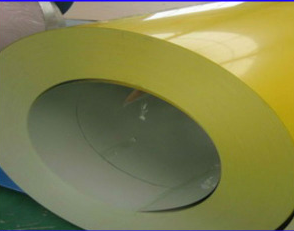

Pre-Painted Galvanized Steel Sheet/Coil with Prime Quality Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I am wondering what the highest quality steel is used in handgun production.

- The first answer was correct. The type of steel used in most blued handguns is the highest. After that I prefer stainless. Then the Scandium framed pistols.

- Q: What are the different coil packaging materials used for steel coils?

- Different materials are used for packaging steel coils, each with its own unique properties and benefits. Some of the most commonly used materials are as follows: 1. Stretch film is a flexible material that tightly wraps around the coil, providing protection against dust, moisture, and scratches. 2. Steel strapping is a strong and durable option that ensures the coils remain tightly bound during transportation or storage, thanks to its high tensile strength and resistance to breakage. 3. Plastic strapping, on the other hand, is a lightweight and cost-effective alternative to steel strapping. It offers good shock absorption and is resistant to rust and corrosion, making it suitable for smaller or lighter steel coils. 4. Paperboard is an environmentally friendly packaging material that provides a protective layer against dust and minor impacts. It also allows for slight breathability to prevent moisture buildup. 5. Wooden crates are commonly used for large or heavy steel coils, as they offer sturdy support and protection during handling, transportation, or storage. 6. Corrugated cardboard is a versatile and lightweight material suitable for smaller steel coils. It provides cushioning and protection against minor impacts, and it is easily recyclable. The choice of packaging material for steel coils depends on factors such as coil size and weight, transportation requirements, and the desired level of protection. Each material has its own advantages and should be selected based on the specific needs of the steel coil packaging.

- Q: hi to every one I need to konw moer about steel and iron industry (process) thank you in advance for your intresting

- Primary Steel Making first Iron ore Coke Lime stone are mined and then took to the steel plant and put in the top off a blast furnace and sinks down to the bottom off the blast furnace and turns into molten iron. Once this process has been done it is then transferred to a BOS (Basic Oxygen Steel Making) this is then poured from a ladle into the BOS and a Lance is inserted into the BOS and pure oxygen is blown into the BOS for about 30 min and turns into steel.

- Q: I want to start getting throwing knives and i was wondering what material is best for quality, but still cheap. I also saw some 440 stainless steel knives that i liked and wanted to know if the material was good

- Good steel ain't cheap, cheap steel ain't good... If you're just starting out (practicing anyways), I would be less concerned about the material and more concerned about the style and shape of the blade to gain consistency in your technique... When you start getting proficient for competitions and such... then I'd start investigating steel grades... Anyways, here's a summary from the wiki: Type 440—a higher grade of cutlery steel, with more carbon, allowing for much better edge retention when properly heat-treated. It can be hardened to approximately Rockwell 58 hardness, making it one of the hardest stainless steels. Due to its toughness and relatively low cost, most display-only and replica swords or knives are made of 440 stainless. Available in four grades: 440A, 440B, 440C, and the uncommon 440F (free machinable). 440A, having the least amount of carbon in it, is the most stain-resistant; 440C, having the most, is the strongest and is usually considered more desirable in knifemaking than 440A, except for diving or other salt-water applications.

- Q: What are the different types of steel coil surface treatments for indoor applications?

- There are several different types of steel coil surface treatments that are suitable for indoor applications. These treatments are designed to enhance the appearance, durability, and performance of the steel coil in various indoor environments. Some of the common surface treatments for indoor applications include: 1. Galvanized Coating: This is one of the most popular surface treatments for indoor applications. Galvanizing involves applying a layer of zinc to the steel coil, which provides excellent corrosion resistance and protects the steel from environmental elements. 2. Pre-painted Coating: Pre-painting the steel coil with a specific color or finish is another common surface treatment for indoor applications. This coating not only improves the aesthetics of the steel, but also provides additional protection against corrosion and wear. 3. Powder Coating: Powder coating is a process where a dry powder is electrostatically applied to the steel coil and then cured under heat. This treatment creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder coating is available in a wide range of colors and textures, making it a versatile choice for indoor applications. 4. Vinyl Coating: Vinyl coating is a type of surface treatment that involves applying a layer of PVC (polyvinyl chloride) to the steel coil. This coating provides excellent chemical resistance and protects the steel from moisture, abrasion, and UV radiation. Vinyl coating is commonly used in indoor applications where chemical exposure or moisture resistance is a concern. 5. Laminated Coating: Laminating the steel coil involves bonding a thin layer of plastic or other material to the surface of the steel. This treatment enhances the appearance of the steel and provides additional protection against scratches, stains, and fading. Laminated coatings are available in various colors and patterns, making them suitable for indoor applications where aesthetics is a priority. It is important to consider the specific requirements of the indoor application when choosing a steel coil surface treatment. Factors such as corrosion resistance, durability, aesthetics, and budget should be taken into account to ensure the best possible performance and longevity of the steel coil in indoor environments.

- Q: How are steel coils used in the production of pipes and tubes?

- Steel coils are used in the production of pipes and tubes by being fed into a pipe or tube mill, where they are unraveled, formed, and welded together to create the desired size and shape of the pipe or tube.

- Q: Are steel coils susceptible to damage during storage or transportation?

- Yes, steel coils are susceptible to damage during storage or transportation. Factors such as mishandling, improper stacking, exposure to moisture or extreme temperatures, and inadequate packaging can lead to dents, scratches, corrosion, and even deformation of the coils. Adequate precautions and secure packaging are necessary to minimize the risk of damage during storage or transportation.

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- The 2 objects will have the same size and shape. Therefore they will have the same air resistance. So the heavier object (the sheet of paper) will reach the ground first.

- Q: How are steel coils inspected for surface defects using non-destructive testing methods?

- Steel coils are inspected for surface defects using non-destructive testing methods such as visual inspection, magnetic particle inspection, and eddy current testing. Visual inspection involves closely examining the coil's surface for any visible defects or abnormalities. Magnetic particle inspection is used to detect surface cracks and defects by applying a magnetic field and then applying iron particles that reveal any magnetic leakage caused by defects. Eddy current testing is employed to detect surface cracks and defects by inducing an alternating current in a coil that creates a magnetic field, and any changes in the field caused by defects are detected. These non-destructive testing methods help ensure the quality and integrity of steel coils without causing any damage.

- Q: No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- Scott, there are 3 types of materials: elements, compounds, and mixtures. Compounds are covalently bonded elements. Compounds and elements are both considered 'pure' substances. Mixtures are not bonded in any fashion. So a steel mixture can have varying amounts of iron, carbon, silica,molybdenum, etc., giving the steel the desired properties (strength, rigidity, rust resistance, etc.).

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil with Prime Quality Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords