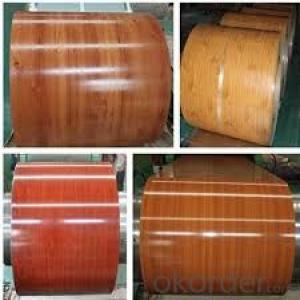

PPGI Prepainted galvanized Steel Coil (PPGI/PPGL) /Roofing steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,GB,JIS | Grade: | CGCC, DX51D | Thickness: | 0.25-0.8MM |

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | CNBM | Type: | Steel Coil |

| Technique: | Cold Rolled | Surface Treatment: | Coated | Application: | Roofing |

| Special Use: | Silicon Steel | Width: | 800-1250MM | Color: | Ral or according to sample |

Packaging & Delivery

| Packaging Detail: | color steel coil STANDARD EXPORT SEAWORTHY PACKING |

| Delivery Detail: | 25 DAYS AFTER DOWN PAYMENT |

Specifications

color steel coil

Prime Quality, Quick Delivery, Competitive Price

Prepainted Galvanized Steel Coil (PPGI/PPGL)

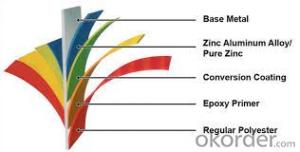

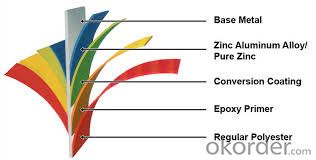

Base material: Hot dipped galvanized steel

Width: available from 800MM to 1250MM

Width Tolerance: within 0.02MM

Thickness: available from 0.18MM to 0.80MM

Thickness Tolerance: within 0.15MM

Performance: Smooth or Matte

Color: according to RAL standard

Lacquer Coating thickness: according to customer needs

Supply capacity: 8,000 Metric Ton per month

Our products has good performance on combining force and anti-erosion. We offer fine quality products and best price for our international customers.

COLOR COATING LINE

A Dual Uncoiler

B Stitcher

C Bridles

D Entry Accumulater

E Degreasing & Chemical Section

F Prime Coater

G Prime Oven

H Prime Water Quench

I Finish Coating

J Finish Back Coater

K Finish Oven

L Finish Water Quench

M Exit Accumulater

N Recoiler

- Q: How do steel coils contribute to the renewable energy equipment industry?

- Steel coils contribute to the renewable energy equipment industry by playing a crucial role in the manufacturing of various renewable energy components. They are used to create structural frames, support structures, and brackets for wind turbines, solar panels, and other renewable energy systems. Additionally, steel coils are essential in the production of electrical transformers and transmission lines, which are integral to the distribution of renewable energy. Overall, steel coils provide the strength, stability, and durability required for the efficient and long-lasting operation of renewable energy equipment.

- Q: Is steel harder than iron or is iron harder than steel?Please explain... and help!Thanks

- steel is harder than iron Iron is a chemical element. It is a strong, hard, heavy gray metal. It is found in meteorites. Iron is also found combined in many mineral compounds in the earth's crust. Iron rusts easily and can be magnetized and is strongly attracted to magnets. It is used to make many things such as gates and railings. Iron is also used to make steel, an even harder and tougher metal compound. Steel is formed by treating molten (melted) iron with intense heat and mixing it (alloying) with carbon. Steel is used to make machines, cars, tools, knives, and many other things.

- Q: I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- Soldering to steel is difficult. An electric iron may be enough depends on power. The steel must be clean. An abrasive like fine steel wool,fine sandpaper or even a rubber pencil eraser will work. Next an acid flux for the solder. Most electronic solder flux is not active enough for steel. Plumbers solder usually is. Plumbers solder is Lead free and has a slightly higher melting temp.

- Q: How are steel coils used in the production of building facades?

- Steel coils are commonly used in the production of building facades as they provide strength, durability, and versatility. These coils are typically processed into flat sheets or panels and then cut, shaped, and attached to the framework of the facade. The steel coils can be coated with various finishes or paints to enhance their aesthetic appeal and protect against corrosion. Overall, steel coils play a crucial role in constructing robust and visually appealing building facades.

- Q: Steel is a mixture of Iron Carbon . So , is steel a metal or non - metal ?

- Boeing is building the new 787 dreamliner almost completely out of composites. If you take a look at an Ashby chart (Strength vs. Density) you would see that there are composites that are as strong as steel but as dense as aluminum.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

- Q: How are steel coils used in the production of shipbuilding components?

- Steel coils are used in the production of shipbuilding components as they are the primary raw material for manufacturing various structural and mechanical parts, such as hulls, decks, bulkheads, and frames. These coils are unwound, cut, shaped, and welded to form the required sections and profiles, providing the necessary strength and durability to withstand the harsh marine environment.

- Q: I need steel toe shoes for a workplace, where can I get them?I live in Surrey,UK.

- by on the internet or ppe clothing shops

- Q: What are the disadvantages of using steel coils?

- One disadvantage of using steel coils is their high weight and bulkiness, which can make transportation and handling more difficult and costly. Additionally, steel coils are prone to rust and corrosion, requiring proper maintenance and protective coatings to prevent deterioration. Lastly, steel coils can be expensive to produce and purchase, making them less cost-effective compared to alternative materials in certain applications.

- Q: What are the common uses of galvanized steel coils?

- Galvanized steel coils are commonly used in various industries such as construction, automotive, and manufacturing. They are primarily used for making metal roofs, walls, and fences due to their corrosion-resistant properties. Additionally, galvanized steel coils are utilized in the production of air conditioning ducts, electrical appliances, and agricultural equipment.

Send your message to us

PPGI Prepainted galvanized Steel Coil (PPGI/PPGL) /Roofing steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords