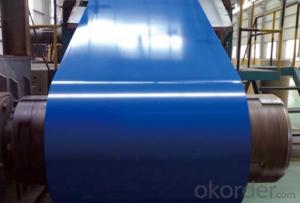

PPGI Prepainted Galvanized Steel Coil With Different Width 1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

0.3mm Thickness PPGI Prepainted Galvanized Steel Coil With Different Width

Product Description

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 25 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

Company Introduction:

CNBM Steel is mainly engaged in producing and exporting galvanized steel coil/sheet(GI), prepainted galvanized steel coil/sheet(PPGI), corrugated galvanized sheet and tinplate coil/sheet. CNBM Steel has also become the agent of hot rolled coil/sheet, cold rolled coil/sheet, I beam, angle steel and channel steel.

Company Culture:

Take customers as the honoured, Take quality as the foundation!

Strive For Survival On The Basis Of Quality!

Why Us:

1. ISO, BV, CE, SGS approved

2. Competitive price and quality from our own factory

3. Efficient service team online for 24 hours

4. Smooth production ability(50000tons/month)

5. Quick delivery and standard exporting package

6. Flexible payment with T/T, L/C, etc

Name | 0.3mm Thickness PPGI Prepainted Galvanized Steel Coil |

Resin constructure | Double painting and double baking process |

Productivity | 150,000Tons/year |

Thickness | 0.12-1.3mm |

Width | 600-1250mm |

Coil Weight | 3-8 Tons |

Inside Diameter | 508mm Or 610mm |

Outside Diameter | 1000mm-1500mm |

Zinc Coating | Z50-Z275G/psm |

Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

Standard | JIS G3322 CGLCC ASTM A755 CS-B |

SurfSurface coating | PE, SMP, HDP, PVDF |

Back side coatingcolor | Light grey, white and so on |

Application | PPGI is featured with light-weight, good looking and |

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

2. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: Are steel coils resistant to rust and corrosion?

- Yes, steel coils are resistant to rust and corrosion. Steel coils are typically made from carbon steel or stainless steel, both of which have excellent corrosion resistance properties. Carbon steel coils are often coated with a protective layer, such as zinc or a polymer coating, to enhance their resistance to rust and corrosion. Stainless steel coils, on the other hand, are inherently corrosion-resistant due to the presence of chromium, which forms a protective oxide layer on the surface of the steel, preventing rust and corrosion. However, it is important to note that the level of resistance to rust and corrosion may also depend on the specific grade and quality of the steel used in the coils, as well as the environmental conditions they are exposed to.

- Q: What are the common coil surface finish standards?

- The common coil surface finish standards include mill finish, brushed finish, mirror finish, and embossed finish.

- Q: I would like to know if steel is basically a very dense crystal, or if it is a different atomic structure

- Steel is made of billions, trillions of very small crystals. This is true of most metals. In order to see the crystal structure of steel, you usually need to cut a sample of it, grind and polish the cut face smooth, then etch the steel with a mixture of nitric acid and alcohol. Without polishing and etching the crystals aren't visible- it just looks like smooth solid metal. Also, in most cases the crystals are small enough that you need a microscope to see them clearly after etching.

- Q: it has 2 be 20 inches overall, and 2and1/2 inches wide and .25 or more inches thick... im thinking truck steel but im not sure thx

- What is the purpose of the knife? What properties do you want? Strength, flexibility, ability to hold an edge, ability to make razor sharp, ease to sharpen, resistance to corrosion, cost? What method are you going to use to make the blade? Cast, forge and hammer, multiple folds? Are you going to be a stabbing knife, a slicing knife, chopping knife, or just a pretty show knife? What is truck steel? Doesn't sound like it would be very good blade steel.

- Q: Is steel cut really better? The nutritional profiles are nealy identical. Which one has the best flavor??Thanks!

- The biggest difference, is steel cut oats tend to be a European way, and Rolled oats are more North American, Irish and Scottish Oats tend to be steel cut, take longer to cook as the germ and whole grain is almost shredded, where with rolled oats it is process to were only a portion of the bran remains, that is why you can by Oat Bran in North America. We have instant, quick and large flake from Quaker, all cook in a matter of between 2-10 minutes, steel cut can take up to 25-30 minutes and do better in a double boiler, my mother tells a story were her grandmother would prepare it at night and let it sit on the back of the wood stove all night for breakfast the next day.

- Q: How are steel coils used in the production of automotive parts?

- Steel coils are used in the production of automotive parts as they are processed and shaped into various components such as body panels, chassis, and structural parts. These coils are typically unrolled, cut, and formed into the desired shape using specialized machinery. The flexibility, strength, and durability of steel make it an ideal material for manufacturing automotive parts, ensuring safety and reliability in the finished products.

- Q: Where can a find a steel scrubber. Its great to clean cooking vessels. Would be great if someone gives me an idea. I did not find it at CVS, but was in a hurry, will try again tomorrow.

- Are you talking about steel wool? You should be able to find that at Wal*Mart or Target. If they don't carry it, I would recommend looking for a kitchen supplies store in a phonebook.

- Q: What are the common surface treatments for galvanized steel coils?

- The common surface treatments for galvanized steel coils include passivation, chromate coating, and oiling. Passivation is a process where a thin layer of protective material, such as zinc phosphate or chromate, is applied onto the galvanized steel surface. This layer helps to enhance the corrosion resistance of the steel by providing a barrier against moisture and atmospheric elements. Passivation also improves the adhesion of subsequent coatings or paints that may be applied to the steel. Chromate coating, also known as chromating or chromate conversion coating, involves the application of a thin layer of chromate onto the galvanized steel surface. This coating provides an additional layer of protection against corrosion and improves the appearance of the steel. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is another common surface treatment for galvanized steel coils. This involves the application of a thin layer of oil onto the surface of the steel, which helps to prevent the formation of rust and corrosion during storage and transportation. Oiling also provides temporary protection against moisture and other environmental factors until the steel is further processed or used in its final application. These surface treatments are commonly used to enhance the performance, durability, and appearance of galvanized steel coils, ensuring that they can withstand harsh conditions and maintain their quality over time.

- Q: What are the different methods of roll forming steel coils?

- There are several different methods of roll forming steel coils, each with its own unique characteristics and applications. Some of the most common methods include: 1. Traditional Roll Forming: This is the most widely used method and involves passing a continuous strip of steel through a series of rollers to gradually shape it into the desired profile. This method provides high precision and repeatability, making it suitable for producing complex shapes and profiles. 2. Pre-Punch and Cut: In this method, the steel strip is pre-punched with holes or slots before it is roll formed. This allows for easier cutting and shaping of the material during the forming process. Pre-punching and cutting can improve efficiency and reduce waste in certain applications. 3. Post-Punch and Cut: This method is similar to pre-punching and cutting, but the holes or slots are added after the roll forming process. This allows for more flexibility in creating custom shapes and designs, as the holes can be placed precisely where needed. 4. Post-Forming: In some cases, the steel strip may be first roll formed into a basic shape or profile and then further manipulated or formed after the initial roll forming process. This method allows for additional customization and can be used to create more complex geometries. 5. Progressive Roll Forming: This method involves passing the steel strip through a series of rollers in a continuous process, with each roller gradually adding a specific feature or forming a particular part of the final profile. Progressive roll forming is commonly used for long, continuous profiles with repetitive shapes. 6. Incremental Roll Forming: In this method, the steel strip is incrementally formed by a series of small movements of the rollers. This allows for greater flexibility in shaping complex profiles and can be particularly useful for producing prototypes or low-volume production runs. Overall, the choice of roll forming method depends on the specific requirements of the application, such as the desired shape, complexity, precision, and production volume. Each method offers its own advantages and limitations, and manufacturers often select the most appropriate method based on these factors.

- Q: How are steel coils used in the production of household appliances?

- Steel coils are used in the production of household appliances as they are a primary material for manufacturing various components like frames, panels, and cabinets. The coils are typically processed and formed into the desired shapes, providing strength, durability, and structural stability to appliances such as refrigerators, washers, dryers, and ovens.

Send your message to us

PPGI Prepainted Galvanized Steel Coil With Different Width 1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords