Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Best Price Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted GI Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted GI Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted GI Steel Coil Images

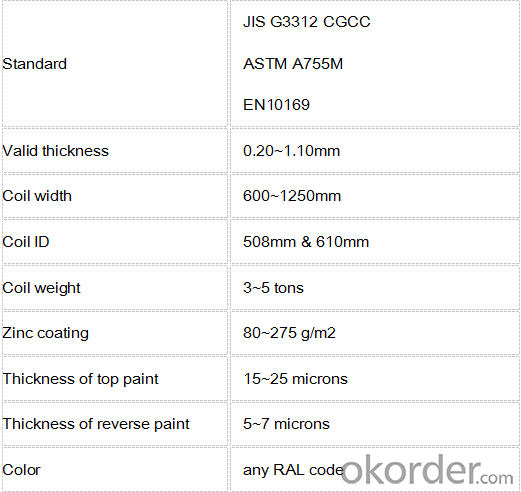

4.Pre-painted GI Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted GI Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: i was giving this old knive. the knife part is stainless steel and has a couple rust spots but im not sure that the handle is (i think stainless) but it has this un smooth surface i dont think its rust because its not brown. would rubbing alcohol help clean it?

- You can also try Barkeepers Friend.

- Q: How are steel coils used in the manufacturing of body panels?

- Steel coils are used in the manufacturing of body panels by being processed and shaped into flat sheets or strips. These sheets or strips are then further formed, cut, and welded to create various body panels, such as doors, hoods, and fenders, which are essential components of vehicles.

- Q: How are steel coils inspected for quality control?

- Steel coils are inspected for quality control through a series of rigorous tests and inspections. This typically involves visual checks for any surface defects, such as scratches or dents, as well as measurements of dimensions, weight, and thickness. Additionally, non-destructive testing techniques like ultrasonic or magnetic particle testing may be conducted to detect internal flaws or inconsistencies in the steel. These comprehensive inspections ensure that only high-quality steel coils are approved for use.

- Q: I heard about a new bike the specialized allez steel. Has anyone heard anything about it. it will have all brand new components like shimano 2300 parts and everything. it looks nice.

- Steel? I doubt it's made out of steel, more labor and a heavier frame. Most likely aluminum. Shimano 2300 you say? The Shimano 2300 is the lowest of the low of Shimano road components. Most likely not too reliable and heavy. www.cyclestore .uk/productDetai... I think this is what you might be looking for.

- Q: I want to buy a machete made of 1055 carbon steel, and want to know if this steel is durable for repeated use, or even combat use.

- 1055 Steel

- Q: How are steel coils used in the production of steel brackets?

- Steel coils are used in the production of steel brackets by being processed and cut into the desired shape and size. The coils serve as the primary raw material, providing the necessary strength and durability for the brackets.

- Q: i have noticed in guns, and artillery the shell casings are always made out of brass. brass is expensive, weaker and dosnt look as good as steel. so why use it for casings? i am aware some of the case must be deformed. but just a small brass percussion cap could be used just for that and steel for the rest. whats going on?

- Brass has a natural lubricity that makes easier to extract after firing. It also can easily be resized for reloading. Steel offers neither of these properties. It cannot be reloaded so is good for only one single use. Brass has simply shown, by virtue of its metallic characteristics, to be the best choice for manufacturing cartridges.

- Q: Are steel coils used in appliances manufacturing?

- Yes, steel coils are commonly used in appliances manufacturing. They are widely used for constructing the frames, cabinets, and other structural components of various appliances such as refrigerators, washing machines, dishwashers, and ovens. Steel coils provide strength, durability, and stability to these appliances, making them an essential component in their manufacturing process.

- Q: What are the different types of steel coil edge treatments?

- In the manufacturing and processing of steel coils, various steel coil edge treatments are employed. These treatments serve to improve edge quality, protect against damage, and facilitate the handling and processing of the coils. Some of the prevalent types of steel coil edge treatments are as follows: 1. Mill Edge: The steel mill provides this standard edge treatment, which is the raw edge of the steel coil generated during the hot rolling process. The mill edge is typically sharp and may exhibit some irregularities. 2. Slit Edge: Slit edge treatment involves slitting the coil to the desired width and subsequently processing the edges to eliminate any burrs or unevenness. Compared to mill edge coils, slit edge coils have smoother edges. 3. Deburred Edge: The deburring process removes any sharp or rough edges from the coil using specialized equipment or techniques, resulting in a smoother and safer edge. Deburred edges find common use in applications where safety and handling are of utmost importance. 4. Rounded Edge: Rounded edge treatment entails rounding the edges of the coil to minimize the risk of damage during handling and processing. This treatment is frequently employed in applications where the coil must be uncoiled or fed into machinery without incurring any damage. 5. Beveled Edge: Beveling involves chamfering or cutting the edges of the coil at an angle. Beveled edges are utilized in applications where easy insertion, joining, or welding of the coil is required. The beveling process also enhances the strength and durability of the edge. 6. Sheared Edge: Shearing is a cutting process that employs high-pressure blades or scissors to cut the coil to the desired width. Sheared edge treatment yields a clean and straight edge, devoid of burrs or irregularities. It is commonly employed in applications that necessitate precise dimensions and a smooth edge. These are merely a few examples of the various steel coil edge treatments commonly employed in the industry. The selection of edge treatment depends on specific application requirements, such as handling, processing, safety, and aesthetics.

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by placing them on wooden or steel pallets, securing them with steel bands or straps, and covering them with protective wrapping such as plastic or waterproof paper. This packaging ensures the coils remain stable, protected from corrosion, and are easy to handle and transport.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Best Price Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords