prepainted Rolled Steel Coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

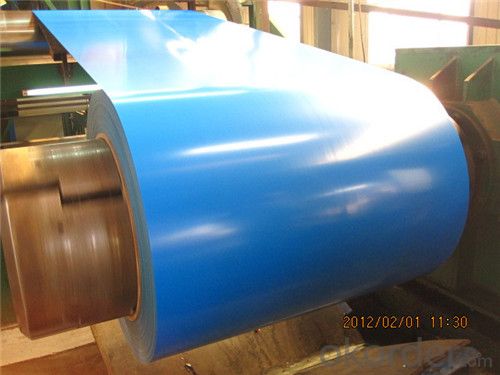

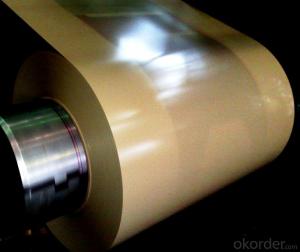

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the production of agricultural systems?

- Steel coils are used in the production of agricultural systems as they are often shaped into various components like frames, supports, and structures. These components provide strength, durability, and stability to agricultural equipment such as tractors, harvesters, and irrigation systems, ensuring their long-term functionality and reliability in demanding farming environments.

- Q: How are steel coils used in various industries?

- Steel coils are used in various industries for a wide range of applications. In the automotive industry, they are used to manufacture car bodies, chassis, and parts. In construction, steel coils are used in the production of beams, columns, and roofing materials. They are also utilized in the manufacturing of appliances, electrical equipment, and machinery. Additionally, steel coils are essential in the production of pipes, tubes, and other structural components. Overall, steel coils play a crucial role in providing strength, durability, and versatility to multiple industries.

- Q: Is steel harder than iron or is iron harder than steel?Please explain... and help!Thanks

- steel is harder than iron Iron is a chemical element. It is a strong, hard, heavy gray metal. It is found in meteorites. Iron is also found combined in many mineral compounds in the earth's crust. Iron rusts easily and can be magnetized and is strongly attracted to magnets. It is used to make many things such as gates and railings. Iron is also used to make steel, an even harder and tougher metal compound. Steel is formed by treating molten (melted) iron with intense heat and mixing it (alloying) with carbon. Steel is used to make machines, cars, tools, knives, and many other things.

- Q: I just bought some cheap earrings from this beauty supply store but they said surgical steel So will they prevent my ears from bleeding / infection ?

- Surgical steel is a grade of steel often used in medical appliances like tweezers, forceps, etc. It's generally non-reactive and considered very safe. It doesn't contain any special properties against infection--you still have to observe basic hygiene and clean your piercings properly--but most people can wear surgical steel earrings without a problem. However, if you have a contact allergy to base metals like nickel, surgical steel may cause redness or irritation because of the metals used in it. If cheap rings or necklaces make your skin break out in a rash you should NOT wear surgical steel.

- Q: What are the different types of steel surface finishes for coils?

- There are several types of steel surface finishes for coils, including mill finish, galvanized finish, coated finish, and polished finish. Mill finish refers to the natural, untreated surface of the steel, which may have slight imperfections. Galvanized finish involves coating the steel with a layer of zinc to enhance corrosion resistance. Coated finishes can include various types of coatings such as paint, epoxy, or polymer to provide protection and aesthetic appeal. Lastly, a polished finish involves buffing or grinding the steel surface to create a smooth, reflective appearance.

- Q: How are steel coils different from steel sheets?

- Steel coils and steel sheets are both made from the same material, steel, but they differ in terms of shape and size. Steel coils are long, continuous rolls of steel that are typically wound up into a coil shape. They are generally used for industrial purposes and can be processed further to create various products like pipes, tubes, or automotive parts. On the other hand, steel sheets are flat pieces of steel that are available in various thicknesses. They are commonly used in construction, manufacturing, and fabrication processes where a flat surface is required, such as roofing, cladding, or panels.

- Q: What are the dimensions of steel coils used in the structural component industry?

- The dimensions of steel coils used in the structural component industry can vary depending on the specific application and requirements. However, common dimensions for steel coils in this industry typically range from 0.5 to 3.0 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coils can vary but is often around 2000 to 2500 meters.

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: How are steel coils inspected for surface cleanliness using cleanliness tests?

- Steel coils are inspected for surface cleanliness using cleanliness tests to ensure that they meet the required quality standards. These tests involve various methods to assess the presence of contaminants, such as dirt, oil, grease, rust, or scale, on the surface of the steel coils. One commonly used cleanliness test is the visual inspection, where trained inspectors visually examine the surface of the coils for any visible contaminants. They look for any signs of staining, discoloration, or foreign substances that may affect the quality of the steel. Another cleanliness test is the wipe test, where a clean cloth or wipe is used to wipe the surface of the steel coil. This cloth is then analyzed for the presence of contaminants using techniques like gravimetric analysis or solvent extraction. The amount of contaminants collected on the cloth can be measured, providing an indication of the cleanliness of the steel surface. Surface roughness tests are also performed to assess cleanliness. A roughness gauge is used to measure the roughness of the steel surface, which can indirectly indicate the presence of contaminants. If the surface roughness measurements are higher than the specified limits, it suggests the presence of contaminants affecting the cleanliness of the steel. In addition to these tests, cleanliness tests may also involve techniques like wetting tension measurement, water break test, or contact angle measurements. These tests evaluate the surface energy and wetting properties of the steel, which can be affected by the presence of contaminants. By conducting cleanliness tests, steel coils can be thoroughly inspected for surface cleanliness. These tests help in identifying any potential contaminants that may compromise the quality and performance of the steel. By ensuring the surface cleanliness of steel coils, manufacturers can provide high-quality products that meet the stringent requirements of various industries.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

Send your message to us

prepainted Rolled Steel Coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords