Pre-Painted Galvanized Steel Sheet or Coil in Prime Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

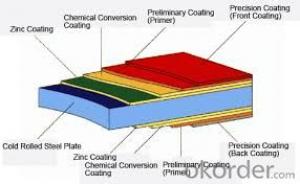

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How do steel coils compare to other materials in terms of cost?

- Steel coils are generally more cost-effective compared to other materials due to their durability, versatility, and widespread availability in the market.

- Q: What are the common applications of cold-rolled steel coils?

- Cold-rolled steel coils have a wide range of common applications in various industries due to their exceptional qualities. One of the most common applications is in the automotive industry, where cold-rolled steel coils are used to manufacture car parts such as body panels, chassis components, and structural reinforcements. The high strength and excellent formability of cold-rolled steel make it ideal for these applications. Another common application is in the construction industry, where cold-rolled steel coils are used to fabricate structural elements for buildings and infrastructure. Cold-rolled steel is often used to make beams, columns, and other load-bearing components due to its superior strength and durability. Cold-rolled steel coils are also widely used in the manufacturing of appliances and consumer goods. They are commonly used to create the outer shells of refrigerators, washing machines, and ovens. The smooth and consistent surface finish of cold-rolled steel makes it perfect for these applications, as it provides an aesthetically pleasing appearance. Additionally, cold-rolled steel coils find applications in the electrical industry. They are used to produce electrical enclosures, transformers, and various other components due to their excellent electrical conductivity and magnetic properties. Overall, the common applications of cold-rolled steel coils span multiple industries, including automotive, construction, appliances, and electrical. The versatility, strength, formability, and aesthetic appeal of cold-rolled steel make it a preferred choice for many manufacturers in various sectors.

- Q: This is my first time buying new strings for my violin and I’ve narrowed it down to two choice based on reviews and cost. The only difference I can see between the strings is that one has a solid steel core and the other has a synthetic core. What are the pros and cons of each type of core?

- Play okorder /

- Q: Can solution annealing be done on carbon and low alloy steels. please give an explanatory answer.

- No. Carbon steel has two different crystal structures, FCC and BCC , depending on the temperature. when you heat steel up and then quench it, it locks the crystal structure into the BCC form. this makes it hard. whereas precipitation hardened austentic stainlesses remain BCC regardless of the temp, so the hardness change is not a function of thermally induced strain. you can anneal carbon steel but the thermal profile is closer to the precipitation profile of PH stainlesses than it is to the Solution annealing profile.

- Q: hello guys. im totally new to this metalwork things. i need to do it for my project. i need to join stainless steel wires to build some kind of structure (eiffel tow. for example).i already have the wire and the torch. now the question is: where do i get silver solder? is it expensive? and what is flux for? is it necessary? what does it do? is it expensive?thank u for ur time guys! :)

- Silver Solder is more expensive than lead/tin solder as it contains silver. It also melts at a much higher temperature. You require special Flux designed for stainless steel and silver solder. Cost of Silver Solder and Flux will depend on the quality, quantity, and where you are located. Prices vary from area to area especially country to country. Instructions: 1: Clean all surfaces to be soldered with solvent and a wire brush to remove all grease, corrosion or dirt. 2: Apply a coating of flux to the stainless steel parts you are connecting. If you are soldering brass or copper parts to the stainless steel, tin them first by heating them and applying a thin coat of solder to the area that connects to the stainless steel. 3: Hold your parts together with wire or clamps. Make sure the surfaces fit flush. Silver solder will not fill gaps. 4: Heat the parts with a torch until the solder flows onto the joint. When the parts are hot enough, the solder will instantly turn to liquid when it touches the metals, then it will flow into the joint. If it does not do this, keep heating the metal until it does, but do not heat the solder directly. Only allow the hot metal to melt the solder. 5: Remove the torch and solder as soon as a sufficient amount of solder melts onto the joint. You don't need much, and a glob can look ugly. 6: Allow the metal to cool before touching or cleaning it. You can dunk it in water to cool it faster.

- Q: How are steel coils used in the production of metal panels?

- Steel coils are used in the production of metal panels as the primary raw material. These coils are fed into a roll forming machine, where they are uncoiled, flattened, and then shaped into the desired panel profiles. This process allows for efficient and continuous production of metal panels with consistent quality and strength.

- Q: What are the common coil widths and thickness combinations available for steel coils?

- The common coil widths and thickness combinations available for steel coils vary depending on the specific requirements and industry standards. However, there are some standard sizes that are commonly available in the market. For coil widths, the most common standard sizes range from 600mm to 2000mm. These widths are widely used in various industries such as automotive, construction, and manufacturing. However, custom widths are also available to meet specific project needs. As for the thickness combinations, steel coils are typically available in a range of thicknesses. The most common thicknesses for steel coils are between 0.4mm and 3mm. However, thicker or thinner options are available depending on the specific application. It is important to note that these standard sizes and thickness combinations may vary based on the specific steel grade, manufacturing process, and the supplier's capabilities. It is always recommended to discuss the required specifications with the supplier or manufacturer to ensure the availability of the desired coil widths and thickness combinations.

- Q: I have two theories, which one's correct?My book says that steel is made up of 98% iron and 2% carbon.98% of iron's molar mass (55.85 g/mol) is 54.733.2% of carbon's molar mass (12.01 g/mol) is .2402.If you add them up that gives you that steel has a molar mass of 54.97 g/mol.However, steel's chemical formula is Fe(3)CThat would make it's molar mass 179.56 g/mol.( Because 3(55.85) + 12.01 = 179.56 )Which one is correct?

- Steel is an alloy - a mixture not a compound; it doesn't have a chemical formula. Only elements and compounds have molecular weights, not mixtures that aren't composed of a uniform molecule, so neither answer is correct.

- Q: How are steel coils processed and shaped into various products?

- Steel coils are processed and shaped into various products through a series of manufacturing processes. First, the steel coil is uncoiled and cleaned to remove any impurities. Then, it goes through a process called leveling, where the coil is flattened and straightened. Next, the steel is cut into the desired length or shape, using techniques like shearing or slitting. After that, it may undergo additional processes such as forming, bending, or rolling to give it the desired shape. Finally, the steel is often treated with coatings or finishes to enhance its durability and appearance.

- Q: I have heard that heating the steel and applying oil will help with corrosion, and will give that aged look. I would like to know finishes available without painting. thanks

- No, I don't think the oil will do what you want. I have heated and quenched metal in oil several times (to harden it) and it did not give a finish to steel. I have heard of heating steel to a high temperature (red) and putting powdered sulfur on it, it will make a black finish. BUT, sulfur stinks and you would not do this indoors. And I don't know what the results would be like for indoor use. At the hardware store, you can find something like POR (paint on rust), a brand name of rust neutralizer. There are others. You spray it on (or paint) and it will turn rust into a glossy black material. Other than that, I think paint is your best option. Check out the new finishes they have now, if you haven't checked, they have come a long way. If you let them dry completely (in the sun) the spray can finishes are very durable. Good luck! Ooops, I forgot about gun finishes. Yes, some are blue, you might be thinking of that, but that is only if you put several coats on. One coat might do it. Plus, there are other colors, such as black (see the parkerizing link on the list). Here is a good company, they can be lots of help, too.

Send your message to us

Pre-Painted Galvanized Steel Sheet or Coil in Prime Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords