Pre-Painted Galvanized/Aluzinc Steel Coil DX51D with Good Visual Effect

- Loading Port:

- China main port

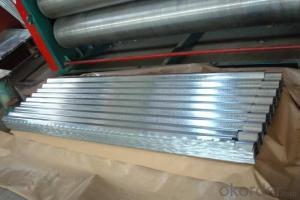

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil DX51D with Good Visual Effect

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-Painted Galvanized/Aluzinc Steel Coil DX51D with Good Visual Effect:

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images:

4.The Specification:

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Width: 20-1250mm

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

surface treatment: color coated

coil weight: 4-7 tons

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil:

1. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can cold rolled galvanized steel coils be acid washed after oxidation?

- If it has been galvanized, it can not be pickled, and if it is pickled, it may corrode the zinc layer

- Q: What are the different surface treatments applied to steel coils?

- Some of the different surface treatments applied to steel coils include galvanizing, which involves coating the steel with a layer of zinc to protect it from corrosion, painting or powder coating to enhance the aesthetics and provide additional protection, and passivation to remove any impurities on the surface and improve its corrosion resistance.

- Q: How do steel coils contribute to the circular economy?

- The recyclability and reusability of steel coils make them valuable contributors to the circular economy. The main goal of the circular economy is to minimize waste and promote the continuous use of resources, and steel coils align perfectly with this concept. To begin with, steel coils are manufactured using recycled steel, which reduces the need for extracting raw materials and the associated negative environmental effects. By utilizing recycled steel, we can conserve natural resources and decrease energy consumption in the manufacturing process. This practice not only lowers carbon emissions but also decreases the overall ecological footprint. Furthermore, steel coils can be easily recycled once they reach the end of their lifespan. Steel has one of the highest recycling rates globally. When the coils are no longer in use, they can be collected, processed, and transformed into new steel products without losing their properties or quality. This closed-loop recycling system ensures that steel resources are continuously utilized, reducing the need for virgin steel production. In addition, steel coils support the circular economy by enabling the production of durable and long-lasting products. Steel is renowned for its strength and durability, making it ideal for various applications such as construction, automotive, and packaging. By using steel coils, we can manufacture products with extended lifespans, minimizing the need for frequent replacements and reducing waste generation. Moreover, steel coils can be reused multiple times before being recycled. They can be rewound, reshaped, or repurposed for different applications, thus extending their lifecycle and reducing the demand for new coils. This aspect of reusability contributes to resource efficiency and waste reduction. To summarize, steel coils play a significant role in the circular economy by being made from recycled steel, easily recyclable themselves, enabling the production of durable products, and promoting reuse. Their contribution helps close the loop in the steel industry, conserves natural resources, reduces waste generation, and minimizes environmental impact.

- Q: Does anyone know how to make a steel helmet, or does anyone know where to direct me websites-wise? i've just started looking on the web for info, so when i get back here i might've already found some info, but more wouldn't hurt, especially if from people who are interested on the subject. i know nothing about metallurgy, nothing on the art of metal working etc... please help.

- The okorder (Artist Blacksmiths) or on the sites of the two organizations that reproduce old costumes and tools - one is called The Society for Creative Anachronism, not sure of the other. Search terms to use might be hammering a helmet and forging medieval armor

- Q: How do steel coils contribute to strength and stability in structures?

- Steel coils are essential components in many structures due to their significant contribution to strength and stability. The inherent properties of steel, combined with the unique design of coils, make them an ideal choice for enhancing the structural integrity of various applications. Firstly, steel itself is renowned for its exceptional strength. It has a high tensile strength, which means it can resist large amounts of tension without breaking or deforming. When steel is formed into coils, it further enhances its strength by distributing the load evenly across the entire structure. This uniform distribution of force helps prevent localized stress concentrations, ensuring that the structure can withstand heavy loads and external pressures more effectively. Additionally, steel coils provide stability to structures by offering rigidity and resistance against deformation. Steel is known for its stiffness, which prevents excessive flexing or bending under loads. The tightly wound coils create a robust and compact structure that can efficiently resist dynamic forces, such as wind, earthquakes, or vibrations. This high resistance to deformation minimizes any potential damage to the structure, thereby maintaining its stability and integrity. Moreover, steel coils also contribute to the longevity and durability of structures. Steel possesses remarkable durability, as it is highly resistant to corrosion, rust, and deterioration over time. This longevity ensures that structures built with steel coils can remain strong and stable for extended periods, requiring minimal maintenance or repairs. Furthermore, steel coils offer versatility in design and construction. The ability to shape steel into various coil sizes and configurations allows for customization based on specific structural requirements. Architects and engineers can utilize steel coils to create complex structures while maintaining their strength and stability. This versatility allows for innovative and efficient design solutions, making steel coils a preferred choice in many construction projects. In conclusion, steel coils play a crucial role in enhancing the strength and stability of structures. The inherent strength of steel, combined with the unique design of coils, provides structures with the necessary rigidity, resistance to deformation, and durability. Additionally, the versatility of steel coils allows for customization and innovative design solutions. Overall, steel coils significantly contribute to the overall integrity and longevity of structures, making them an essential component in the construction industry.

- Q: How are steel coils used in the manufacturing of automotive frames?

- Steel coils are used in the manufacturing of automotive frames by being shaped and formed into the desired dimensions and then welded together to create a strong and durable structure that provides stability and support to the vehicle.

- Q: I heard that the stores don't sale Steel Legion anymore...Is this true..Also I want to know why they cost more than regular Imperial Guardsmen..Such as Cadian...Do they have something Special?Also what do I need to buy to have a complete Steel Legion army..I need two squads of troops of 20's?and two sergeants for each squad.and one commiser?Well I;m guessing..someone please help...I havent played in about 4 years.

- The stock at various shops may vary, but you can buy Steel Legion miniatures through the mail order, or the Internet from GW. Cadian troopers are plastic, There are no plastic Steel Legion troops. The plastic models are (a tiny bit) not so horribly expensive as the metallic ones. The minimum requirements for your force vary from mission to mission, but a good start is 1 HQ unit 2 Troop choices. Also, the total points cost of the battle is to be considered. (Usually 500, 1000, or 1500 points.) What you described is one possible choice, although the size of IG squads is 10 and not 20. And you must include a command squad, the commissar is optional. You might change the other 20 troops for a tank, or a squad of Sentinels. Happy gaming!

- Q: Not sure if stainless steel is actually sealable but what's the best way to clean a brushed stainless steel appliance to not get so many finger prints...etc. I have stainless steel wipes that I used on another appliance and they don't work so great.

- Straight white vinegar on a clean white cloth does an amazing job on all my appliances. Makes the kitchen smell great to.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc or another protective coating is applied to the surface of the steel. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel and minimizing the risk of corrosion. Additionally, steel coils are often stored in dry, enclosed spaces or wrapped with moisture-resistant materials such as plastic or wax paper to further protect them from humidity.

- Q: What is the standard diameter of steel coils?

- The standard diameter of steel coils can vary depending on the specific industry and application. However, in general, the standard diameter of steel coils typically ranges from 24 inches to 72 inches. This range allows for easy handling, transportation, and storage of the coils. It is important to note that different industries may have their own specific requirements for steel coil diameters based on factors such as equipment compatibility, production processes, and logistical considerations.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil DX51D with Good Visual Effect

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords