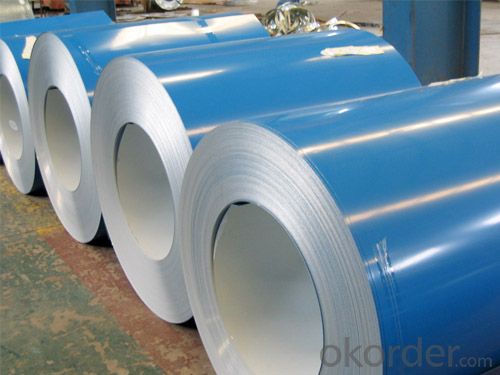

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with P r ime Quality and Lowest Price Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

8Zinc coating: 60-275G/M2, both sides

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Surface finish: with or without protect film

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Thickness : 0.14-1.20 mm

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- i have steel and i like the way it sounds but i like nylon better

- Q: How are steel coils inspected for coil weight accuracy?

- Steel coils are inspected for coil weight accuracy through the use of weighing scales or load cells. These devices are placed beneath the coil during the inspection process to accurately measure its weight.

- Q: How are steel coils used in the manufacturing of exhaust systems?

- Steel coils are used in the manufacturing of exhaust systems as they provide the necessary raw material for forming various components such as pipes, mufflers, and brackets. The coils are typically processed through cutting, bending, welding, and shaping techniques to create the specific parts required for the exhaust system.

- Q: Can steel coils be coated with chrome?

- Yes, steel coils can be coated with chrome. The process of chrome plating involves the application of a thin layer of chromium onto the surface of the steel coils to enhance their appearance, provide corrosion resistance, and improve their durability.

- Q: Can steel coils be perforated?

- Yes, steel coils can be perforated.

- Q: What are the different surface treatments available for steel coils?

- There are various surface treatments available for steel coils, including hot-dip galvanizing, electro-galvanizing, zinc plating, painting, powder coating, and organic coating.

- Q: Can steel coils be cut?

- Yes, steel coils can be cut using various methods such as shearing, sawing, or laser cutting, depending on the thickness and type of steel.

- Q: What are the different types of steel coil packaging systems?

- There are several different types of steel coil packaging systems available, including horizontal coil packaging systems, vertical coil packaging systems, and automatic coil packaging systems. Each type offers unique features and benefits depending on the specific requirements of the steel coil packaging process.

- Q: What are the common surface treatments for galvanized steel coils?

- Galvanized steel coils can undergo various surface treatments to improve their corrosion resistance and appearance. Passivation is one such treatment, where a protective material like zinc phosphate or chromate is applied to create a barrier against moisture and atmospheric elements. This also enhances the adhesion of subsequent coatings or paints. Another treatment is chromate coating, which involves applying a thin layer of chromate to the steel surface. This provides extra protection against corrosion and enhances the steel's appearance. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is a common treatment that involves applying a thin layer of oil to prevent rust and corrosion during storage and transportation. It also offers temporary protection against moisture and other environmental factors until the steel is further processed or used. These surface treatments are widely used to improve the performance, durability, and appearance of galvanized steel coils, ensuring they can withstand harsh conditions and maintain their quality over time.

- Q: Does steel have a valence number and if so, what is it?

- Steel is a mixture, so it doesn't have any valence number. On the other hand, all of the components of the steel mixture are in their elemental forms, so all the various valences are zero.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with P r ime Quality and Lowest Price Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords