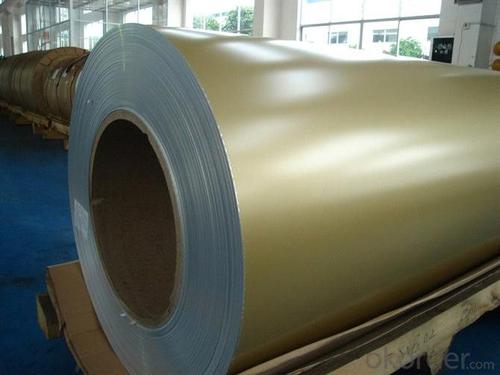

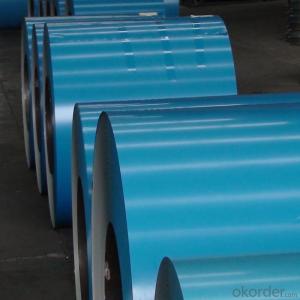

Prepainted Galvalume Rolled Coil for Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Galvalume Rolled Coil

Description of Prepainted Galvalume Rolled Coil

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Galvalume Rolled Coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Galvalume Rolled Coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Prepainted Prepainted Galvalume Rolled Coil

Specifications of Prepainted Galvalume Rolled Coil

Structure | |||

Item | Thickness | Type | Feature |

Laminated film | 50μm | Polyethylene | Protecting from scratchs and contamination(option) |

Top coat | 20μm | Polyester Fluorine | Chemical resistance and formability |

Primer coat | 5μm | Polyester | Workability, corrosion resistance and adhesion to the primer coating |

Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

Substrate | 0.2mm-1.2mm | GI.GL,AL | GI.GL,AL |

Back coat | 5±2μm | Epoxy | Corrosion resistance and adhesion to the substrate |

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the common quality control measures for steel coils?

- To ensure the performance and reliability of steel coils, several common quality control measures are implemented. These measures play a crucial role in upholding the overall quality of the coils and ensuring their compliance with the necessary standards and specifications. To begin with, dimensional checks are conducted to verify that the steel coils possess the correct thickness, width, and length. Deviations from the specified dimensions can significantly impact the coils' functionality and usability, making this check of utmost importance. Following that, visual inspections are carried out to identify any surface defects or imperfections such as scratches, dents, or corrosion. These inspections aid in identifying potential issues that could compromise the structural integrity of the coils or affect their aesthetic appearance. Moreover, mechanical property tests are performed to assess the strength, hardness, and other mechanical characteristics of the steel coils. These tests provide valuable insights into the coils' performance and durability under different conditions and loads. An essential quality control measure for steel coils is the analysis of their chemical composition. This involves scrutinizing the steel's composition, including the presence of any impurities or elements that may impact its properties. It ensures that the coils are made from the correct grade of steel and meet the required chemical specifications. Coating inspections also play a vital role in quality control. When steel coils are coated with protective layers, it is imperative to examine the adhesion, thickness, and uniformity of these coatings. This examination ensures that the coils have sufficient protection against corrosion and other environmental factors. Lastly, various non-destructive testing methods, such as ultrasonic testing, magnetic particle inspection, or eddy current testing, are employed to detect any internal defects or abnormalities in the steel coils. These tests enable the identification of issues like cracks, inclusions, or discontinuities that may not be visible through visual inspection alone. In conclusion, the quality control measures for steel coils consist of dimensional checks, visual inspections, mechanical property tests, chemical composition analysis, coating inspections, and non-destructive testing. These measures are vital in maintaining the quality and reliability of steel coils, guaranteeing their compliance with the required standards, and meeting customer expectations.

- Q: What are the environmental benefits of using steel coils?

- Using steel coils offers several environmental advantages. To begin with, steel is a highly recyclable material. Steel coils can be easily recycled and transformed into new steel products, reducing the necessity for mining and extracting raw materials. Recycling steel also consumes less energy than producing it from scratch, resulting in lower greenhouse gas emissions and a smaller carbon footprint. Moreover, steel is renowned for its durability and longevity. When employed in construction or manufacturing, steel coils can endure for decades without compromising their structural integrity. This reduces the need for frequent replacements, which, in turn, decreases resource consumption and the energy required for production. Additionally, steel exhibits exceptional resistance to corrosion and weathering, making it an ideal choice for outdoor applications. Its ability to withstand harsh environmental conditions means that steel coils can maintain their functionality for extended periods, reducing waste generation and the environmental impacts associated with replacing damaged or deteriorated materials. Lastly, steel is an adaptable material that finds utility in a wide range of industries and applications. Its versatility allows for efficient resource utilization, as steel coils can be easily adjusted and customized to meet specific project requirements. This adaptability also enables the use of steel in sustainable building designs, such as energy-efficient structures or green buildings that incorporate renewable energy systems. In conclusion, the use of steel coils brings about environmental benefits related to their recyclability, durability, resistance to corrosion, and versatility. Opting for steel coils in various applications contributes to resource conservation, reduced carbon emissions, and a more sustainable future.

- Q: What are the factors to consider when selecting steel coils for a specific application?

- When selecting steel coils for a specific application, there are several factors that need to be considered. These factors include the type of application, the required strength and durability, the desired aesthetic appearance, the budget, and any specific industry standards or regulations that need to be met. Firstly, it is important to determine the type of application for which the steel coils will be used. Different applications may require different types of steel with varying properties. For example, if the coils will be used in structural construction, high-strength steel with excellent structural integrity may be required. On the other hand, if the coils will be used in automotive manufacturing, steel with good formability and weldability may be more suitable. The required strength and durability is another crucial factor to consider. This includes factors such as the load-bearing capacity, resistance to corrosion, and ability to withstand extreme temperatures or environmental conditions. The steel coils must be able to withstand the specific stresses and strains that will be placed upon them in the intended application. The desired aesthetic appearance is also important, especially in applications where the steel coils will be visible. Factors such as the surface finish, color, and texture of the steel coils may need to be considered. This is particularly relevant in industries such as architecture or interior design, where the visual appeal of the steel is a key consideration. Budgetary constraints should also be taken into account when selecting steel coils. Different grades and types of steel can vary significantly in price. It is important to find a balance between the desired properties and the available budget. Sometimes, it may be necessary to compromise on certain factors in order to meet budgetary constraints. Lastly, any specific industry standards or regulations should be considered when selecting steel coils. Certain industries, such as aerospace or automotive, may have strict requirements for the materials used in their products. In such cases, it is crucial to ensure that the selected steel coils meet all necessary standards and regulations. In conclusion, when selecting steel coils for a specific application, factors such as the type of application, required strength and durability, desired aesthetic appearance, budget, and industry standards or regulations should all be carefully considered. By taking these factors into account, one can make an informed decision and choose the most suitable steel coils for their specific application.

- Q: Do any tour players use steel shafted woods? And are there any real advantages to having steel shafted woods? I have only played with one person to use steel shafted woods, he tells me thats because he cant hit it straight with graphite, however he is a very short hitter.

- Graphite shafts are generally better for the amateur golfer. Graphite shafts are more forgiving than stell shafts. With graphite shafts, it is easier to get the ball in the air, and keep your ball trajectory always with good height. For SOME above average golfers and tour professionals, steel shafted woods find their way into their bags. This is because steel shafts have the ability of being more precise in terms of direction. However, to hit steel shafted woods, you need a lot of power and a slightly faster than normal tempo. Point is, if your a golfer that plays this sport for the leisure, or don't want to be stressed, take the graphite shafts. But if you're a single-digit handicapper, and feel you're physically fit ALL THE TIME, then go ahead and try the steel shafts.

- Q: How are steel coils processed for heat treatment?

- Steel coils are typically processed for heat treatment by first being uncoiled and then cleaned to remove any dirt or scale. The coils are then heated to a specific temperature, which is determined based on the desired properties of the steel. This temperature is maintained for a specific period of time to allow for the desired transformation of the steel's microstructure. After the heat treatment process is complete, the coils are cooled either slowly or rapidly, depending on the desired properties. This allows the steel to be hardened or softened as required. Finally, the coils are recoiled and prepared for further processing or shipment.

- Q: How are steel coils used in the production of heating and cooling systems?

- Steel coils are used in the production of heating and cooling systems as they serve as the primary component for heat transfer. These coils are designed to efficiently transfer heat or cool air, allowing for the effective regulation of temperature in heating and cooling systems.

- Q: What are the different types of steel coil recoiling methods?

- There are three main types of steel coil recoiling methods: slit edge recoiling, mill edge recoiling, and oscillated recoiling.

- Q: Can we construct a barn using steel and will it be a durable one?

- sure , steel barns are all over the place...the common brand of steel buildings around here are Butler Buildings...

- Q: Some stainless steel products are as shiny as chrome. Can all/most stainless steel be polished to a chrome like luster.

- The nickel and chromium content do have some effect on shine. But mostly they effect the corrosive and rust resistance property's of the stainless steel. 300 series stainless steel such as 304e or 316e will not rust like 400 series 416e eventually will. All types of stainless steel can achieve a bright shine. The key is using jewelers rouge and the correct buffing wheel. Avoid scotchbrite if you want shine. It will clean your stainless steel but it will not shine it the way you want. Miketyson26 (certified tig welder)

- Q: What are the common methods of transporting steel coils?

- Depending on factors such as coil size, weight, destination, and specific handling requirements, there are various common methods for transporting steel coils. These methods include: 1. Short-distance transportation: For short distances, steel coils are often transported using flatbed trucks. These trucks have a flat trailer bed that allows for easy loading and unloading of the coils. To prevent movement during transit, the coils are secured and strapped down. 2. Long-distance transportation: Rail transport is commonly preferred for longer distances due to its cost-effectiveness and efficiency. Specially designed railcars, known as coil cars or gondola cars, are used to securely hold the coils in place. This method is particularly advantageous for large quantities of steel coils. 3. International or long-distance transport: Shipping by sea is a common method for transporting steel coils internationally or over long distances. The coils are loaded into specialized shipping containers with internal cradles to prevent movement and damage during transit. These containers are then loaded onto cargo ships. 4. Waterway transportation: In regions with navigable waterways, barges can be used to transport steel coils. Similar to ocean freight, the coils are loaded into specially designed containers or barges with cradles to secure them during transport. Barge transport offers an economical and environmentally friendly option, especially for inland waterway transportation. 5. Combined transportation: In certain cases, a combination of different transportation modes, known as intermodal transport, may be used. For instance, steel coils can be initially transported by truck and then loaded onto railcars for long-distance transport. This approach allows for the optimization of cost and efficiency by utilizing the advantages of different transportation modes. It's important to note that the specific method of transporting steel coils can vary based on various factors, including coil size, weight, destination, and any specific handling requirements.

Send your message to us

Prepainted Galvalume Rolled Coil for Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords