PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

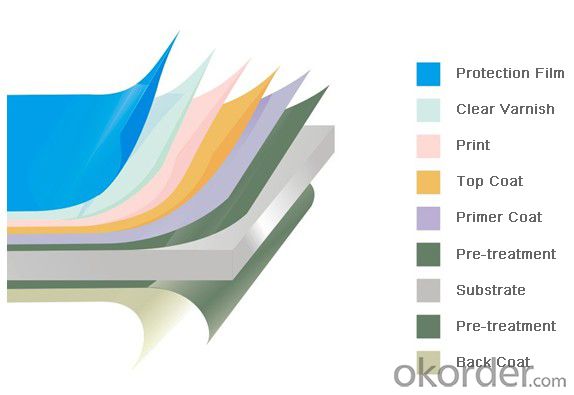

Structure of PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

Description of PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances, |

FAQ of PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. How Do You Do Regarding Quality Control?

Quality is priorty. Duichengmetal people always attach great importance to quality controlling from the very beginning to the very end. We can get BV, SGS certificate also.

- Q: How do steel coils compare to other materials, such as aluminum or copper?

- Steel coils have several advantages over other materials such as aluminum or copper. Firstly, steel is generally stronger and more durable, making steel coils less prone to damage or deformation. Additionally, steel has better heat resistance and can withstand higher temperatures, making it suitable for a wider range of applications. Steel coils also tend to be more cost-effective compared to aluminum or copper, making them a popular choice in various industries.

- Q: What are the different types of steel coil coatings available?

- There are several different types of steel coil coatings available, including polyester, polyurethane, siliconized polyester, fluorocarbon, and plastisol coatings. Each type of coating offers specific properties and benefits, such as durability, corrosion resistance, weatherability, and aesthetics, making them suitable for various applications in industries such as construction, automotive, and appliances.

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as they serve as the core component of the motor's electromagnetic system. These coils are wrapped around an iron core, creating an electromagnetic field when electricity flows through them. This electromagnetic field generates the necessary force that allows the motor to convert electrical energy into mechanical energy, enabling the motor to function and perform various tasks.

- Q: I've created something but it's a huge secret. Anyways I need to know everything and anything about steel. Like the iron steel. ANYTHING AND EVERYTHING. Best answer goes to the person with the most correct information. Please this is really important.

- If you want to know everything about steel, there's no way you're going to get an answer on Yahoo that is comprehensive enough. What you want to do is get some books on steel metallurgy, engineering properties of materials, and maybe machine design depending on your application. Topics will include molecular structure, material properties, alloying, stress and strain, work hardening, creep, computing damage and lifetime cycles, corrosion, toughness vs hardness, heat treating, and a ton of others. If you want to sharpen steel, that is a whole topic in itself concerning different blade profiles and their sharpness, edge holding, ease of sharpening, type of grind etc.

- Q: The hard industrial steels. If there's a bunch, what's a rough average? Also, what is is measured in?

- There is no average, it depends on the type of steel (hundreds) and the (heat/surface) treatment (infinite possibilities). The Rockwell hardness range covers a large scale so for any given range there is a suffix (C is used for most steel) to denote the selected range. The number is a dimensionless constant that correlates to the strength of the material. Materials can also be surface (case) hardened and then the bulk material will be soft and the surface will be hard, this is typical for items like gears and cams that have rolling wear but are not very heavily stressed to require bulk hardness. Most steel that is hardened is first machined to size and then hardened. If more accuracy is required, they are machined to just over net size, hardened and then ground to the final size as the heat treatment can change the size and shape a little as stresses are released. Some examples: Very hard steel (e.g. a higher quality knife blade): HRC 55–66 Axes, chisels, etc.: HRC 40–45 4140 Cr Mb Steel HRC 28 - 36 , bulk hardened to HRC 54, Nitride case hardened to HRC 60 P20 tool steel can be bulk hardened to over HRC 55 and then tempered down from HRC 51 to 28

- Q: I want to experiment with making steel and want to especially make it stronger. And also I want to know if its possible to turn a meteorite into steel?

- If you really want to do this, you should be getting some books on steel metallurgy rather than asking on Yahoo. ASM sells a Metallurgy for the non-metallurgist that would be a good introduction. Most university libraries will have the full ASM handbook that includes detailed information for different grades of steel (vol 1), heat treatment and surface hardening (vol 4), testing (vols 8-12), and casting (vol 15). A reference for continuous cooling transformation diagrams will also help in designing a heat treatment process. If you want to make something stronger than most commercial steels, you'll need to get into nanotechnology and unconventional steel processing methods like powder metallurgy. You can increase the strength of steel by about 1000% by reducing the grain size from 50 micron (typical for conventional processing methods) to 100 nm (achievable through high-energy ball milling). Though you'd also need to customize the chemistry to stabilize the grain size during the necessary thermal processing, I believe zirconium works well with iron.

- Q: I have a set of Ben Hogan Apex Plus Forged Irons, how can i figure out if the shafts are steel or graphite?

- Steel will look like polished steel. And Graphite or CF will be painted or clear over the black CF fibers. Basically - if it looks like steel it is. You could look up you clubs on google also. Many times the shafts have the material, stiffness and other info printed right on them.

- Q: How are steel coils labeled and identified?

- To ensure accurate tracking and handling of steel coils throughout their journey, various methods are employed to label and identify them. The labeling and identification process typically consists of the following steps: 1. Initial Marking: At the outset, the manufacturer's name or logo is affixed to the steel coil, enabling easy identification of the producing company. 2. Unique Identification Number: A distinct identification number, commonly known as a coil number, is assigned to each steel coil. This number is often engraved or imprinted on the surface of the coil and serves the purpose of tracking and managing inventory. 3. Specifications of Size and Weight: Labels indicating the size and weight specifications of the steel coils are attached. This information aids in determining the coil's dimensions and weight capacity, ensuring appropriate handling and transportation arrangements. 4. Indication of Grade and Material: The labeling typically includes information about the grade and material composition of the steel coil. This essential data offers insights into the properties and quality of the steel, guaranteeing its correct utilization in manufacturing processes. 5. Heat or Lot Number: Steel coils may also bear a heat or lot number, which denotes the production batch from which the coil originated. This information contributes to traceability and quality control, simplifying identification in the event of any issues or defects. 6. Barcodes or QR Codes: Many steel coils now feature barcodes or QR codes that can be scanned using automated systems. These codes contain all pertinent information about the coil, streamlining data capture and management throughout the supply chain. Proper labeling and identification of steel coils are of utmost importance for efficient logistics management, inventory control, and quality assurance. By implementing these identification methods, manufacturers, distributors, and end-users can effortlessly track, handle, and utilize steel coils in a secure and productive manner.

- Q: mass of steel ball=66.80 gramsdiameter of steel ball=2.51 cm

- To calculate the density of any object you will always use the formula: Density = Mass / Volume (P=M/V). You have recorded the known values of the mass and the diameter of the ball (sphere), so we have everything needed to calculate the Density. Mass is 66.80g, but we shall need to use another formula to calculate the volume of the sphere. The formula to use is 4/3 X Pi X radius cubed. However, first of all we need to turn your measurement of the diameter of the steel sphere into the radius of the steel sphere (So that it can be substituted in place of the “radius” in the above formula). Simply half the diameter to find the radius. So 2.51 cm divided by 2 is 1.255 cm. Now insert the radius 1.255cm into the above formula. It would be read like this: 4/3 X 3.14159… X 1.255 ?cubed (OR 4/3 X 3.14159 X 1.255X1.255X1.255), = 8.2798. So, now we know that the sphere has a volume of 8.2798 cm cubed, we can use this number in place of the “V” in the density formula P=M/V, and we can also substitute in the Mass (66.80g). So now P=66.80 / 8.2798, which = 8.07g/cm cubed. Now we know that from your measurements, steel has a density of 8.07g/cm cubed! This is fairly close to the real life average density, which if I remember correctly is around 7.8 g/cm cubed. Just remember, though, that as steel is an alloy it’s density is not standard and varies due to carbon content etc. Anyway, I hope that helped you!

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- Damascus steel is the poorest quality. The laminations separate under stress. Centuries ago the only way to get steel bars was to make it up by hammering wires together in a series of welds. The welds usually were porous and the steel would fail. The pattern of the welds is attractive to some people. An old file has good hard steel and wiill make up into a knife if it is annealed to make it easier to shape and cut. The hardness can be restored by tempering. Treating with oil is the cure to prevent rust.

Send your message to us

PPGI Prepainted rolled Steel Coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords