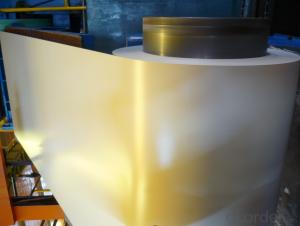

Prepainted Galvanized Steel Plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPECIFICATION:

Product name | Prepainted Galvanized Steel Plates |

Thickness | 0.3mm—1.2mm |

Width Length | 600mm—1250mm As client's requirement |

Zinc coating | 60g-225g |

Paint Thickness | Top:15-30um, back:5-10um |

Standard | ASTM A792, JIS G3321, JIS G3317, GB |

Material | SGCC/SGCH |

Base Plate | Hot dipped zinc coated steel sheet,hot dipped A-Z coated steel sheet |

Surface Paint | PE,PP |

Color Series | RAL color number series |

Equipment | Double coating double baking |

Packing | 1. standard seaworthy package : waterproof paper/iron sheet/steel strip/steel pallet 2. According to customers' requirements |

Coil Wgt. | 3Mt - 8Mt |

Coil ID | φ508mm,φ610mm |

Payment | T/T or L/C |

Min order | 50 tons |

Capacity | 4000Mt/week |

Delivery time | within 40 days upon receipt original L/C or advance payment |

APPLICATION:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers,

video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

- Q: Steel used to be made in the #92;Bessemer Converter, write about how steel making processes today produce better quality steel????

- Steel making today is a faster process as use Blast furnace which Coke Limestone Iron ore are fed into the top of the furnace. after these are fed in a exothermic happens and converts these ores into Iron. Iron is not strong enough to be used in thing this is formally known as pig iron. To convert Iron ore into steel it has to go to a process called the BOS Basic Oxygen Steel-making were oxygen is blown onto the iron ore for about 30 to 45 min and this then turns it into steel as all the impurities are taken out and this floats on top and known as slag and used for things such as road building. Once you have steel this is then pored into ladles and taken to the continuous caster and rolled into slabs, billets and bars and then cut off and rolled into a finished products and then taken to compniaes to be made into thins you see made out off metal such as skyscrapers. Hope this helps :o)

- Q: I bought a damascus steel knife. It will be used for display. Nothing like hunting/skinning. If It is just sitting around, will it rust? (assuming that it isn't getting wet) Thanks for the help.

- From that point of view the strength or edge-holding ability means very little. Specifically, the bushcraft knife is pattern welded steel. True damascus or Wootz steel is something you'll only find in museums and private collections. they stopped making it several hundred years ago. Despite what many people have claimed, Wootz damascus was inferior to modern tool steels in every respect. It was a brittle, dirty material.

- Q: What are the different methods of coil blanking for irregular shapes?

- There are several methods of coil blanking for irregular shapes. One common method is laser blanking, which uses a high-powered laser to cut the shape directly from the coil. This method is highly precise and allows for complex shapes to be cut with minimal waste. Another method is water jet blanking, which uses a high-pressure stream of water mixed with abrasive particles to cut the shape from the coil. Water jet blanking is often used for thicker materials or when the material being cut is sensitive to heat. Additionally, there is also die blanking, which involves the use of a die to stamp the shape out of the coil. This method is commonly used for larger production runs and can be automated for increased efficiency. Lastly, there is also plasma blanking, which uses a plasma torch to cut the shape from the coil. Plasma blanking is often used for thicker materials or when high cutting speeds are required. Overall, the choice of method for coil blanking irregular shapes depends on factors such as material thickness, shape complexity, production volume, and desired precision. Each method has its advantages and limitations, and selecting the most suitable method is crucial for achieving optimal results.

- Q: How are steel coils used in the production of metal containers?

- Steel coils are widely used in the production of metal containers due to their versatility and strength. The process of manufacturing metal containers typically involves several steps, and steel coils play a crucial role in each of these stages. Firstly, steel coils are used as the primary raw material in the production of metal containers. The coils are made of high-quality steel that is rolled into a continuous sheet, ensuring consistent thickness and durability. This sheet is then cut into specific widths and lengths according to the size requirements of the containers. Once the steel coils are cut into the desired dimensions, they are formed into the shape of the container using various techniques. One common method is called roll forming, where the steel coil is passed through a series of roll dies that progressively shape it into the desired container shape. This can be done to create containers of various sizes and designs, such as cans, drums, or even large industrial containers. After the initial forming process, the steel coils are further processed to enhance their strength and durability. This can involve heat treatment, where the coils are exposed to high temperatures to increase their hardness and resistance to wear and tear. Other processes like annealing and quenching may also be utilized to improve the steel's properties. Once the containers are formed and processed, they undergo additional fabrication steps such as welding or sealing to ensure their structural integrity. Steel coils are often used in these processes as well, as they provide a strong and reliable material to create sturdy seams and joints. Finally, the metal containers are finished by applying various coatings or treatments to protect them from rust, corrosion, or other environmental factors. Steel coils can be coated with materials such as paint, epoxy, or zinc to enhance their resistance to these elements, ensuring the longevity of the containers. In summary, steel coils are essential components in the production of metal containers. From being the primary raw material to being used in forming, processing, and finishing, steel coils provide the strength, durability, and versatility necessary for the manufacturing of reliable metal containers for various industries.

- Q: Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q: What are the different types of steel coil surface treatment options?

- There are several different types of steel coil surface treatment options available, each serving a specific purpose and providing various benefits. Some of the common surface treatment options include: 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc, which forms a protective zinc coating on the surface. Galvanizing provides excellent corrosion resistance and helps in extending the lifespan of the steel coil. 2. Electro-galvanizing: Similar to hot-dip galvanizing, but instead of immersing the coil in molten zinc, an electric current is used to deposit a thin layer of zinc onto the steel surface. Electro-galvanizing provides a smoother and thinner zinc coating, making it suitable for applications that require a more aesthetic finish. 3. Pre-painted or coated: Steel coils can be coated with a layer of paint or other protective coatings before they are formed into various products. This type of treatment provides additional protection against corrosion and enhances the aesthetic appearance of the steel coil. 4. Organic coating: Organic coatings are typically applied to steel coils to provide protection against corrosion and improve the overall durability of the product. These coatings can be in the form of epoxy, polyurethane, or other types of polymer-based materials. 5. Pickling: Pickling is a surface treatment process that involves removing impurities and scale from the steel coil by immersing it in an acid solution. This treatment helps in improving the adhesion of subsequent coatings and prepares the surface for further processing or finishing. 6. Oil coating: Steel coils can be coated with a thin layer of oil to protect the surface from oxidation and rust during storage or transportation. This coating is typically used as a temporary measure and is usually removed before further processing. 7. Shot blasting: Shot blasting involves propelling small metal particles at high velocity onto the steel coil surface. This process helps in removing rust, scale, and other contaminants, providing a clean and roughened surface for better adhesion of subsequent coatings. These are some of the commonly used steel coil surface treatment options. The choice of treatment depends on the specific requirements of the application, such as corrosion resistance, aesthetic appearance, or improved adhesion.

- Q: What other metal is used to make rings? My girlfriend is allergic to stainless steel, but she wears a silver/grayish color ring, but I'm not sure what metal it is. Any ideas? Thanks!

- In addition to silver, white gold, and titanium, it could be an alloy-a mix of a bunch of different metals. If she's allergic to stainless steel, though, she's probably allergic to nickel as well, which is often in metal alloys. Pewter is another silver-color metal that is sometimes used in rings. A pretty expensive silver-colored metal is platinum, but unless your girlfriend is rich or you gave it to her it's pretty unlikely she has a platinum ring. Your best bet would be to ask her if she knows what it's made of.

- Q: I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- It's fine. Like .700 Nitro said, lead is a softer metal than steel. . BTW- Tom, grow up. I doubt you have ever been hunting in your life. What the he!! does someone's S.S number have to do with hunting? Nothing jack $$. Here's some advice for you- follow me around for a few days down here... It will cost you a little bit more than $15 per hour. Down here, a guy will actually realize that he as family jewels.

- Q: y does 1095 steel on a katana weight about a pound less for the same amount than 1045? the 1095 is better right? but then why is 1045 steel more comenly used for practical use than 1095, even though i no its cheaper to use 1045 for tami mats. so is 1095 steel the better investment for buying and minor tami mat use?

- 1045 is a medium carbon steel is used when greater strength and hardness is desired than in the as rolled condition. Extreme size accuracy, straightness and concentricity combine to minimize wear in high speed applications. 1095 is a high carbon steel, but does not hold as sharp an edge. 1095 high carbon steel is harder and more durable than 440C stainless steel, but will rust much more easily. Stainless steel is more brittle than both 5160 and 1095 carbon steel, but is still very useful due to its resistance to rust and corrosion.

- Q: What are the weight ranges for steel coils?

- The weight ranges for steel coils can vary depending on the specific type and thickness of the steel. However, common weight ranges for steel coils typically range from a few hundred pounds to several thousand pounds.

Send your message to us

Prepainted Galvanized Steel Plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords