PPGI_PPGL_GI_GL _CR_ HR Steel Coil with Lower Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

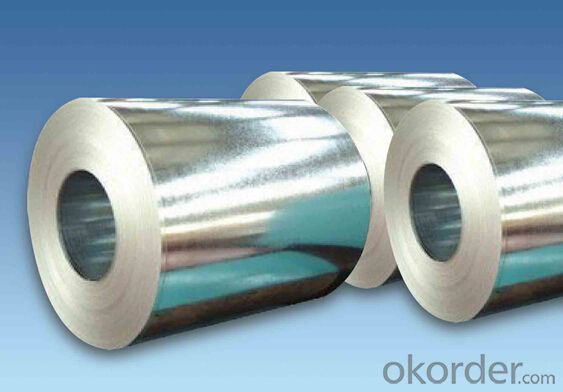

Hot Sales PPGI PPGL GI GL CR HR Steel Coil with Lower Price

Quick Details

Name | Hot Rolled Steel Coil |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

1.PPGL Specification | Thickness :0.2-5.0mm width:600-1500mm |

2.Brand: | Zinc galv, HBIS-Tangsteel, shousteel, Ansteel etc. |

3.production | coated |

4.standard | ASTM Gr.B JIS DIN |

5.steel grade | DX51D+AZ/GX51D+Z, SGCC |

6.Unite length | Coil or 5-12m as customer’s requirements per plate |

7.quality | top |

8:place of origin | china |

9. Outside coating: | Coated, galvanized, galvalume or as per required by customer's |

10. Third party inspection | SGS/BV |

Company Information

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. |

l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours | |

Advantages | Industry experience over 20 years. |

Shipment of goods -More than 70 countries worldwide. | |

The most convenient transport and prompt delivery. | |

Competitive price with best service. | |

High technical production line with top quality products. | |

High reputation based on best quality products. |

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the advantages of using special steel in manufacturing?

- There are several advantages of using special steel in manufacturing. Firstly, special steel has superior strength and durability compared to regular steel, making it ideal for applications that require high levels of toughness and resistance to wear and tear. Additionally, special steel offers better corrosion resistance properties, allowing the manufactured products to withstand exposure to harsh environments or corrosive substances. Moreover, special steel can be tailored to have specific mechanical properties, such as increased hardness or flexibility, allowing manufacturers to create products with precise specifications. Lastly, special steel often exhibits excellent heat resistance, making it suitable for applications that involve high temperatures or extreme thermal conditions. Overall, the use of special steel in manufacturing provides enhanced performance, longevity, and reliability to the end products.

- Q: What are the different types of wear-resistant steel?

- There are several different types of wear-resistant steel, including AR400, AR500, Hardox, and Domex. These steels are specifically designed to withstand abrasion and provide excellent durability in applications where materials are subjected to constant wear and impact.

- Q: What are the applications of special steel in the marine sector?

- Special steel is extensively used in the marine sector due to its unique properties. It is used in various applications such as shipbuilding, offshore platforms, and marine equipment manufacturing. Special steel provides excellent corrosion resistance, high strength, and durability, making it ideal for marine environments that are highly corrosive and subject to extreme conditions. It is used for constructing hulls, propeller shafts, pipelines, and various components of ships and offshore structures. Additionally, special steel's ability to withstand impact and fatigue makes it suitable for marine applications where safety and reliability are crucial.

- Q: What are the main advantages of using special steel in the oil and gas industry?

- The main advantages of using special steel in the oil and gas industry include its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressures. Special steel is specifically designed and manufactured to meet the demanding requirements of the industry, ensuring reliable performance and longevity. It also offers excellent weldability, which is crucial for constructing pipelines and equipment used in oil and gas operations. Additionally, special steel's durability and resistance to fatigue make it ideal for withstanding the harsh conditions and environments encountered in the oil and gas sector.

- Q: How does special steel perform in additive manufacturing applications?

- Special steel performs well in additive manufacturing applications due to its high strength, durability, and resistance to wear and corrosion. The unique properties of special steel, such as its ability to withstand high temperatures and extreme environments, make it an ideal material for 3D printing processes. Additionally, the flexibility and customization offered by additive manufacturing allows for the creation of complex geometries and intricate designs, further enhancing the performance of special steel in various applications.

- Q: How is boron steel used in automotive safety applications?

- Boron steel is used in automotive safety applications due to its high strength and ability to absorb and distribute impact energy. It is commonly used in the construction of safety cages, reinforcements, and components such as side impact beams, door beams, and crash boxes. Its exceptional crashworthiness properties help improve the structural integrity of vehicles, enhance occupant protection, and reduce the risk of serious injuries during accidents.

- Q: What are the main industries that use special steel?

- Special steel is extensively utilized in various industries due to its exceptional properties and characteristics. The following sectors heavily depend on special steel: 1. Automotive Industry: Numerous automotive components, including engine parts, transmission gears, suspension systems, and exhaust systems, rely heavily on special steel. Its outstanding strength, durability, and resistance to wear and corrosion make it an ideal choice for these applications. 2. Aerospace Industry: The aerospace industry highly values special steel as it is essential in the production of aircraft components such as turbine blades, landing gears, and structural parts. The unique properties of special steel, including high temperature resistance, strength, and lightweight nature, play a crucial role in ensuring the safety and efficiency of aerospace systems. 3. Energy and Power Generation: Special steel finds extensive applications in the energy sector, particularly in power plants and nuclear facilities. Turbines, generators, and heat exchangers are constructed using special steel, where its exceptional strength and high temperature resistance are vital for efficient energy production. 4. Oil and Gas Industry: In the oil and gas sector, special steel is widely employed in drilling equipment, pipelines, valves, and other components. The ability of special steel to resist corrosion, withstand extreme conditions, and provide high strength makes it the preferred choice in this industry. 5. Construction and Infrastructure: Special steel is crucial in the construction industry for various purposes, including building structures, bridges, and high-rise buildings. Its high tensile strength, durability, and resistance to impact and corrosion ensure the integrity and longevity of these structures. 6. Tool and Die Making: Special steel is extensively used in the manufacturing of tools and dies for various industrial processes. Its hardness, toughness, and wear resistance make it an ideal material for applications such as cutting, drilling, and shaping metals. 7. Defense and Military: The defense and military sector heavily relies on special steel for the production of armored vehicles, weapons, and other military equipment. Special steel's ability to withstand high impacts, resist ballistic penetration, and maintain structural integrity under extreme conditions is crucial for ensuring the safety and effectiveness of military operations. In conclusion, the automotive, aerospace, energy and power generation, oil and gas, construction and infrastructure, tool and die making, and defense and military industries heavily depend on special steel. These industries benefit greatly from the unique properties of special steel, including high strength, durability, resistance to wear and corrosion, and the ability to withstand extreme conditions.

- Q: How does special steel contribute to the electrical conductivity of products?

- Special steel can contribute to the electrical conductivity of products in several ways. Firstly, special steel alloys can be formulated with specific chemical compositions that enhance their electrical conductivity. For example, adding elements such as copper, silver, or nickel to the steel can increase its electrical conductivity by providing more pathways for the flow of electric current. Additionally, the microstructure of special steel can be manipulated to improve electrical conductivity. By controlling the grain size and orientation of the steel, it is possible to reduce the resistance to the flow of electrons, thereby increasing the overall conductivity of the material. Furthermore, special steel can be heat treated or subjected to other processes to enhance its electrical conductivity. Heat treatment techniques like annealing or tempering can help to remove impurities and improve the crystal structure of the steel, resulting in improved electrical conductivity. Moreover, special steel can also be designed to have low magnetic permeability, which means it exhibits less resistance to the flow of magnetic fields. This property is beneficial for applications where electromagnetic interference needs to be minimized, such as in electrical connectors or transformers. In summary, special steel contributes to the electrical conductivity of products through various means, including chemical composition, microstructural control, heat treatment, and low magnetic permeability. By optimizing these factors, special steel can significantly enhance the performance of electrical components and systems.

- Q: What are the applications of special steel in the medical field?

- Special steel has various applications in the medical field due to its unique properties and characteristics. One of the primary applications of special steel in the medical field is in the manufacturing of surgical instruments. Special steel, such as stainless steel, is widely used to produce sharp, durable, and corrosion-resistant surgical instruments like scalpels, forceps, scissors, and surgical needles. These instruments need to be strong enough to withstand repeated use and sterilization without losing their sharpness or integrity, and special steel provides the necessary strength and durability. Another important application of special steel in the medical field is in the production of implants and prosthetics. Special steel alloys, including titanium alloys, cobalt-chromium alloys, and nickel-titanium alloys, are commonly used to manufacture orthopedic implants, dental implants, and various other medical devices. These alloys offer excellent biocompatibility, corrosion resistance, and mechanical strength, making them ideal for long-term implantation in the human body. Additionally, special steel is used in the construction of medical equipment and machinery. Diagnostic machines like MRI scanners and X-ray machines often utilize special steel components due to their magnetic properties and ability to withstand high temperatures. The use of special steel in medical equipment ensures the accuracy, reliability, and safety of these devices. Furthermore, special steel is employed in the manufacturing of medical storage and transportation systems. Steel cabinets, trolleys, and containers are commonly used to store and transport medical supplies, instruments, and samples. Special steel ensures the durability and hygiene of these storage systems, as it is easy to clean, resistant to contamination, and has a long lifespan. In conclusion, the applications of special steel in the medical field are extensive and diverse. From surgical instruments to implants, medical equipment to storage systems, special steel plays a vital role in ensuring the effectiveness, reliability, and safety of medical procedures and treatments. Its unique properties make it an indispensable material in the healthcare industry.

- Q: Can special steel be coated or plated?

- Yes, special steel can be coated or plated with various materials to enhance its properties, protect against corrosion, or improve its aesthetic appearance.

Send your message to us

PPGI_PPGL_GI_GL _CR_ HR Steel Coil with Lower Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords