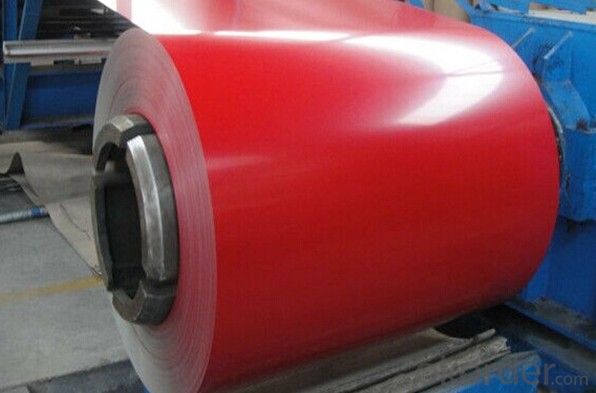

Prepainted galvanized steel coil 3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product | PPGI/PPGL |

|

|

Base material | Hot dipped galvanized steel |

Thickness | 0.12-0.80mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 60g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm Back painting: 6~10μm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

- Q: What are the different methods of testing steel coils for quality control?

- Steel coils undergo various methods for quality control testing to ensure they meet the necessary specifications and standards. These methods encompass visual inspection, dimensional measurement, hardness testing, tensile strength testing, chemical analysis, coating thickness measurement, surface roughness measurement, ultrasonic testing, and magnetic particle inspection. Visual inspection is the most fundamental technique, involving a thorough examination of the coils for surface defects like scratches, dents, or irregularities. This method enables the identification of visible defects in the material. Dimensional measurement, on the other hand, utilizes tools such as calipers, micrometers, or laser measuring devices to evaluate the dimensions of the steel coils. The measurements are compared against specified tolerances to ensure they meet the required standards. To assess the resistance of the steel coils to indentation or penetration, hardness testing is performed. This examination helps evaluate the material's strength and durability. Common hardness testing methods include Rockwell, Brinell, and Vickers hardness tests. Tensile strength testing measures the maximum tensile stress a steel coil can endure before breaking or deforming. This test helps determine the material's strength, elasticity, and compliance with the required specifications. Chemical analysis is crucial in testing the composition of the steel coils to verify the presence of specific elements in the desired amounts. This ensures that the coils are made from the correct grade of steel and comply with the required chemical composition standards. In cases where the steel coils have a protective coating, it is vital to measure the thickness of the coating. Non-destructive testing methods like magnetic induction or eddy current testing are typically employed for this purpose. The coating thickness is compared against the specified requirements to ensure it provides adequate protection. Surface roughness testing evaluates the smoothness or roughness of the steel coil's surface using instruments like profilometers or roughness testers. This testing method guarantees that the coils meet the required surface finish standards. Ultrasonic testing utilizes high-frequency sound waves to detect internal defects like cracks, voids, or inclusions within the steel coils. This non-destructive testing method provides valuable information about the structural integrity of the coil. Magnetic particle inspection is employed to identify surface and near-surface defects in steel coils. By applying magnetic particles to the surface and detecting any magnetic leakage caused by defects using magnetic sensors, this technique effectively detects cracks and other surface abnormalities. By combining these testing methods, manufacturers ensure that the steel coils produced meet the necessary quality standards and are suitable for their intended applications.

- Q: Can i use steel shot in a remington 870 wingmaster full choke 30 inch barrel. the shotgun is in great shape and about 20 or 25 years old probably. thank you. the steel shot i have got is 12 gauge 2 3/4 in 1550 velocity 1 1/16 oz 2 shot winchester xpert high velocity steel shot

- The biggest problem is the FULL choke on the end of the barrel. Steel pellets are harder than lead, so they find it hard to squeeze through the tight full choke. If you do it, you WILL either bulge or crack the muzzle end of the barrel. That is a fact. Newer model 870 shotguns with RemChokes can fire steel, but you have to use a lead MODIFIED choke to send a full pattern down range. Again, for the same reason I mentioned earlier - that the steel does not deform and squeeze itself through the tighter chokes as well. See photo link below at what your barrel will look like after a box of steel shot.

- Q: How are steel coils used in the manufacturing of packaging materials?

- Steel coils are used in the manufacturing of packaging materials as they provide strength and stability to the packaging structure. They are commonly used as a core material for packaging tubes, enabling them to withstand heavy loads and prevent deformation. Additionally, steel coils are utilized in the production of steel straps, which are widely used for securing packages and pallets, ensuring safe transportation and storage of goods.

- Q: How are steel coils used in the production of automotive body panels?

- Steel coils are used in the production of automotive body panels by being processed and formed into the desired shape and size. The coils are typically unwound and fed through a series of machines that stamp, press, or roll the steel into the required panel shape. This process allows for efficient mass production of body panels, ensuring strength, durability, and precision in the final product.

- Q: How are steel coils used in the manufacturing industry?

- Steel coils are widely used in the manufacturing industry as they are essential for various applications such as automotive, construction, appliances, and machinery. These coils are commonly used to produce various metal components and parts, including sheet metal, pipes, tubes, and wire. The coils are unwound and fed into different machines and processes, where they are shaped, cut, stamped, or welded to create the desired products. Due to their durability, strength, and malleability, steel coils are highly valued for their versatility and play a crucial role in the manufacturing industry.

- Q: Which one would be stronger? And should damascus steel be tempered?Thank You

- Damascus steel is in history books only,no body knows its composition.THey just named a modern steel as Damascus steel

- Q: I'm analysing horse stirrups and would like to know the disadvantages to stainless steel? - thanks

- For horse stirrups the main disadvantage to stainless steel is the manufacturing cost. Stainless steels tend to work harden, and are subject to their own peculiar forms of corrosion, but I see little implication to either of these factors when used as a stirrup iron or a safety latch. Stainless steel is also subject to self welding, or galling, this would be of no concern for the irons, but could result in the pivot of the safety latch freezing (I have never known anyone to ride with the safety latch closed, however).

- Q: How are steel coils distributed globally?

- Steel coils are distributed globally through a well-established supply chain network. Manufacturers typically ship steel coils to various locations worldwide through ocean freight or rail transportation. These coils are then distributed to customers, including construction companies, automotive manufacturers, and other industries, through local distributors or directly from steel service centers. Additionally, international trade and partnerships play a significant role in the global distribution of steel coils, ensuring a steady supply to meet market demands.

- Q: How are steel coils used in the production of solar panels?

- Steel coils are not directly used in the production of solar panels. However, steel is typically used in the manufacturing of the structural frames and mounting systems for solar panels. These frames and mounting systems provide support and stability to the solar panels, ensuring their proper installation and long-term durability.

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve assessing the extent of the damage, ensuring proper safety precautions are in place, and following industry best practices for handling and storing damaged coils. It is important to inspect the damaged coils for any potential hazards, such as sharp edges or protruding objects, and to use appropriate lifting equipment and protective gear when moving or transporting them. Additionally, damaged coils should be segregated from undamaged ones to prevent further deterioration and potential safety risks.

Send your message to us

Prepainted galvanized steel coil 3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords