China 3003 Aluminum Coil for Decoration Materials Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

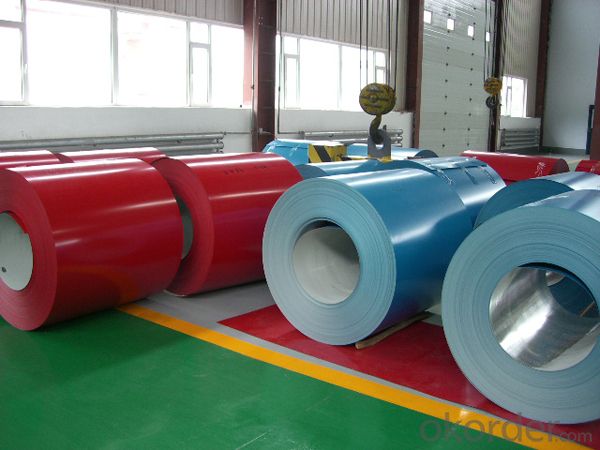

Prepainted Aluminium Coil For Decoration Materials Production

Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

Thickness | 0.1mm to 6mm |

Width | 20mm to 3300mm |

Coil weight | 100kgs to 6 tons depends on actual requirement |

Core material | Aluminum or paper |

Coil inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

Appplication | construction, roofing, decoration, lamping etc |

Package | eye to wall or eye to the wall for aluminum coil with wood pallet (wooded case also available) |

Characteristics

1) Excellent weather-proof durability

2) Anti-ultraviolet

3) Glass curtain wall frame

4) Interior decoration

5) Elevator decoration

6) Signs, nameplate, bags making.

7) Automobile parts material

8) Office and Household appliances: HVAC equipments

9) The consumer electronics: mobile phones, digital cameras, MP3 .etc.

Coating varieties

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What’s the coating of top side?

--A: PVDF and PE coating

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: I bought some drain opener as a source of sodium hydroxide and it has little silvery balls in it which I believe are aluminium. How can I separate the two substances with minimal loss of the sodium hydroxide? I don't care about the aluminium.

- Trust me. Its not worth salvaging the hydroxide. Aluminum hydroxide is unbelievably stable and that means you probably won't be able to salvage the hydroxide without doing electrolysis or something difficult like that. That's like trying to obtain hydroxide from methanol CH3OH. Oh yea you can make methanol quite easily from a halomethane by reacting it with a hydroxide of some kind. But you will not be able to remove that hydroxide at all without neutralizing it with an acid. Hydroxides are bloody awful leaving groups. That oxygen is really glued on to that carbon well. You have to really destabilize that methanol to remove that hydroxide. Same with the aluminum hydroxide. Very stable and strong bond.

- Q: What are the common cutting and shaping methods for aluminum coils?

- There are several common cutting and shaping methods for aluminum coils, depending on the desired outcome and application. One of the most common methods is shearing, which involves cutting the aluminum coil with a sharp blade. Shearing is ideal for straight cuts and is often used for applications that require precise dimensions, such as manufacturing automotive parts or construction materials. Another method is slitting, which involves cutting the aluminum coil into narrower strips. Slitting is commonly used in industries such as packaging, where thin strips of aluminum are needed to create products like food packaging or aluminum foil. For more complex shapes, such as curves or bends, a method called press brake forming is often used. In this process, the aluminum coil is placed in a press brake machine and bent into the desired shape using a punch and die. Press brake forming is commonly used in industries like aerospace or architectural design, where intricate shapes are required. Additionally, laser cutting is a popular method for cutting aluminum coils. Laser cutting uses a high-powered laser beam to cut through the aluminum, allowing for precise and intricate cuts. This method is often used in industries like signage or electronics, where detailed designs are necessary. Overall, the common cutting and shaping methods for aluminum coils include shearing, slitting, press brake forming, and laser cutting. These methods offer various options for manufacturers to shape aluminum coils according to their specific needs and requirements.

- Q: What is the price range of aluminum coils?

- Aluminum coil prices can fluctuate depending on a range of factors including thickness, width, alloy type, and market conditions. Typically, the price range for aluminum coils can begin at $1 per pound for thinner gauge coils and can rise to $3 per pound or more for thicker gauge coils or specific alloys. It is crucial to understand that these prices are estimated and subject to change based on market demand, availability, and other economic influences. To obtain accurate and current pricing information, it is advised to reach out to suppliers or refer to market research reports.

- Q: How are aluminum coils cut to size?

- Aluminum coils are typically cut to size using specialized coil slitting machines. These machines have rotating circular blades that make precise cuts along the length of the coil. The coil is fed through the machine, and the blades cut the aluminum into the desired width. The cut pieces are then collected and further processed or used for various applications.

- Q: Are aluminum coils suitable for insulation applications?

- Yes, aluminum coils are suitable for insulation applications. Aluminum is a popular choice for insulation due to its excellent thermal conductivity properties. It effectively reflects heat and cold, making it an efficient material for insulating applications. Additionally, aluminum coils are lightweight, durable, and resistant to corrosion, making them suitable for various insulation needs. They can be easily installed and provide long-lasting insulation performance. Overall, aluminum coils are an excellent choice for insulation applications.

- Q: What is the difference between hot rolled and cold rolled aluminum coils?

- The main difference between hot rolled and cold rolled aluminum coils lies in the manufacturing process. Hot rolled aluminum coils are produced at temperatures above the recrystallization temperature, resulting in a more malleable and ductile product. Cold rolled aluminum coils, on the other hand, are processed at room temperature, making them stronger and more rigid. This difference in processing also affects the surface finish and dimensional accuracy of the coils.

- Q: Are aluminum coils suitable for heat exchanger applications?

- Yes, aluminum coils are suitable for heat exchanger applications. Aluminum has excellent thermal conductivity and corrosion resistance properties, making it an ideal choice for heat transfer in various industries such as HVAC, automotive, and refrigeration. Additionally, aluminum coils are lightweight and cost-effective, making them a popular option for heat exchangers.

- Q: can you use the Brasso Aluminum cleaner on aluminum wheels? i have a set of mickey thompson classic II wheels and i want to polish them up. they have water spots that are almost impossible to clean. how can i shine them up to make them almost like chrome wheels? i heard brasso works great but then i heard it damages the wheels?

- Brasso On Aluminum

- Q: Can aluminum coils be used in signage applications?

- Indeed, signage applications can make use of aluminum coils. The durability, corrosion resistance, and lightweight characteristics of aluminum render it a favored material for signage purposes. Aluminum can effortlessly take on different shapes and sizes, making it suitable for a wide range of signage types, including outdoor signs, billboards, trade show displays, and more. Furthermore, aluminum coils boast exceptional weather resistance, guaranteeing the preservation of the signage's integrity and vibrancy even in harsh environmental circumstances. The versatility and longevity of aluminum establish it as the preferred option for signage applications across diverse industries.

- Q: This question asks about potential health hazards linked to the use of aluminum coils in culinary settings.

- <p>There are some concerns about using aluminum cookware due to the potential for aluminum to leach into food, especially at high temperatures or in acidic environments. While the human body needs small amounts of aluminum, excessive intake can be harmful. It has been linked to neurological disorders, although the evidence is not conclusive. Most health organizations, including the FDA, consider aluminum cookware safe for general use. However, for those who are concerned, alternatives like stainless steel, cast iron, or non-stick coatings are available. It's always best to follow manufacturer's guidelines and avoid using aluminum cookware for acidic or highly acidic foods to minimize any potential risk.</p>

Send your message to us

China 3003 Aluminum Coil for Decoration Materials Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords