Prepainted Rolled Steel Coil For Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

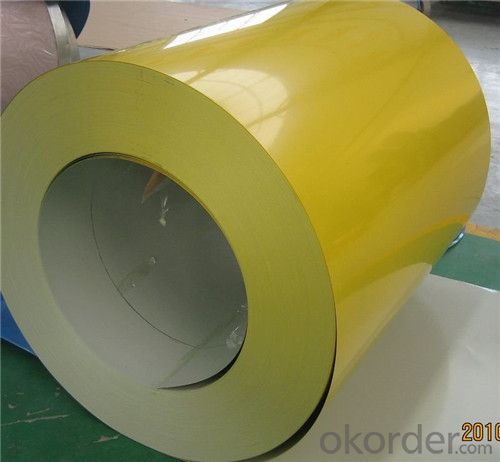

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- i have steel and i like the way it sounds but i like nylon better

- Q: where can i find information online about steel residential homes that use solar energy?

- Steel okorder

- Q: What are the challenges in coil recoiling?

- Coil recoiling, which is also known as coil winding, brings about a range of challenges that depend on the specific application and requirements. Some of the common hurdles encountered in coil recoiling are as follows: 1. Precision and accuracy: Achieving precise and accurate winding is vital for optimal coil performance. It is crucial to maintain consistent tension throughout the winding process, ensure proper alignment, and control the speed in order to prevent variations in the electrical properties of the coil. 2. Wire management: Managing the wire during the recoiling process can be difficult. The wire may be fragile, prone to tangling, or have specific handling requirements, such as being sensitive to magnetic or thermal influences. Employing proper wire management techniques, such as tension control, wire guide systems, and spooling mechanisms, is necessary to prevent wire damage and ensure uniform winding. 3. Space limitations: In many cases, coils need to fit within specific space constraints. Designing and winding coils to fit compact spaces can be challenging, particularly when considering the required number of turns, wire size, insulation, and any additional components or structures that may need to be incorporated. 4. Material selection: The selection of the appropriate wire and insulation material is crucial for optimal coil performance and durability. Factors such as electrical conductivity, thermal properties, mechanical strength, and chemical resistance must be taken into account to ensure that the coil can withstand the operating conditions and environmental factors it will encounter. 5. Heat dissipation: Coils often generate heat during operation, especially in high-power applications. Efficient heat dissipation is crucial to prevent overheating and ensure the longevity of the coil. Techniques such as designing the coil with proper ventilation, utilizing cooling mechanisms, or incorporating heat sinks are employed to address this challenge. 6. Quality control: Ensuring consistent quality in coil recoiling can be challenging due to factors such as variations in wire properties, operator skill, equipment calibration, and environmental conditions. Robust quality control measures, such as conducting regular inspections, performing electrical tests, and monitoring process parameters, need to be implemented to maintain consistent coil performance. In summary, coil recoiling demands meticulous attention, precision, and adherence to specific requirements in order to overcome the challenges and produce high-quality coils that meet the desired performance criteria.

- Q: I am working on a hydrogen generator, but the stainless steel I am using corrodes and turns the water brown. Can anyone tell me if there is stainless steel that does not corrode, and if so, what is it called and where can I get some.Thank you.

- Look okorder /

- Q: What are the factors that affect the price of steel coils?

- There are several factors that can affect the price of steel coils. These include the cost of raw materials, such as iron ore and coal, which are used in the production of steel. Fluctuations in these commodity prices can have a direct impact on the price of steel coils. Other factors include supply and demand dynamics, changes in production capacity, transportation costs, and global economic conditions. Additionally, factors like trade policies, tariffs, and currency exchange rates can also influence the price of steel coils.

- Q: What are the different types of steel coil storage locations?

- There are various types of steel coil storage locations, including open yards, covered warehouses, coil racks, and specialized coil storage systems.

- Q: What are the different methods of levelling steel coils?

- There are several methods of leveling steel coils, including roller leveling, stretcher leveling, and temper leveling.

- Q: like, what can steel make?

- buildings bridges automobiles elevators railroads and railroad equipment appliances and many many more. Steel is used almost everywhere. reference: Iron and steel are used widely in the construction of roads, railways, infrastructure, and buildings. Most large modern structures, such as stadiums and skyscrapers, bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure will employ steel for reinforcing. In addition to widespread use in major appliances and cars (Despite growth in usage of aluminium, it is still the main material for car bodies.), steel is used in a variety of other construction-related applications, such as bolts, nails, and screws.[66] Other common applications include shipbuilding, pipeline transport, mining, offshore construction, pipeline transport, aerospace, white goods (e.g. washing machines), heavy equipment (e.g. bulldozers), office furniture, steel wool, tools, and armour in the form of personal vests or vehicle armour (better known as rolled homogeneous armour in this role). .

- Q: How do steel coil manufacturers handle international shipping requirements?

- Steel coil manufacturers ensure that their products meet transportation standards and regulations for international shipping. This involves following specific packaging requirements, using appropriate containers, and securing the coils to prevent damage during transit. In order to meet international shipping requirements, manufacturers must also comply with customs regulations and documentation. They need to prepare accurate and complete paperwork, such as commercial invoices, packing lists, and bills of lading, to ensure smooth customs clearance procedures. Furthermore, steel coil manufacturers often collaborate with freight forwarders or shipping agents who specialize in international logistics. These professionals have extensive knowledge of shipping regulations, routes, and carriers, and can assist with arranging transportation, negotiating freight rates, and handling necessary paperwork. Manufacturers may also choose to use intermodal transportation, which involves utilizing multiple modes of transportation like trucks, trains, and ships. This allows for more efficient and cost-effective shipping, especially for long-distance or international shipments. Additionally, steel coil manufacturers may consider obtaining insurance coverage to protect their products during transit. Insurance provides financial compensation in case of any damage, loss, or delays during the shipping process. Overall, steel coil manufacturers handle international shipping requirements through careful planning, adherence to regulations, collaboration with logistics experts, and consideration of various transportation options. This ensures that their products reach international destinations safely, on time, and in compliance with all relevant regulations.

- Q: What are the environmental and social impacts of mining, processing and using steel?

- It contains less than 0.25 % carbon. These steels are hot worked and produced for beam and structural application. Low carbon steels are not hardened appreciably by hardening process of heat treatment. A decrease in carbon content improves ductility mild steels are used for wires, rods, thin sheets, solid drawn tube, boiler plates, steel joints, channels and angles, structural sections, drop forgings. they are further classifies into dead mild, and mild steel dead mild steel It contains 0.05% to 0.15% carbon. It is used for making steel wires, sheets, rivets, screws, pipe, nail and chain. It has a tensile strength of 390 N/mm2 and a hardness of about 115 BHN. there are many company which produce their products from this raw material like tube, pipe, S31803 Duplex tube fitting, pipe fitting etc

Send your message to us

Prepainted Rolled Steel Coil For Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords