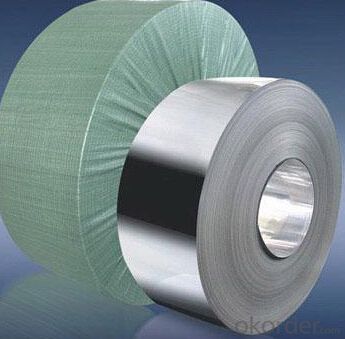

Prepainted Hot Dipped Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description.

Export Markets:Global

Additional Info.

Packing:Seaworthy

Origin:China

HS Code:72104900

Production Capacity:10000tons Per Month

Product Description

We are specialized in types of hot dipped galvanized, galvalume, prepainted steel products, corrugated steel sheet, etc.

Poduce Name: Prepainted Hot Dipped Steel Coil

Standard: JIS G3302, JIS G3312, ASTM A653M/A924M 1998

Grade: Q195 - Q235 and 08AL, SPCC, SPCD, SPCE, 08.10.15, SGCC (DX51D+Z) SGCD(DX52D+Z) etc.

Surface treatment: Chromated, unoiled/oiled, bright finished, spangle, fingerprint resistance.

Surface protection: PE, PVDF, SMP, HDP, etc.

Thickness: 0.20mm-2.0mm

Width: 1000mm, 1200mm, 1250mm, 1500mm, or according to your request.

Zinc coating: 80g-275GSM

Coil weight: 3-27 tons

Paint: Polyester silicon modified polyester, PVC sol, polyvinylidene chloride

Colour: RAL, or other series.

Application:

Architectural applications: Outdoor construction: Roof, the roof structure, balcony panels, water downpipe, window frames, gates, garage doors, roller shutter doors, kiosks, shutters, guard room, shower enclosure, refrigerated trucks and so on.

Indoor applications: Door, partitions, door frames, housing, light steel structure, sliding doors, screens, ceilings, bathroom interior, the elevator built, the elevator vestibule and so on.

Electrical Appliances: Refrigerators, frozen food display cabinets, washing machines, electric ovens, vending machines, air conditioners, copiers, switchgear, instrument cabinets, electric fans, vacuum cleaners and so on.

Transport: Car ceiling, backplane, hoardings, interior trim panels, car shell, trunk panels, car dashboard, console shell, tram, train ceiling, partitions, wall, door, ships separated Swatchesdoors, furniture board, flooring, container, etc.

Sheet metal processing and furniture applications: Ventilation and heating stoves, water heaters, shell, counters, shelves, signs, wardrobe, desk, bedside cabinets, chairs, lockers, file cabinets, bookshelves.

Exact Rate As Per Your Request.

| Color coated similar grades comparison table | |||||

| JISG 3312-1994 | |||||

| Q/BQB 440-2003 | |||||

| TDC51D(TSt01,TSt02,TSt03) | CGCC | ||||

| TDC52D | CGCD1 | ||||

| TDC53D | - | ||||

| TS280GD(TStE28) | CGC400 | ||||

| TS350GD(TStE34) | CGC440 | ||||

| TS550GD | CGC570 | ||||

| TSECC ,TBLCE | - | ||||

| TSECD ,TBLDE | - | ||||

| TSECE ,TBUSDE | - | ||||

| Q/BQB 445-2004 | AS 2728-1997a(AS 1397-2001) | JISG 3322-1998 | |||

| TDC51D+AZ | (G2+AZ) | CGLCC | |||

| TDC52D+AZ | (G3+AZ) | CGLCD | |||

| TS250GD+AZ | (G250+AZ) | - | |||

| TS300GS+AZ | (G300+AZ) | - | |||

| TS350GD+AZ | (G350+AZ) | CGLC490 | |||

| TS550GD+AZ | (G550+AZ) | CGLC570 | |||

| The coating surface structure classification | |||||

| classification | item | code | |||

| application | Building Exterior | JW | |||

| Building inside | JN | ||||

| Steel window | GC | ||||

| Household electrical appliances | JD | ||||

| funiture | JJ | ||||

| others | QT | ||||

| Coated surface state | Coating plate | TC | |||

| Embossing plate | YA | ||||

| Printing plate | YI | ||||

| Paint types | polyester | PE | |||

| Silicone modified polyester | SMP | ||||

| Poly vinylidene fluoride | PVDF | ||||

| Substrate types | Galvanized sheet | DX | |||

| Hot galvanized plate | Finishing zinc flower | ||||

| Spangle | |||||

| Coating structure | Upper surface | First coating | |||

| two coating | First coating | ||||

| two coating | two coating | ||||

| Supplier standards and grades | |||||

| The Grades and use of color coated sheet | Grades, standards and types of substrate | ||||

| Grades | applications | Grades | standards | type | |

| TDC51D | General use | DC51D+Z | Q/BQB 420 | Hot galvanized plate | |

| TDC52D | Stamping | DC52D+Z | |||

| TDC53D | deep Stamping | DC53D+Z | |||

| TS280GD | Structure | S280GD+Z | |||

| TS350GD | Structure | S350GD+Z | |||

| TS550GD | Structure | S550GD+Z | |||

| TSECC | General use | SECC | Q/BQB 430 | Galvanized sheet | |

| TSECD | Stamping | SECD | |||

| TSECE | deep Stamping | SECE | |||

| TBLCE | General use | BLCE+Z | |||

| TBLDE | Stamping | BLDE+Z | |||

| TBUSDE | deep Stamping | BUSDE+Z | |||

| TDC51D+AZ | Cold forming | DC51D+AZ | Q/BQB 425 | Hot dip aluminized zinc plate | |

| TDC52D+AZ | Cold forming | DC52D+AZ | |||

| TS250GD+AZ | Structure | S250GD+AZ | |||

| TS300GD+AZ | Structure | S300GD+AZ | |||

| TS350GD+AZ | Structure | S350GD+AZ | |||

| TS550GD+AZ | Structure | S550GD+AZ | |||

| Available specification range | |||||

| Item | Nominal Size | ||||

| Nominal thickness | 0.22-1.30 | ||||

| Nominal width | 700-1250 | ||||

| nominal length of steel plate | 1000-4000 | ||||

- Q: What are the different methods of transporting steel coils?

- There are several methods of transporting steel coils, including using flatbed trucks, railcars, and ocean vessels. Flatbed trucks are commonly used for short distances and local deliveries, while railcars are utilized for longer distances and intermodal transportation. For international shipments, steel coils are typically transported on ocean vessels, either in containers or as breakbulk cargo. The choice of method depends on factors such as distance, destination, and cost-effectiveness.

- Q: How do you calculate the weight of a steel coil?

- To calculate the weight of a steel coil, you need to know the dimensions of the coil, specifically its length, width, and thickness. Then, you can use the density of steel (usually around 7850 kg/m³) and the formula: weight = length x width x thickness x density.

- Q: What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel products across various sectors such as construction, automotive, and infrastructure is contributing to the growth of the industry. Steel coils are widely used in these sectors for manufacturing various products such as automobiles, buildings, bridges, and pipelines. Secondly, rapid industrialization and urbanization in emerging economies are fueling the growth of the steel coil industry. Countries like China, India, and Brazil are witnessing significant infrastructure development and construction activities, which require a large amount of steel coils for various applications. Additionally, technological advancements in the manufacturing process and the use of advanced steel alloys are driving the growth of the industry. These advancements have led to the production of high-quality steel coils that offer better strength, durability, and corrosion resistance. Moreover, the growing focus on sustainable and eco-friendly practices is also driving the growth of the steel coil industry. Steel is a highly recyclable material, and the increasing awareness about the environmental benefits of using steel is boosting its demand. Furthermore, favorable government policies and initiatives to promote domestic steel production and reduce imports are also contributing to the growth of the industry. Governments are implementing measures such as import tariffs and subsidies to support local steel manufacturers, which is driving the demand for steel coils. In conclusion, the factors driving the growth of the steel coil industry include increasing demand from various sectors, rapid industrialization, technological advancements, environmental awareness, and supportive government policies.

- Q: What are the different types of steel coil packaging materials for export?

- There are several different types of steel coil packaging materials that are commonly used for export: 1. Steel Strapping: This is one of the most common and widely used materials for packaging steel coils. Steel strapping is strong and durable, providing excellent protection during transportation. It is available in different widths and thicknesses to accommodate different coil sizes. 2. Stretch Film: Stretch film is a flexible and elastic material that is often used to wrap steel coils. It provides a tight and secure packaging, preventing the coils from shifting or falling during transit. Stretch film is also lightweight, which helps to reduce shipping costs. 3. Corrugated Cardboard: Corrugated cardboard is often used as an outer packaging material for steel coils. It provides additional protection against external impacts and acts as a cushioning material. Corrugated cardboard is available in various strengths and sizes to suit different coil dimensions. 4. Wooden Crates: Wooden crates are a popular choice for packing larger steel coils. They provide a sturdy and robust packaging solution, offering excellent protection against impacts, moisture, and other environmental factors. Wooden crates can be customized to fit specific coil sizes and are often used for heavy-duty or long-distance shipments. 5. Plastic Strapping: Plastic strapping is an alternative to steel strapping, especially for lighter coils. It is lightweight, easy to handle, and resistant to rust and corrosion. Plastic strapping is available in different colors, allowing for easy identification and sorting. 6. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging materials are used to protect steel coils from corrosion during export. These materials release a vapor that forms a protective layer on the surface of the coils, preventing rust and corrosion even in high humidity or harsh environments. It is important to consider the size, weight, and specific requirements of the steel coils when choosing the appropriate packaging material for export. Additionally, compliance with international shipping regulations and standards should be ensured to guarantee a safe and efficient transportation process.

- Q: How are steel coils used in the manufacturing of transmission systems?

- Steel coils are used in the manufacturing of transmission systems as they are shaped and formed into various components such as gears, shafts, and bearings. These components provide strength, durability, and precision to the transmission system, ensuring smooth power transfer and efficient operation of vehicles and machinery.

- Q: Alright, First off i have an old plywood military box with galvanised steel corners, hinges etc (any part that must be strong) and its rusting! Some of the pieces have discoloration (like an oil stain on them) and other parts are full of this metallic dust. 1) Should i remove this box from my room?2) Is there any way or should i remove the powder on the part?3) Does this pose a serious health hazard?4) What are the oil stains?

- Dear HC, You have a great military box and a cool conversation piece. Take a vacuum and clean the dust. Take some 0000 steel wool and use on the steel parts. This will take some elbow grease! If this doesn't work try some 320 grit sand paper. lightly sand the wood and brush polyurethane on everything . The box doesn't pose any health problems. Also you might find that the box will bring a pretty good price if you decide to sell. Good luck. Sniper

- Q: What are the common coil widths and thickness combinations available for steel coils?

- The common coil widths and thickness combinations available for steel coils vary depending on the specific requirements and industry standards. However, there are some standard sizes that are commonly available in the market. For coil widths, the most common standard sizes range from 600mm to 2000mm. These widths are widely used in various industries such as automotive, construction, and manufacturing. However, custom widths are also available to meet specific project needs. As for the thickness combinations, steel coils are typically available in a range of thicknesses. The most common thicknesses for steel coils are between 0.4mm and 3mm. However, thicker or thinner options are available depending on the specific application. It is important to note that these standard sizes and thickness combinations may vary based on the specific steel grade, manufacturing process, and the supplier's capabilities. It is always recommended to discuss the required specifications with the supplier or manufacturer to ensure the availability of the desired coil widths and thickness combinations.

- Q: How can steel coils be recycled?

- Steel coils can be recycled by first removing any contaminants or coatings from the surface. The coils are then shredded into smaller pieces and melted in a furnace. The molten steel is then formed into new coils or other steel products.

- Q: What are the common coil diameters available for steel coils?

- The common coil diameters available for steel coils vary depending on the specific industry and application. However, some of the most common coil diameters for steel coils typically range from 24 inches to 72 inches. These diameters are often used in various sectors such as automotive, construction, and manufacturing. It is important to note that the specific coil diameter required may differ based on factors such as the size and weight of the material being coiled, the equipment being used to handle the coils, and the specific requirements of the end-use application.

- Q: When maintaining a japanese knife: Is a honing steel still necessary if I have a fine 3000/8000 grit whetstone?which do you prefer?

- A steel is to clean off an edge and remove any bends on the bevel, it is not directly for sharpening as it removes no material from the knife (or should not). A whetstone, however fine, does remove material. A steel to maintain an edge, a stone to restore an edge. They are different items for different purposes.

Send your message to us

Prepainted Hot Dipped Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords