Prepainted Galvanized Corrugated Steel Sheet - New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized Corrugated Steel Sheet - New Style:

With GI as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized Corrugated Steel Sheet - New Style:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

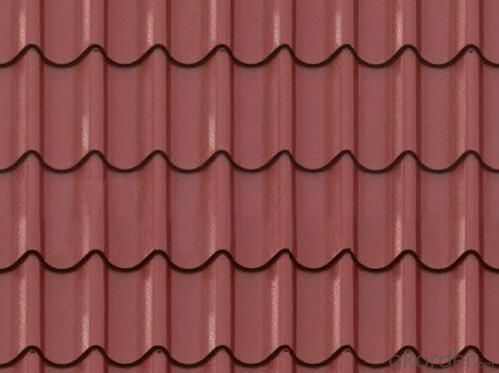

3.Prepainted Galvanized Corrugated Steel Sheet - New Style Images

4.Prepainted Galvanized Corrugated Steel Sheet - New Style Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized Corrugated Steel Sheet - New Style

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your MOQ?

Normally our MOQ is 25mt per size ,but it is up to different size.

- Q: Are steel sheets suitable for decorative applications?

- Indeed, decorative applications can benefit from the suitability of steel sheets. The versatility, durability, and aesthetic appeal of steel sheets allow for their use in a wide range of decorative purposes. They can be easily shaped, sized, and patterned to fit different needs. Steel sheets offer various possibilities for creating decorative elements such as wall panels, room dividers, ceiling tiles, and facades. They can also be utilized for decorative accents like trims, moldings, and decorative screens. The sleek and reflective surface of steel sheets adds a touch of modernity and elegance to any space. Furthermore, steel sheets can be enhanced with different finishes and coatings to further enhance their decorative properties. These options include paints, powder coatings, patinas, and even specialized coatings like faux rust or metallic finishes. With these choices, steel sheets can complement any interior or exterior decor style, opening up a wide range of design possibilities. Additionally, steel sheets are highly durable and long-lasting, making them suitable for both indoor and outdoor decorative applications. They are resistant to corrosion, fire, and extreme weather conditions, ensuring that the decorative elements made from steel sheets maintain their appearance and functionality over time. To sum up, steel sheets are an excellent choice for decorative applications. Their versatility, durability, and aesthetic appeal make them a perfect option for creating visually appealing and long-lasting decorative elements in various settings.

- Q: Q195 galvanized steel plate, is it hot or cold?

- Cold rolling mill for rolling power, low efficiency, and the rolling process in order to eliminate work hardening and annealing, so the cost is higher, but the cold rolled steel surface bright, good quality, can be directly used for processing products, it is ten points wide application of cold rolled steel plate.

- Q: What are the different types of finishes available for steel sheets?

- There are several types of finishes available for steel sheets, including mill finish, brushed finish, mirror finish, galvanized finish, and painted finish.

- Q: How do steel sheets perform in terms of corrosion resistance?

- Steel sheets possess good corrosion resistance in general, particularly when they are coated with protective layers like zinc or alloys. The corrosion resistance of steel sheets relies on the steel's composition and quality, as well as the environment in which they are employed. Stainless steel sheets, for instance, demonstrate remarkable resistance against corrosion due to the presence of chromium and other alloying elements. These sheets prove highly effective in environments with elevated humidity, exposure to saltwater, or acidic conditions. However, in aggressive environments, uncoated or low-alloy steel sheets may be vulnerable to rust and corrosion. Regular maintenance, such as the application of protective coatings or the use of corrosion inhibitors, can enhance the corrosion resistance of steel sheets and extend their lifespan.

- Q: How thick can steel sheets be?

- Steel sheets can vary in thickness depending on their intended use, but they can typically range from as thin as 0.4 millimeters to as thick as 25 millimeters or more.

- Q: What are the common sizes of steel sheets available?

- Steel sheets are available in a variety of sizes to meet the diverse needs of different industries and applications. The common sizes of steel sheets can vary depending on the manufacturer and the specific requirements of the customer. However, there are some standard sizes that are widely available in the market. The most common sizes of steel sheets include: 1. 4 feet by 8 feet: This is one of the most popular sizes and is widely used in construction, manufacturing, and automotive industries. It provides a large surface area for various applications, including roofing, siding, and fabrication. 2. 4 feet by 10 feet: This size is similar to the 4 feet by 8 feet sheets but offers a larger surface area, making it suitable for larger projects that require more material. 3. 5 feet by 10 feet: This size provides an even larger surface area than the 4 feet by 10 feet sheets, making it ideal for industrial applications that require extensive coverage. 4. 6 feet by 12 feet: This is a larger size that is commonly used in heavy-duty applications, such as shipbuilding, construction of large structures, and industrial machinery. It's important to note that these are just some of the common sizes available, and there are many other sizes offered by manufacturers to cater to specific requirements. Additionally, steel sheets can also be custom-cut to fit specific dimensions, allowing for greater flexibility and tailoring to individual project needs.

- Q: Are steel sheets suitable for playground equipment?

- Indeed, playground equipment can be made using steel sheets. Steel is a robust and enduring substance that can endure extensive use, offering a secure playing environment for children. Steel sheets are versatile and can be utilized to build an array of playground equipment, ranging from slides to climbing structures and swing sets. Moreover, steel is impervious to weather conditions, rendering it an ideal selection for outdoor playgrounds. The material can be effortlessly molded and formed into various designs, providing room for innovation and personalization in playground equipment. All in all, steel sheets are a dependable and enduring choice for playground equipment, guaranteeing children's safety and enjoyment.

- Q: What is the average bending radius for steel sheets?

- The average bending radius for steel sheets can vary depending on the thickness and type of steel being used. However, a common range for the average bending radius of steel sheets is between 0.5 to 2 times the thickness of the sheet.

- Q: STCC what's the quality of the cold rolled steel sheet?

- Cold rolled steel: iron sheet thin, generally zero millimeters, galvanized; steel plate thickness, generally more than 3mm, there are also 1mm

- Q: What is the average weight of a steel sheet per square meter?

- The average weight of a steel sheet per square meter depends on the thickness and type of steel, but it typically ranges from 7.85 to 8.05 kilograms per square meter.

Send your message to us

Prepainted Galvanized Corrugated Steel Sheet - New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords