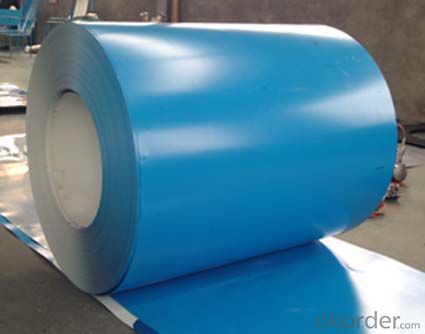

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

5.FAQ

1. What’s the application of this product?

surface sheet of balcony, frame of window, etc.

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after liquid dope with several layers of color

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• Superior workability

• High strength

• Good visual effect • Good capable of decoration

- Q: Brass as a rule I believe is betterhowever I do not plan to get into reloading any time soon I just want some cheap practice ammo so will steel case ammo hurt my gun (semi auto) any more than brass ammo and if so how much more?

- I think you answered the question correctly yourself. Yes. BRASS CASE IS BETTER. MUCH MUCH BETTER. Steel case is for the birds. Brass case feeds better in semi-autos as far as I can remember. High end guns all the way to cheapo's, the brass stuff is better. Ever notice how steel case cartridges almost always seem to have visible bulges in the cases right at the butt ends of the bullets? ? ? Not quite so with brass ammo. Cheap shots or expensive shots I prefer ammo in brass.

- Q: I'm writing a book, and there is a part where there is a death arena with a white-hot river of steel. How hot would that be?

- White-hot steel is ~1200? C (2190 ?F) and above, though the exact temperature depends on the steel alloy used. To give you an idea of how hot this is: 5500? C surface temperature of the sun 1536? C Melting point of iron 1063? C Melting point of gold 660? C Melting point of aluminum 427? C Surface temperature of the sunward face of the planet Mercury 290? C Temperature of a commercial oven broiler

- Q: What are the different methods of corrosion protection for steel coils?

- There are several different methods of corrosion protection for steel coils, each with its own advantages and disadvantages. 1. Coating: One of the most common methods is to apply a protective coating to the steel coils. This can be done through a variety of techniques such as hot-dip galvanizing, electroplating, or painting. Coatings provide a barrier between the steel surface and the corrosive environment, preventing direct contact and thus reducing the risk of corrosion. 2. VCI (Vapor Corrosion Inhibitor): Another method is the use of VCI materials, which release chemicals that inhibit corrosion when in contact with the steel surface. These materials can be applied as coatings, films, or papers, and are particularly useful for long-term storage or shipping of steel coils. 3. Cathodic Protection: This method involves the use of sacrificial anodes or impressed currents to protect the steel coils. Sacrificial anodes, typically made of zinc or aluminum, are connected to the steel surface. These anodes corrode instead of the steel, sacrificing themselves to protect the coils. Impressed current systems use a direct electrical current to prevent corrosion on the steel surface. 4. Wrapping and Packaging: Proper wrapping and packaging of steel coils can also provide corrosion protection. This includes using moisture barrier films, desiccants, or absorbent materials to reduce the moisture content around the coils. Additionally, ensuring adequate ventilation and avoiding contact with other corrosive substances can help prevent corrosion. 5. Environmental Control: Controlling the environment in which the steel coils are stored or used is crucial for corrosion protection. This may involve maintaining proper humidity levels, controlling temperature, and managing air quality. By minimizing exposure to corrosive elements such as moisture, salts, or chemicals, the risk of corrosion can be significantly reduced. It is important to note that the choice of corrosion protection method depends on various factors such as the specific application, budget constraints, and desired lifespan of the steel coils. A combination of these methods may also be used to provide enhanced protection against corrosion.

- Q: Are steel or graphite clubs better?

- I use steel shaft golf clubs (mens so called clubs) I find the garphite shaft that is typically used for womens clubs is too light and I have a messy swing Callaway Big Bertha is GREAT .... very forgiving club and the oversized clubhead is great for beginners up to advanced. *****FOR MEN - STEEL******* no graphite (just the woods have graphite shafts but the irons are steel

- Q: could someone please explain to me in detail the functions of stainless steel wall ties?

- wall ties are used to tie brick coursing to the back up wall...stainless steel will simply last longer than the others but you will pay dearly for them...

- Q: How are steel coils inspected for quality assurance?

- Steel coils are inspected for quality assurance through a combination of visual inspections, measurements, and non-destructive testing techniques. These inspections typically involve checking for surface defects, such as cracks, scratches, or corrosion, as well as ensuring the dimensions and weight of the coils meet the required specifications. Non-destructive testing methods, such as ultrasonic or magnetic particle testing, are also used to detect any internal defects that may not be visible to the naked eye. Overall, these comprehensive inspections help ensure that steel coils meet the desired quality standards.

- Q: Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- This Site Might Help You. RE: Steel vs. Dark Pokemon? Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- Q: How are steel coils used in the production of automotive structures?

- Various methods involve the usage of steel coils in the production of automotive structures. To begin with, these coils serve as the primary material for manufacturing car bodies and frames. Typically composed of high-strength steel, known for its durability and crashworthiness, these coils undergo processing and forming to create different automotive components such as panels, doors, roofs, and pillars. Moreover, steel coils are also utilized in the creation of various structural components within an automobile. For instance, they contribute to the fabrication of suspension systems, chassis, and other vital parts that provide stability, strength, and support to the vehicle. Steel coils frequently find application in the production of structural beams, reinforcement bars, and other load-bearing elements that ensure the overall strength and safety of the vehicle. Furthermore, steel coils play a significant role in the manufacturing of automotive parts that require precise shaping and forming processes. These coils are fed into stamping presses, where they undergo a series of operations including cutting, bending, and shaping to produce intricate parts such as brackets. The versatility of steel enables the production of complex automotive structures with exceptional accuracy and precision. Additionally, steel coils are crucial in the production of automotive exhaust systems. Typically composed of stainless steel, which exhibits excellent resistance to corrosion and high temperatures, these coils are formed and welded into exhaust pipes, mufflers, and catalytic converters, guaranteeing the durability and longevity of these critical components. In conclusion, the utilization of steel coils is essential in the production of automotive structures. They are employed in the creation of car bodies, frames, suspension systems, chassis, and other structural components. Steel coils also play a vital role in the manufacturing of precise and intricate automotive parts, as well as exhaust systems. Overall, the presence of steel coils contributes significantly to the strength, safety, and longevity of automotive structures.

- Q: What are the main properties of steel coils?

- Steel coils have several main properties that make them highly desirable for a wide range of applications. Firstly, steel coils are known for their exceptional strength and durability. They have a high tensile strength, meaning they can withstand heavy loads and resist deformation. This makes steel coils ideal for applications that require structural integrity and reliability. Secondly, steel coils are highly resistant to corrosion. They have a natural ability to form a protective oxide layer on their surface, which prevents rust and other forms of corrosion. This property makes steel coils suitable for outdoor applications or environments with high humidity or exposure to chemicals. Additionally, steel coils have excellent thermal conductivity, allowing them to efficiently transfer heat. This property makes them commonly used in heating and cooling systems, as well as in the production of various appliances and machinery. Furthermore, steel coils have good formability, meaning they can be easily shaped or bent into different forms without losing their strength. This property makes them versatile and adaptable for various manufacturing processes, such as stamping, rolling, or welding. Lastly, steel coils are available in a wide range of grades and thicknesses, allowing for customization based on specific application requirements. This versatility makes steel coils suitable for a diverse range of industries, including automotive, construction, manufacturing, and energy. Overall, the main properties of steel coils include strength, durability, corrosion resistance, thermal conductivity, formability, and versatility. These properties make steel coils a popular and reliable choice for a multitude of applications.

- Q: How are steel coils used in the manufacturing of appliances?

- Steel coils are used in the manufacturing of appliances as they are transformed into various components such as frames, panels, and inner structures. These coils are processed and shaped through cutting, bending, and stamping techniques to create the necessary parts, ensuring durability and strength in the final product.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords