Pre-painted Rolled Coil for Roofing Construtions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

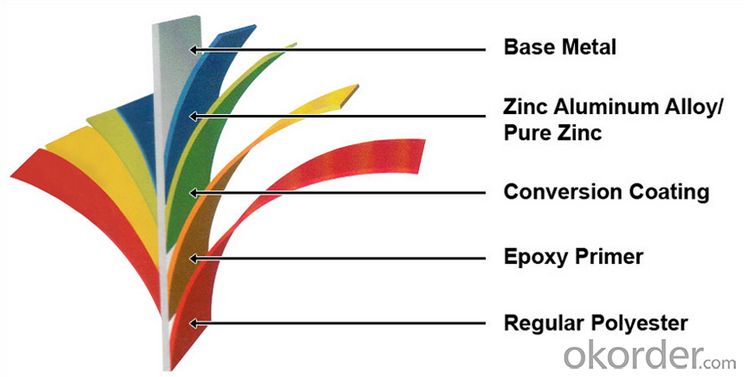

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the HVAC industry?

- Steel coils are commonly used in the HVAC industry for heat transfer purposes. They are typically used in air conditioning and refrigeration systems to transfer heat between the refrigerant and the surrounding air. The coils are designed to efficiently absorb or release thermal energy, allowing for effective cooling or heating.

- Q: I live in the Black Hills and I need to re-side my cottage. I like the look of vinyl. I've heard pros and cons about both steel and vinyl. Is steel really that easy to dent? It just doesn't look as 'clean' as vinyl. Also what 3 color combos do you like? My cottage has shutters.

- Steel okorder and pick your colors from there. just choose a setting and clickdrag your colors

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These techniques help identify surface cracks, internal flaws, irregularities in thickness, and other defects, ensuring the quality and integrity of the steel coils.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- Not a chance. Stresses that are strong enough to crack solid steel would snap JB weld like a matchstick! JB is NOT a substitute for actual welding. Steel is more than 20 times stronger; or in other words, JB is 20 times weaker than the steel in your chair. JB is good for applications where the parts to be joined aren't constantly going to be under stress. For wood or plastics it works OK, for steel, not so much. Your best bet is to take the chair to a professional welding shop. If they want to charge you more than $15-$20; go somewhere else, they could weld that in less than a minute.

- Q: What are the common industry standards for steel coils?

- The common industry standards for steel coils include specifications related to dimensions, weight, chemical composition, mechanical properties, and surface finish. These standards are often set by organizations such as the American Society for Testing and Materials (ASTM), International Organization for Standardization (ISO), and the Steel Industry Associations.

- Q: What are the different types of steel coil packaging materials?

- Some common types of steel coil packaging materials include wooden crates, steel frames, plastic strapping, stretch wrap, and steel bands.

- Q: Does a magnet stick to galvinied steel?

- yes it does. The steel below the galvanized coating still has a relative high carbon content and magnets stick to it. Magnets do not stick to stainless steel very well though. There is a weak attraction there. If I recall correctly this is due to the relatively low carbon content and the higher content of chromium.

- Q: Does anyone have any idea where I could get a necklace that has the British Steel by Judas Priest logo?

- Bristish Steel...ROCKS!!! Ebay is a good suggestion but if its something custom like that you could always bring in a drawing or picture to a jeweler and they can source it for you ;) I did something similar and the jeweler actually made it custom for me.... just a suggestion :) Good Luck!

- Q: steel can be used to do?

- I also know that jawaysteel this company, they're really good

- Q: What are the applications of steel coils in automotive manufacturing?

- Steel coils have a wide range of applications in automotive manufacturing due to their unique properties and characteristics. They are commonly used in various parts and components of vehicles, offering numerous benefits and contributing to the overall performance, safety, and reliability of automobiles. One of the primary applications of steel coils in automotive manufacturing is in the production of body panels. Steel coils are used to create the outer body structure of vehicles, including doors, hoods, fenders, and roofs. The high strength and durability of steel make it an ideal material for these components, as it provides protection against impacts and enhances the overall structural integrity of the vehicle. Steel coils are also used in the manufacturing of automotive chassis and frames. The strong and rigid nature of steel makes it an excellent choice for these critical components, as it can withstand heavy loads and provide stability to the vehicle. Steel coils ensure that the chassis and frames have the necessary strength and stiffness to support the weight of the vehicle and withstand the forces experienced during driving. Moreover, steel coils are utilized in the production of various suspension and steering components, such as springs, stabilizer bars, and control arms. These components require high strength and resistance to fatigue, as they are subjected to constant stress and vibrations. Steel coils provide the necessary toughness and flexibility to these parts, ensuring smooth and controlled vehicle handling. In addition, steel coils are used in the manufacturing of engine parts and exhaust systems. The high-temperature resistance and corrosion resistance of steel make it an ideal material for these applications. Steel coils are formed into various shapes, such as tubes and pipes, and used to create exhaust manifolds, catalytic converters, and mufflers. They play a crucial role in improving the performance and efficiency of the engine, as well as reducing harmful emissions. Overall, steel coils are vital in automotive manufacturing due to their strength, durability, and versatility. They are used in the production of body panels, chassis, suspension components, engine parts, and exhaust systems. The use of steel coils in these applications ensures that vehicles are safe, reliable, and perform optimally, making them an indispensable material in the automotive industry.

Send your message to us

Pre-painted Rolled Coil for Roofing Construtions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords