PPGI Insulated XPS Sandwich Panel - Innovative Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ackaging & Delivery

| Packaging Detail: | Protective film on each panel, panels into standard seaworthy pallet, foam protection, special corner protective material for Insulated XPS Sandwich Panel |

| Delivery Detail: | upon deposit at stock or 7days after deposit for products |

Specifications

Insulated XPS Sandwich Panel

1.Light Weight

2.Impact Resistance

3.Thermal Insulation

4.Corrosion Resistant

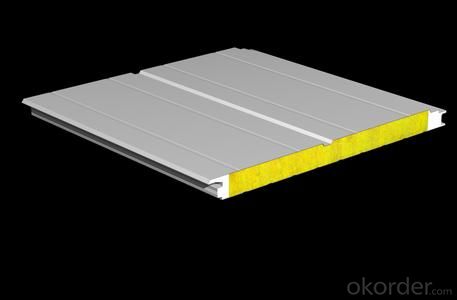

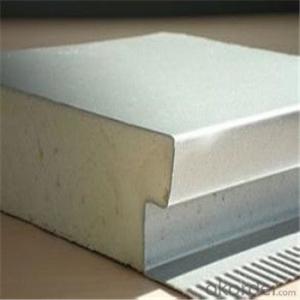

Innovative Building Material Insulated XPS Sandwich Panel

Description:

Fiberglass Reinforced Plastic (FRP) sheet as surface panel at both sides, Polystyrene (XPS also called Extrusion board) as core. They are compounded from high pressure and vacuum, guaranteeing the strength and stability.

The manufacturing process involves the bonding of two outer faces or high gloss FRP flat sheet under pressure to an inner core of insulation material being High density EPS/XPS/PU foam. Using Daison FRP produces sandwich panels with excellent physical attributes including flexible strength, high rigidity, column strength and high impact resistance.

Specification:

Effective width | Wall panel: 950mm 1150mm 1200mm; Roof panel: 950mm 980mm |

Length | According to customer's request |

Materials | Extruded Polystyrene Foam (XPS), fiberglass reinforced plastic (FRP) |

Structure | Upper and lower layer: FRP sheet |

Middle: XPS/EPS/PU foam board | |

Thickness | FRP sheet: 0.8-6mm |

Density of XPS | 30-65kg/m3 |

Color | Ral-scale or customer specific |

Features | Light in weight, heat insulation, water resistant, green and environmental |

Application | Hatchery & incubation equipment, compartments and external walls of building and truck body, cleaning workshops,etc. |

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Foam benzene board capacity of not less than 18kg, other indicators in line with national regulations

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. These panels provide excellent insulation, durability, and aesthetic appeal, making them a practical choice for creating a modern and visually appealing showroom. Additionally, sandwich panels can be customized to meet specific design requirements and offer ease of installation, making them a suitable option for automotive showrooms.

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- First, the electricity management: ⒈ temporary electricity must be "" construction site temporary electricity safety technical specifications "JGJ46-88" compilation of electricity construction organization design and development of safe electricity technical measures and electrical fire protection measures. ⒉ temporary electricity engineering drawings must be drawn solely by the electrical engineering and technical personnel, after the approval of the technical person as a temporary basis for construction. ⒊ temporary electricity construction organization design content and steps: ⑴ site exploration, to determine the power line into the total distribution box (cabinet), the distribution of electrical box location and line direction. ⑵ load calculation, select the wire cross-section and electrical type, specifications. ⑶ draw electrical plan, elevation and wiring system diagram.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- The inner panel can be installed with conventional technology, pay attention to the edge, the installation of corners, as well as their installation with the wallboard order, part of the first to install

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask!

- Q: Color steel sandwich board on the price of how much?

- Surface leveling should be able to, but the words come back, multilayer is cheaper than the former! For more information, better advice, free of charge to provide concrete waterproof water leakage II Cao Hao 丨 sell Zhatai Chunjun repair professional and technical advice, from today's repair, tomorrow leak;

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- . different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. . different insulation properties: the three polyurethane sandwich panels the best. . waterproof performance is different: the three polyurethane and EPS better than rock wool. . the density of different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally . polyurethane is generally 40. In short, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure, Have a number.

- Q: Can sandwich panels be used for ticket booths?

- Ticket booths can indeed utilize sandwich panels. Composed of two slim outer layers and a thermal insulating core material, sandwich panels possess a reputation for their robustness, longevity, and energy efficiency. These characteristics render them an excellent selection for diverse construction purposes, including ticket booths. By offering insulation against extreme temperatures, reducing noise, and providing fire resistance, sandwich panels offer essential attributes for ticket booths. Furthermore, their lightweight nature allows for effortless transportation and installation. They can be tailor-made to accommodate specific design specifications and require minimal maintenance. Consequently, sandwich panels emerge as a fitting and pragmatic choice for ticket booths.

Send your message to us

PPGI Insulated XPS Sandwich Panel - Innovative Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords