Premix ARG Chopped Strand

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

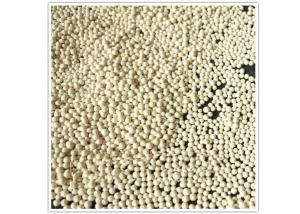

Fiberglass chopped strand(Zro2 16.5) is designed for use in dry mix systems for moulding into a GRC component to prevent crackHUIERJIE AR GLASSFIBRE CHOPPED STRAND is a high integrity AR glassfibre chopped strand designed for use in dry mix systems or other premixing processes for subsequent moulding into a GRC component.

This kind of chopped strand has a sizing system optimised for abrasion resistance and strand integrity during blending with dry materials .The low-tex strand permits efficient reinforcement at low dosages .It is particularly suited to the preparation of pre-bagged mixes of special mortars or renders .It may also be used in the manufacture by precasting of standard GRC components.

Example:ARC15-98-12mmL(H)

AR: Alkali Resistant

C: Continuous fibre

15 : Filament diameter

98: Tex of strand

12mm: strand length available

L: ZrO2 content 14.5%

H: ZrO2 content 16.7%

Properties

Good liquidity and integrity

Excellent alkali resistant and durability

been approved by Sheffied University,UK.

Technical Characteristics

Tex of strand(tex) | Sizing content(%) | Moisture(%) |

JC/T572-2002 | JC/T572-2002 | JC/T572-2002 |

98±10 | 1.6±0.2 | ≤0.2 |

Products available

HUIERJIE AR GLASSFIBRE CHOPPED STRAND are packed in vacuum polythene bag. Each polythene bag is identified by an individual label. HUIERJIE chopped strands are white coloured but an orange or blue colour is used on labels to aid identification.

Product | Strand length available(mm) | Packing specification (mm) | Net weight(kg) |

ARC15-98-XmmL(H) | 6、8、12、16 | 550×550×65 | 15 |

Pallet Packaging

Each pallet has 14 levels ,4 bags /level,totally 56 polythene bag;

The complete pallet is enclosed in polythene and identified with two labels.

Product | Pallet | |||

Length(mm) | width(mm) | Height(mm) | Net weight(kg) | |

ARC15-98-XmmL(H) | 1130 | 1130 | 1100 | 840 |

Shipment

For sea transport, a maximum of 20 pallets (on two levels) may be loaded in a 20 foot container, total net weight is approximately 16 tonnes.

Road vehicle: Up to 18 pallets, total net weight 14.4 tonnes.

.

Quality

HUIERJIE AR GLASSFIBRE CHOPPED STRAND are manufactured under a Quality Management System approved to ISO 9001:2000.

- Q: I was told I could use rubber cement in place of liquid masking film (Frisket) for masking off areas in my watercolors. Is it gentle enough that it won't rip the watercolor paper when removed?

- No. That is, yes, you can use it, and it may not rip top quality papers. But rubber cement is a very bad choice if you want your art to last. It is harmful to cheaper papers and to all work over time. That's why Frisket, and other fine art masking fluids were developed. So if you care about the long-term preservation of your art, do not use rubber cement. For student quality work, or something you plan to toss once you're finished, fine.

- Q: I'm investigating the relative differences in stress of cement when expanding and contracting, I understand that cement can take significantly more stress and strain when contracting rather then expanding however -Does this line have the same gradient (ie youngs modulus) as that when Cement is expanding

- I'm investigating the relative differences in stress of cement when expanding and contracting, I understand that cement can take significantly more stress and strain when contracting rather then expanding however -Does this line have the same gradient (ie youngs modulus) as that when Cement is expanding To cause cement to contract, a force is applied toward the surface of the cement. A building is supported by a cement foundation. The weight of the building is pushing down on the top surface of the cement, and the ground under the foundation is pushing up on the bottom surface of the cement. The cement foundation is composed of rocks and mortar. The mortar is the adhesive which bonds the rocks to each other. The weight of house is attempting compress the rocks and mortar. The compressive strength of the rocks is very high, so the rocks do not significantly. If a concrete beam is used to lift a large weight, tension force is attempting to expand the cement. The tensile strength of the mortar is very low, so the rocks separate from each other as the bond between the rocks and mortar, glue, break.

- Q: It's gray and turns all hard, where do they get the ingredients and how come there never seems to be a short supply of it?

- Cement should not be confused with concrete. The term cement refers only to the dry powder substance used to bind the aggregate materials of concrete. Upon the addition of water and/or additives the cement mixture is referred to as concrete, especially if aggregates have been added.

- Q: it's all in a 5 gallon bucket and the cement is level with the top. I plan on moving in the next 6 months so the pole needs to be mobile.

- If what you are asking is how long before I can move the bucket and pole? The answer is about two days after it was installed. Cement setting or curing is a chemical reaction and the majority of it is done within two days of mixing and pouring. It will reach approximately 85 to 90% of total cure in about one week, but for it to be totally cured could take years. Ten year old cement is harder than eight year old cement which is harder than four year old which is harder that one year old, etc. In the remodeling business, old concrete stairs and porches are a pain in the *** to remove. Most of the time if we thought that they were more than ten years old we would call in the back hoe to tear them out, other wise we used sledge hammers.

- Q: Ones cement concrete is set and solid, it is as hard as rock? How it happens?Are pebles or cource sand in it helps? Or is it cement powder that becomes hard?

- When you mix Portland Cement, sand, gravel, water, and in some cases, an entraining agent, the mixture undergoes a chemical reaction due to the cement called hydration. This mixture hardens into what is called concrete. Gravel and sand in the concrete are what are called aggregates. The cement is what binds the sand and the gravel together. The gravel and the sand are what give the concrete its compressive strength (sometimes you add prestressed steel to give it better strength). If you simply used Portland Cement, it would fall apart easily. The sand is present to fill the voids, or empty spaces, between the gravel rocks. An entraining agent is often added (a liquid poured from a bottle) to remove the air from the mixture, resulting in a higher quality concrete.

- Q: it's square shaped 12x12 with a grill. Right next to the deck and with a view of the ocean. The house is grey-blue

- Red cement patio? Did you paint it or use red-colored cement? Bravo! Since you prefer brightly colored additions to your life, go hog wild and buy fluorescent furniture to lounge around in. Your living quarters then might qualify as a historic lighthouse and you will be know far and wide as the keepers.

- Q: how many bags of cement will i have to buy if i wanted to fill a 5 gallon bucket?i am going to fill it half full, put a friend of mines' Christmas present into it, and then cover the rest.I worked in concrete for two years so i know how to set it all up, but we generally dealt with trucks of concrete, not buckets.so. how many bags? or how many pounds?

- A five gallon bucket can hold .45 cubic feet of concrete when mixed with water. In other words, one 60 pound bag of pre-mix or an equivalent Portland Cement/rock and sand mix. At .45 cubic feet the bucket may overflow and/or be too deep to properly mix, but I do it all the time for difficult access pours of small quantities.

- Q: The cement board now has holes, tons of marks, glue, bad wallpaper you name it. Can I place drywall over it in order paint it? I plan to replace the tile from the waist down but on the upper wall I want to paint. Any tips are appreciated.

- Fir it out as necessary and re drywall it with green board drywall. It will look much better and be right.

- Q: no tile in shower/bath surroundPosted by erik0619 on January 6th, 2006 07:42 AMPost Reply | Watch this PostI am renovating my bathroom. I don't want to put up new tile in the shower. Can I just use cement board and some type of paint so that the walls and the shower walls in the bath all look the same? I've already put up the cement board and taped off the seams what do I use in the seams? What type of paint or coating can take constant showering?

- get ins chool

- Q: Pls Provide Top 10 interview question about cement marketing?Raj_bajaj2050@yahoo.in

- Cement Marketing

Send your message to us

Premix ARG Chopped Strand

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords