Pre-painted Rolled Steel Coil for Construction Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

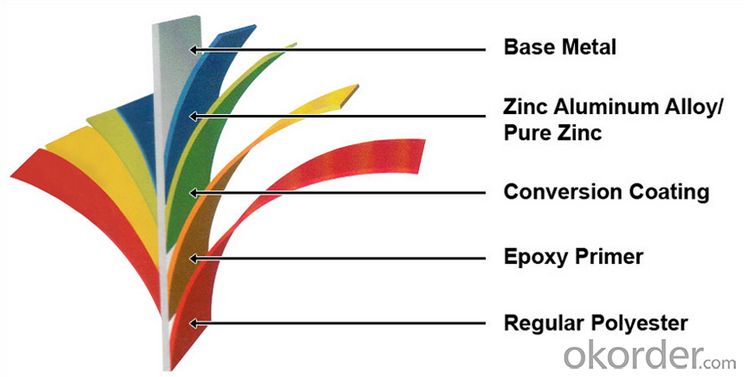

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: did bible stated that steel is coming from outer space. i mean meteor rocks that enter our earth sistem contains the minerals iron.

- If you are using either an NAB or RSV translation of the Bible, steel is only mentioned once in the Bible. Compare Nahum 2:4 (NAB) and Sirach 31:26 (RSV). There is no reference of an outer space in the Bible. Furnace is mentioned in Sirach. It takes a lot of energy to mix Iron and Carbon to produce steel. The alloy can only be produced in the furnace at an extremely high temperature.

- Q: like building steel beams. i'm pretty sure with a sawzall.

- Most I-beams are manufactured in a factory by rolling the red hot steel billet through several sets of rolls till the I-beam takes it's final shape. All we normally do to a factory stock I-beam is cut it to length, trim the ends, punch out the mounting holes and or weld on shear tabs. Some I-beams like tapered ones are built from scratch in the shop using plate steel. In fabricating in the shop, a plasma cutter or cutting torch is used along with a hydraulic plate shear. Repairs during erection, usually a cutting torch because you are several stories in the air. If the beam has to be taken to the ground, still a cutting torch because on a job site power availability is poor to connect a plasma cutter. Wingman

- Q: What are the common methods of testing the durability of steel coils?

- Common methods of testing the durability of steel coils include tension tests, impact tests, bending tests, hardness tests, and corrosion tests.

- Q: Are steel coils used in construction?

- Yes, steel coils are commonly used in construction. They are often used in the manufacturing of structural components, such as beams, columns, and trusses, as well as in the construction of metal buildings and infrastructure projects. Steel coils provide strength, durability, and versatility to various construction applications.

- Q: My neighbor who has an older model mustang installed a steel clutch in it and has blown 4 transmissions as a result.Can any mechanic explain why a steel clutch would kill transmissions? What other modifications would the car need in order to prevent this?

- First of all it's not really a steel clutch..it is called a sintered iron clutch disk... a sintered iron clutch has a very aggressive amount of friction and is generally only used in racing application because of this...also it is ushually a non sprung disk. all of these factors = a very abrupt ingagement of the clutch which will shock the driveline very badly...say he's making 400hp and has really sticky tires..there is bound to be a weak link between the engine and the tires, in a factory driveline this would probably have been the clutch(it would slip) but since he has upgraded it he has now found the next weekest llink..in this case the transmission, he either needs to look into a beefier box or not launch the car so hard.

- Q: What are the pros and cons to selecting a graphite shaft sand wedge over steel shaft?

- Graphite Shaft Wedges

- Q: How are steel coils used in the production of doors and windows?

- Steel coils are vital components in the production of doors and windows due to their strength and versatility. These coils are typically made from high-quality steel and are used in various stages of the manufacturing process. Firstly, steel coils are used to create the frame of the doors and windows. The coils are unrolled and cut into specific lengths, depending on the desired dimensions of the frame. The steel is then bent and shaped into the required frame design, ensuring that it is strong and durable. Next, the coils are used to produce the panels or glass holders for the doors and windows. The steel is cut and formed into the desired shape, and then it is either welded or attached to the frame. This ensures that the doors and windows have a sturdy structure and can handle the weight and pressure of the glass or panels. Additionally, steel coils are also used to create the hinges and other hardware components of the doors and windows. The coils are cut and shaped into the necessary parts, ensuring that they are strong enough to support the movement and functionality of the doors and windows. Furthermore, steel coils can be used for decorative purposes. They can be embossed or coated with different finishes to enhance the appearance of the doors and windows. This allows for a wide range of design options, enabling manufacturers to create doors and windows that suit various architectural styles and preferences. In summary, steel coils play a significant role in the production of doors and windows. They are used to create the frame, panels, hinges, and other hardware components, ensuring strength, durability, and functionality. Additionally, they can be used for decorative purposes, allowing for customization and aesthetic appeal.

- Q: How are steel coils used in the production of automotive structures?

- Various methods involve the usage of steel coils in the production of automotive structures. To begin with, these coils serve as the primary material for manufacturing car bodies and frames. Typically composed of high-strength steel, known for its durability and crashworthiness, these coils undergo processing and forming to create different automotive components such as panels, doors, roofs, and pillars. Moreover, steel coils are also utilized in the creation of various structural components within an automobile. For instance, they contribute to the fabrication of suspension systems, chassis, and other vital parts that provide stability, strength, and support to the vehicle. Steel coils frequently find application in the production of structural beams, reinforcement bars, and other load-bearing elements that ensure the overall strength and safety of the vehicle. Furthermore, steel coils play a significant role in the manufacturing of automotive parts that require precise shaping and forming processes. These coils are fed into stamping presses, where they undergo a series of operations including cutting, bending, and shaping to produce intricate parts such as brackets. The versatility of steel enables the production of complex automotive structures with exceptional accuracy and precision. Additionally, steel coils are crucial in the production of automotive exhaust systems. Typically composed of stainless steel, which exhibits excellent resistance to corrosion and high temperatures, these coils are formed and welded into exhaust pipes, mufflers, and catalytic converters, guaranteeing the durability and longevity of these critical components. In conclusion, the utilization of steel coils is essential in the production of automotive structures. They are employed in the creation of car bodies, frames, suspension systems, chassis, and other structural components. Steel coils also play a vital role in the manufacturing of precise and intricate automotive parts, as well as exhaust systems. Overall, the presence of steel coils contributes significantly to the strength, safety, and longevity of automotive structures.

- Q: I beat fallout 3 and i downloaded broken steel expansion. I have no idea how to get to broken steel in other words i do not know how to start playing it.

- after-wards you will have to sit through the end movie, which I felt was longer than the original, then the broken steel part will start, which I wont ruin. If your still having problems, go into your DLC and delete broken steel, and re-install it.

- Q: What is the use for spring steel that take advantage of its unique properties?

- The primary use is for springs. It can be deflected to a large extent by applying a force it will return to its original shape when the force is removed. The force/displacement relationship tends to be a constant. A lesser use is to use spring steel wire as a vibrating string on a stringed instrument.

Send your message to us

Pre-painted Rolled Steel Coil for Construction Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords