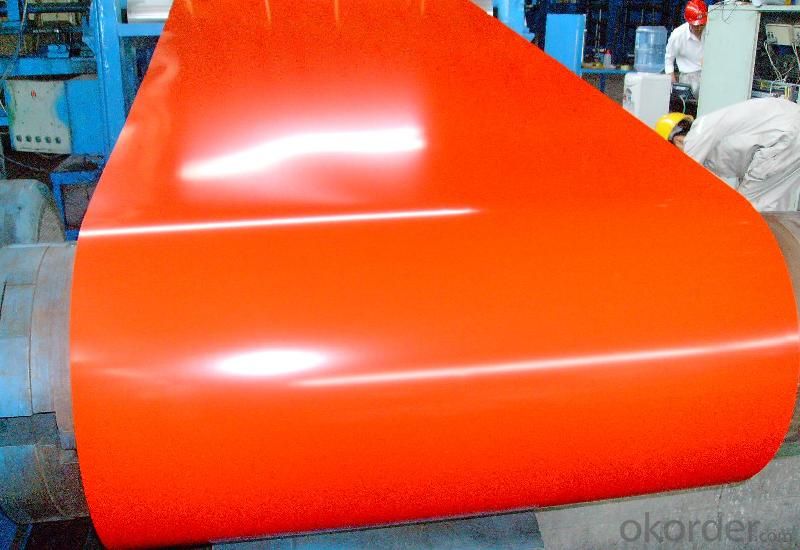

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price in Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• High strength

• Good capable of decoration

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

6.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

- Q: What are the common size limitations for steel coil production?

- The common size limitations for steel coil production can vary depending on several factors such as the type of steel being used, the manufacturing process, and the equipment available. However, there are some general size limitations that are commonly observed in the industry. One of the primary constraints is the width of the steel coil. The width of the coil is typically limited by the size of the rolling mill or the slitting equipment used for production. Standard widths for steel coil production range from around 600 millimeters (23.6 inches) to 2,000 millimeters (78.7 inches). However, widths outside of this range can also be achieved through specialized equipment and processes. Another limitation is the thickness of the steel coil. This can be influenced by the type of steel, the intended application, and the manufacturing capabilities. Common thicknesses for steel coils range from 0.15 millimeters (0.006 inches) to 6 millimeters (0.236 inches). Thicker or thinner coils can be produced, but they may require specialized equipment and processes. The weight of the steel coil is another important consideration. The maximum weight of a steel coil is typically determined by the capacity of the production and handling equipment, as well as transportation limitations. Standard coil weights range from a few hundred kilograms to several tons. However, it is possible to produce coils that exceed these limits by using larger equipment or dividing the coil into multiple smaller coils. In addition to width, thickness, and weight, there may also be limitations on the length of the steel coil. This can be influenced by factors such as the size of the production line, the handling and transportation capabilities, and customer requirements. Standard coil lengths typically range from a few meters to several tens of meters. However, longer coils can also be produced by using specialized equipment and processes. It is important to note that these size limitations are not fixed and can vary depending on the specific requirements of a project or customer. Manufacturers often work closely with customers to determine the optimal size limitations for their steel coil production, ensuring that the final product meets the desired specifications.

- Q: What are the main factors that affect the formability of steel coils?

- The main factors that affect the formability of steel coils include the composition and microstructure of the steel, the thickness and width of the coils, the presence of any impurities or defects in the material, the temperature and speed of the forming process, and the type of equipment and tooling used for forming.

- Q: Ok, I need two negative facts about steel wheels and two for aluminum wheels. im designing a wheel for a project in design and draw for production class. Also if you find a web site that you got the info from plz refrence it i need to write down the source of the info, but if you can't its ok. Thanks

- Negative facts for steel wheels: (1) Not as many style choices as aluminum. (2) Rust easily even when painted or powder coated, due to rock chips. (3) Heaver than aluminum, as far as fuel economy. Negative facts for aluminum wheels: (1) More sensitive to proper torquing of lug nuts. IE torque must be checked more often. (2) Susceptible to impact damage from road hazards much more than steel. (3) Need constant attention to prevent oxidation. Are these what you are looking for? I hope so. Wingman

- Q: What are the different types of steel coil coatings for heat resistance?

- Heat resistance is achieved through the use of different types of steel coil coatings. These coatings are designed specifically to safeguard the steel surface, preventing it from deteriorating or oxidizing under high temperatures. Organic coatings, such as epoxy, polyester, or polyurethane, are commonly used. They form a protective barrier against heat and prevent the steel from corroding or oxidizing. Organic coatings are typically employed in situations where moderate heat resistance is necessary. Another option is inorganic coatings, made from ceramic or metallic materials. These coatings offer excellent heat resistance and can endure extremely high temperatures. Industries like automotive, aerospace, and power generation frequently utilize inorganic coatings, as their components are exposed to intense heat. Specialized coatings are also available to meet specific heat resistance requirements. Silicone coatings, for instance, exhibit exceptional heat resistance and can withstand temperatures reaching 600°C (1112°F). They find common use in applications like exhaust systems, ovens, and industrial furnaces. Some steel coil coatings may also incorporate additives or fillers to enhance their heat resistance properties. These additions improve the coating's ability to withstand high temperatures and provide superior protection against heat-related issues. In conclusion, a range of steel coil coatings is available for heat resistance, including organic coatings, inorganic coatings, and specialized coatings. The choice of coating depends on the specific heat resistance requirements of the application. Factors such as temperature range, duration of exposure, and environmental conditions must be taken into account when selecting the appropriate coating.

- Q: I'm doing a commercial for chemistry and I need to know any kind of chemistry dealing with Callaway Big Bertha Irons. I know they are stainless steel but any more info would help out! Thank you! :)

- Stainless steel is a mixture of metals, each metal is included in order to make up for each others weaknesses. Each metal is included due to a property that is benificial in some way, for instance Chromium is included because it makes the stainless steel 'stainless'. In chemistry a mixture of metals, stainless steel, is called an alloy.

- Q: How are steel coils inspected for flatness variations?

- Steel coils are inspected for flatness variations using various methods such as visual inspection, measurement techniques, and automated systems. Visual inspection involves trained personnel visually inspecting the coil's surface for any irregularities or deviations from flatness. Measurement techniques involve using precision instruments such as straight edges, feeler gauges, or laser sensors to measure the flatness at different points along the coil's length. Automated systems use advanced technologies like laser scanning or optical sensors to quickly and accurately detect any flatness variations in the steel coils. These inspections help ensure that the coils meet the required flatness specifications and quality standards.

- Q: I have a steel plate 3' long x 2 wide x 3/16 thick. I have a 1/2 diameter hole with the center 3/4 from the end. Tensile strength is 38,000psi. A chain goes through the hole and is connected to a load. how does one determine how much tension the chain can have before it rips through the hole?

- Your title asks for the working load, yet your problem asks for the failure load (ripping the plate). These are two different things, since there must be a factor of safety on the failure load to get to the working load. The factor of safety varies from code to code and depending on what the plate/chain is being used for. The failure load would be the net cross section of the plate (after subtracting out the hole) x the strength of the plate. In this case it would be (2 - .5)*3/16*38000psi=10,687.5 lbs You would also need to check the strength of the chain to make sure that it doesn't break before the plate.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications in various industries such as automotive, construction, manufacturing, and energy. They are commonly used for making components and parts in vehicles, buildings, appliances, and machinery. Steel coils can also be employed in the production of pipes, tubes, and electrical appliances. Additionally, they are utilized in the energy sector for manufacturing power transmission equipment and storage tanks.

- Q: How are steel coils used in the production of steel latches?

- Steel coils are used in the production of steel latches as the primary material for manufacturing the latch components. These coils are processed through various stages like cutting, shaping, and forming to create the desired latch design. The steel coils provide the necessary strength and durability required for the latch to function effectively and securely.

- Q: Can steel coils be coated with anti-counterfeit materials?

- Yes, steel coils can be coated with anti-counterfeit materials. These materials can include specialized coatings, holograms, unique serial numbers, or other security features that help prevent counterfeiting and ensure the authenticity of the steel coils.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price in Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords