Pre-painted Galvanized Steel Coil Used for Industry with Our Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

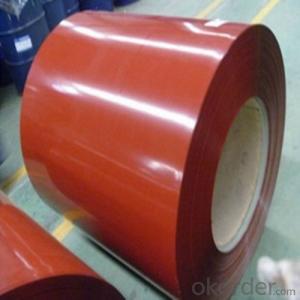

Pre-painted Galvanized Steel Coil Used for Industry

1.Structure of Pre-painted Galvanized Steel Coil Description

With GI as base metal, after pretreatement and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Painting steel isthe product based on the metal sheet, of which surface is finally installed ofthe plastic film(PVC, PE) IN addition to being firstly covered with the coatingand printed ink in. The coated layer of painting steel plate consists of chemicaland filming layer, primer coated layer, pattern printed layer and surfacecoated layer. The top and back coating shall generally be the weatherproofpaint, as well can be the application of the paint with special capabilitiessuch as stain-resistant, self cleaning capability, high thermal resistance,antistatic capability, sterilizing capability, finger-print prevention and etc.

With GI(aluzinc) asbase metal, after pretreatement(degrease and chemical treatment)and liquid dopewith several layers of color, then after firing and cooling, finally the platesteel is called pre-painted galvanized (aluzinc)steel. Pre-painted galvanized steelis good capable of decoration, molding, corrosion resistance. It generallydisplays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Pre-painted Galvanized Steel Coil Images

4. Pre-painted Galvanized Steel Coil Specification

Pre-painted Galvanized Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-275g/㎡

|

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Hi I was thinking about buying this knife, but i wasn't sure if it was good because it's stainless steel.

- This isn't really a question for this section, but I'm still happy to help out since I'm a big cutlery nerd as well. One thing to look out for when buying a knife is a lack of specifics on what steel is being used. High Carbon Stainless Steel doesn't tell you what the steel is, just what it MIGHT be. Chances are it's something along the lines of 420HC or 440A, both of which are softer steels. They aren't the worst steels around, but they are very quick to dull. You'd be better off looking at the Balisongs of Benchmade. They'll cost more, but you'll know that you're getting something made with quality materials and that won't break on you. And if it does break for some odd reason, Benchmade's warranty and customer service are both fantastic. Although if a more questionable knife is okay with you as long as the price isn't too high, then at least 420HC and 440A aren't too brittle and will take a decent edge even though they'll dull quickly. As for whether stainless steel is good for a knife or not, that depends on the type of stainless steel and what you're going to use the knife for. Many stainless steels are more brittle than a carbon steel, so high carbon stainless steels are a bit more likely to rust but a little tougher as well. In a butterfly knife, a steel like that is a good way to go, although the steels used by Benchmade, as I mentioned, are of a much better quality.

- Q: How are steel coils used in the production of electrical connectors?

- Steel coils are used in the production of electrical connectors as they provide a strong and durable core component. The coils are wound into the desired shape and size, and then further processed to create the necessary conductive pathways for electrical current. This ensures stability, strength, and efficient conductivity in the connectors, making them suitable for various electrical applications.

- Q: How are steel coils used in the manufacturing of household goods?

- Steel coils are commonly used in the manufacturing of household goods as they are shaped and processed into various components such as frames, springs, and supports. These coils provide strength, durability, and stability to items like furniture, appliances, and automotive parts, ensuring their longevity and functionality.

- Q: How are steel coils inspected for impact resistance using impact testers?

- Steel coils are inspected for impact resistance using impact testers, which are specially designed machines used to assess the ability of the steel coils to withstand impacts. The process involves subjecting the steel coils to controlled impacts and measuring the extent of deformation or damage caused by the impact. Firstly, the steel coils are securely placed on the impact tester, ensuring that they are in the correct position and orientation. The impact tester is equipped with a striking element, such as a pendulum or a falling weight, which is designed to deliver a specific amount of force upon impact. The striking element is carefully aligned with the steel coil to ensure accurate and consistent testing. Once everything is set up, the impact tester is activated, and the striking element is released to impact the steel coil. The force of the impact is carefully controlled and measured to ensure consistency across multiple tests. The impact tester records various parameters during the impact, including the force applied and the duration of the impact. After the impact, the steel coil is carefully examined for any visible deformation or damage. This can include checking for dents, cracks, or any other signs of structural compromise. The extent of the deformation or damage is recorded and compared to predetermined acceptance criteria to determine whether the steel coil passes or fails the impact resistance test. Impact testers can be equipped with various sensors and cameras to capture additional data during the testing process. High-speed cameras can be used to record the impact in slow motion, allowing for a detailed analysis of the coil's behavior during the impact. Strain gauges can be attached to the steel coil to measure the strain and stress experienced during the impact. Overall, the use of impact testers provides a reliable and standardized method for inspecting the impact resistance of steel coils. By subjecting the coils to controlled impacts and carefully measuring the extent of deformation or damage, manufacturers can ensure that their steel coils meet the required impact resistance standards for various applications.

- Q: What is the process of pickling and oiling steel coils?

- To ensure the quality and protection of steel coils, a series of steps are undertaken in the process of pickling and oiling. The first step involves pickling, wherein impurities and scale are removed from the surface of the steel coil. This is achieved by immersing the coil in an acid bath, such as hydrochloric acid or sulfuric acid, which effectively dissolves any oxides, rust, or contaminants present on the surface. This step is critical as it readies the steel for further processing and safeguards against potential defects or corrosion. Following pickling, the steel coils are rinsed with water to eliminate any residual acid and then dried. Once they are clean and dry, a layer of oil is applied to provide temporary corrosion protection and lubrication during subsequent handling and transport. The oil coating acts as a barrier, preventing rusting or oxidation before the steel undergoes further processing or is utilized in various applications. The oiling process can be executed through various methods. One common approach is to apply the oil using a roller or brush, ensuring an even coating across the entire surface of the coil. Alternatively, the coils can be passed through a bath or spray chamber where the oil is administered. The choice of oil depends on the specific requirements of the steel and its intended use, with options ranging from mineral oil and synthetic oils to specialized rust-preventive coatings. Once the oiling process is complete, the steel coils are typically stacked, wrapped, or packaged for storage or transportation. It is crucial to handle the coils with care to avoid damaging the oil coating and compromising the corrosion protection it provides. Overall, the pickling and oiling of steel coils are indispensable steps in the steel manufacturing process. They ensure the quality, cleanliness, and protection of the steel, thereby prolonging its lifespan and enhancing its performance in various applications.

- Q: I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- It's fine. Like .700 Nitro said, lead is a softer metal than steel. . BTW- Tom, grow up. I doubt you have ever been hunting in your life. What the he!! does someone's S.S number have to do with hunting? Nothing jack $$. Here's some advice for you- follow me around for a few days down here... It will cost you a little bit more than $15 per hour. Down here, a guy will actually realize that he as family jewels.

- Q: I know the law regarding selling steel core ammo, but is it possible to buy a steel core bullet and load it yourself?

- Please okorder / You're likely to find steel core ammunition from any of those manufacturers, and many more. Have fun... but steel core ammo is no more effective than lead ammunition, unless you're planning a crime spree and want to attempt to punch through a ballistic vest, and even that's not guaranteed.

- Q: which elements are alloyed to make stainless steel?A Fe, CB Fe, MnC Fe, NiD Fe, CrE Fe, Cr, Ni

- E. Stainless steel is mainly comprised of Cr and Ni. Steel is an alloy composed mainly of iron. On a side note, Carbon is not really in stainless steel and it is only less than .1%

- Q: Hi, does anyone know where i can find more about this topic ? fire resistant steels for structural applications. thanks

- Steel okorder /

- Q: Do you know of any movies that featured the steel drum?

- You okorder /.. If I can find any clips, I'll add them, but I'm sure that many movies in the proper settings (Trinidad, etc.) would have such music and/or show a group or at least a single performer. For example, Cool Running could be a possibility.

Send your message to us

Pre-painted Galvanized Steel Coil Used for Industry with Our Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords