applicable in the country or region where the steel coil production facility is located.

Send your message to us

Prepainted Rolled steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords