Prepainted Galvanized Steel Sheet in Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Defination of Prepainted Galvanized Steel Coil

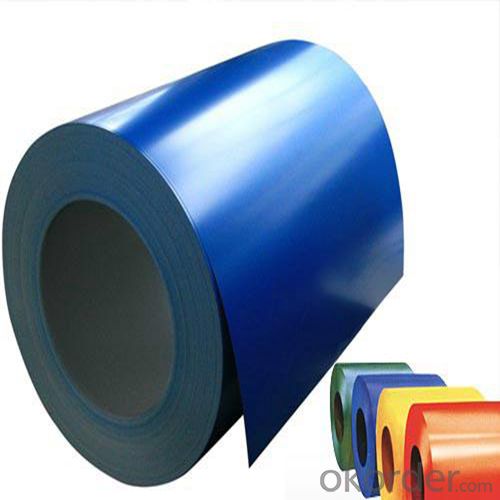

Pre-painted coils are produced by coating a layer of paint on the surface of cold rolled, galvanized or galvalumed coils. Aesthetic appeal and durability are the key festures of color coated steel coil. A wide selection of colors is available to the customer and paints designed to meet specific end use could be specified.

2. Applications of Prepainted Galvanized Steel Coil

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

3. Specifications of Prepainted Galvanized SteelCoil

Standard: ASTM;ASTM;JIS;GB

Grade: SGCC;(DX51D)

Thickness: 0.12-1.2mm

Width: 750-1250mm

Length: Coil or customer's requirements

Zinc Coating: 60-140g/m2

Painting : Top side from 15-25um; Bottom side from 5-10 um

Color : RAL numbers or customers' sample color

Application: building trade, electric apparatus, furniture and transport service

Production arts and crafts : Double coated double drying

Coil ID: 508mm

Coil Weight: 3-6 Ton

Type :coil

Packaging Detail: Fully seaworthy export packing with paper tube or as per customer's requirements

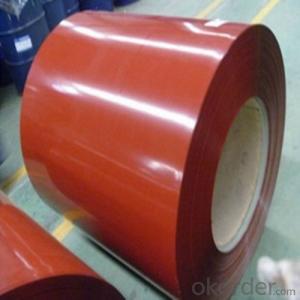

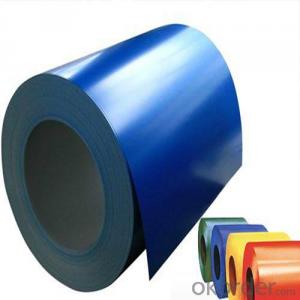

4. Prepainted Galvanized Steel Coil Images

5. Advantages of Our Prepainted Galvanized SteelCoil

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

6. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils uncoiled?

- Steel coils are typically uncoiled using a machine called a decoiler or uncoiler, which gradually unwinds the coil by feeding it through a set of rollers. The rollers apply tension to the coil, allowing it to unwind smoothly and evenly. The speed and direction of the uncoiling process can be controlled to match the specific requirements of the application.

- Q: Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q: What is the difference between hot rolled and cold rolled steel coils?

- The main difference between hot rolled and cold rolled steel coils lies in the manufacturing process and the resulting properties of the steel. Hot rolled steel coils are produced by heating the steel above its recrystallization temperature, which allows for greater malleability and ductility. This process also results in a rough surface finish. On the other hand, cold rolled steel coils are manufactured by rolling the steel at room temperature, resulting in a smoother and more refined surface finish. Cold rolling also increases the strength and hardness of the steel. Overall, hot rolled steel coils are more suitable for applications where flexibility and formability are important, while cold rolled steel coils are ideal for applications requiring high strength and a smooth surface finish.

- Q: How are steel coils used in the production of automotive frames?

- Steel coils are used in the production of automotive frames as they are rolled into sheets and then cut and shaped to form the necessary components of the frame. The coils provide the raw material that is strong, durable, and able to withstand the structural demands of the vehicle.

- Q: Can steel coils be coated with anti-counterfeit materials?

- Yes, steel coils can be coated with anti-counterfeit materials. These materials can include specialized coatings, holograms, unique serial numbers, or other security features that help prevent counterfeiting and ensure the authenticity of the steel coils.

- Q: Cooling bed generally a part of the steel rolling mills

- In the USA, a steel cooling bed is called a run-out table. It consists of a series of steel rolls. Each roll may be individually driven by an electric motor. DC motors are often used with parallel armatures connected to a common armature voltage control speed control unit. The roll speed is controlled to match the speed of the incoming sheet of steel so that the steel does not slide or skid on the surface of the rolls. Field trim resistors help to assure that the speed and torque of rolls is matched. A centering mechanism may be used to keep the steel in the center of the table. Water may be sprayed from the top and bottom to aid cooling. After an initial run out table, the strip of steel may be cut on-the-fly into individual sheets which pass to another table that is running slightly faster to separate the sheets. Alternatively, the steel may be coiled at the end of the table.

- Q: What are the different methods of forming steel coils into sheets?

- Steel coils can be formed into sheets using various methods, each having its own benefits and uses. 1. The most commonly employed technique is hot rolling. This involves heating the steel above its recrystallization temperature and passing it through rollers. The rollers apply pressure to reduce the thickness of the steel and elongate it into a sheet. Hot rolling yields smooth sheets suitable for a wide range of applications. 2. Cold rolling, on the other hand, does not require heating the steel. Instead, the steel coil is passed through rollers at room temperature. This process results in sheets with higher dimensional accuracy and a smoother surface finish. Cold-rolled sheets are ideal for applications requiring precise dimensions and a polished appearance, such as automotive body panels and appliances. 3. Annealing and pickling is a method that involves subjecting the steel coil to a heat treatment process called annealing, followed by pickling. Annealing entails heating the steel to a specific temperature and then slowly cooling it to relieve stress and enhance its mechanical properties. Pickling involves removing impurities and scale from the steel surface. These steps are typically performed before hot or cold rolling to ensure a high-quality end product. 4. Galvanizing is a process where steel sheets are coated with a layer of zinc to protect against corrosion. The steel coil is first cleaned and then immersed in molten zinc. The zinc adheres to the steel, forming a protective layer that prevents rust and corrosion. Galvanized sheets find common use in construction, automotive manufacturing, and electrical appliances. 5. Electro-galvanizing is similar to galvanizing, but instead of immersing the steel coil in molten zinc, an electric current is used to deposit zinc onto the steel surface. Electro-galvanizing provides similar corrosion resistance to traditional galvanizing but with a thinner coating. It is often favored for applications requiring thinner and more lightweight sheets. In conclusion, the formation of steel coils into sheets can be achieved through various methods such as hot rolling, cold rolling, annealing and pickling, galvanizing, and electro-galvanizing. Each method offers distinct advantages and is suitable for specific applications based on factors like surface finish, dimensional accuracy, and corrosion resistance.

- Q: What are the disadvantages of using steel coils?

- One disadvantage of using steel coils is their weight and size, which can make transportation and handling challenging. Additionally, steel coils are susceptible to corrosion, requiring regular maintenance and protective measures to prevent rusting. The production of steel coils also contributes to environmental pollution due to the energy-intensive manufacturing process. Lastly, the upfront cost of steel coils can be relatively high compared to other materials, which may not be suitable for budget-constrained projects.

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve assessing the extent of the damage, ensuring proper safety precautions are in place, and following industry best practices for handling and storing damaged coils. It is important to inspect the damaged coils for any potential hazards, such as sharp edges or protruding objects, and to use appropriate lifting equipment and protective gear when moving or transporting them. Additionally, damaged coils should be segregated from undamaged ones to prevent further deterioration and potential safety risks.

- Q: What are the common welding defects in steel coils?

- There are several common welding defects that can occur in steel coils during the welding process. These defects include: 1. Porosity: This is characterized by small holes or voids in the weld metal, which are caused by gas entrapment during the welding process. It can weaken the weld and make it more susceptible to corrosion. 2. Lack of fusion or incomplete penetration: This defect occurs when there is inadequate fusion between the base metal and the weld metal, or when the weld metal does not fully penetrate the joint. It can result in a weak or brittle weld. 3. Cracks: Cracks can occur in the weld metal or in the heat-affected zone (HAZ) of the base metal. They can be caused by factors such as high stress levels, improper cooling, or inadequate preheating. Cracks can significantly reduce the strength and integrity of the weld. 4. Undercutting: Undercutting is a groove or depression that forms at the toe of the weld due to excessive melting of the base metal. It weakens the weld and can lead to stress concentration and potential failure. 5. Excessive spatter: Spatter refers to the small droplets of molten metal that are expelled from the welding arc and can land on the surface of the steel coil. Excessive spatter can result in a rough or uneven surface finish and may require additional cleaning or grinding. To minimize these welding defects in steel coils, it is important to ensure proper weld preparation, including cleaning and removing any contaminants from the surface of the steel. Additionally, using the correct welding parameters, such as appropriate heat input and travel speed, can help to minimize defects. Regular inspection and quality control measures can also help to identify and address any defects before they become more serious issues.

Send your message to us

Prepainted Galvanized Steel Sheet in Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords