Prepainted rolled Steel Coil For Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

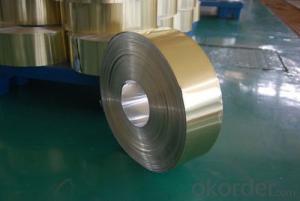

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I am buying my boyfriend a steel guitar for our one year anniversary and I was curious what brand or company I should look into. I want something high quality yet traditional. Money is not really an issue but I don't exactly want to spend an arm and a leg either.Thank you in advance!

- Pedal steel or lap steel? Or do you perhaps mean a steel-STRING guitar, or a steel-bodied resonator guitar? Might help weed out irrelevant replies if you were to clarify.

- Q: Why can hot rolled coils be placed outside?

- Because hot-rolled steel coils are generally used as raw material for semi-finished products, they have to be further used for pickling and cold rolling to make more use. The rust and dust can be removed after pickling

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry.

- Q: How are steel coils used in the production of railway tracks?

- Railway tracks rely heavily on steel coils, which are indispensable in their production. These coils, typically made from top-notch steel, are utilized to create the rails that constitute the bedrock of the tracks. The process commences with the unwinding of the steel coils, which are then fed into a sequence of machines that mold and fashion them into the desired rail profile. Initially, the steel coils are passed through a rolling mill, where they undergo gradual flattening and shaping, thereby transforming into elongated steel strips. This technique, known as hot rolling, involves heating the steel to high temperatures to enhance its pliability. The rolling mill exerts substantial pressure on the steel, progressively molding it into the desired rail shape. Once the steel coils have been rolled into the requisite form, they are subsequently severed into individual rail lengths. The length of these rails may vary depending on the specifications of the railway track being produced. The rail lengths then undergo further processing to eliminate any flaws and straighten them out. Following this initial shaping and processing, the rails undergo a series of supplementary treatments. These treatments may entail heat treatment to bolster their strength and durability, as well as various surface treatments to prevent corrosion and wear. Once the rails have undergone all the necessary treatments, they are ready for installation on the railway track. They are laid out meticulously in a predetermined pattern, with each rail securely fastened to the sleepers or ties. The continuous length of steel provided by the coils ensures a seamless and uniform track, enabling trains to travel smoothly and safely. In conclusion, steel coils are crucial components in the production of railway tracks. They are utilized to manufacture the rails that serve as the foundation of the tracks, guaranteeing durability, strength, and a smooth surface for trains to traverse. The use of high-quality steel coils in this process is essential to ensure the safety and efficiency of railway transportation.

- Q: What are the dimensions of steel coils used in the household appliance industry?

- The dimensions of steel coils used in the household appliance industry can vary depending on the specific application and manufacturer. However, common dimensions for steel coils in this industry range from 0.20mm to 3.0mm in thickness and 600mm to 1500mm in width.

- Q: How are steel coils used in the production of containers?

- Steel coils are used in the production of containers as they are the primary material for manufacturing container bodies. These coils are shaped and welded into the desired container shape, providing strength and durability to the final product.

- Q: How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed and shaped into the desired size and shape. The coils are first uncoiled and straightened, then cut into shorter lengths. These shorter lengths are then bent and twisted to create the necessary patterns and shapes, which provide enhanced strength and durability to the reinforcement bars.

- Q: case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

- Q: I personally don't believe the story of 8 guys who flew small planes can navigate passenger jets into buildings hundreds of miles away with that precision. It just doesn't make sense.I am wondering what the story surrounding the molten steel was, how could molten steel have been produced when fuel from the planes wasn't hot enough (it melts at 2850 degrees)?

- that's just it: there wasn't very much molten steel for the very reason you point out. Jet fuel burns at 800° to 1500°F. This is not hot enough to melt structural steel. However, engineers say that for the World Trade Center towers to collapse, their steel frames didn't need to melt, they just had to lose some of their structural strength. Steel will lose about half its strength at 1,200 degrees F. The steel will also become distorted when heat is not a uniform temperature. after the collapse, a LOT of folks took a look at the remains. the result was the conclusion that the fire caused the central core of the building to weaken. When the floors collapsed one on top of the other, the weight was too much for the weaked core to bear, causing the result we are all familiar with. hope this helps

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- If it does not could desire to hold an part o.k. then 440 stainless could be your appropriate guess. I want severe carbon steel. yet they require alot of cleansing and oiling or they're going to rust.

Send your message to us

Prepainted rolled Steel Coil For Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords