Non woven Fabrics for Baby Wipe Raw Material, 30-100gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

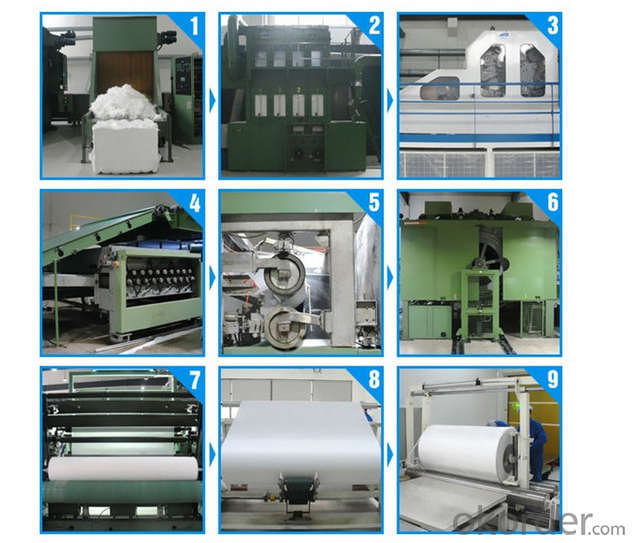

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

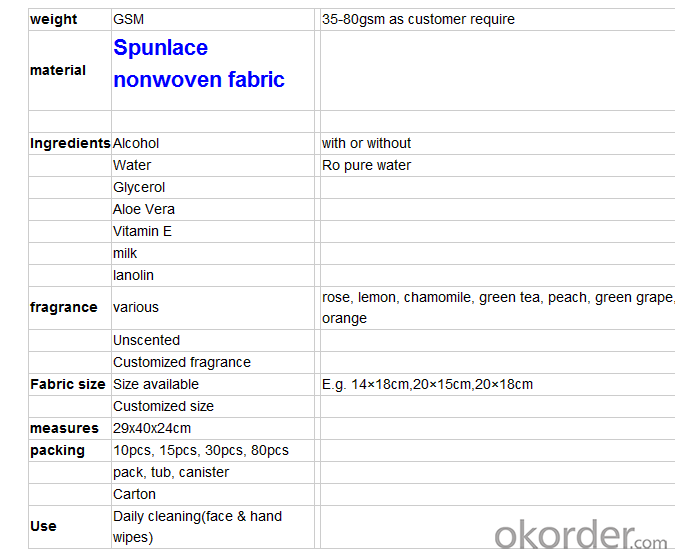

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What are the test tests for the color fastness of textiles?

- 8, perspiration color fastness 9, dry hot color fastness 10, heat pressure color fastness 11, resistance to water fastness 12, color fastness to brush

- Q: What is the textile project

- Graduates of textile engineering can generally work in the technical and business management departments of textile enterprises in the process design, production management, product development and other work, to the business and foreign trade and other departments engaged in business management and professional foreign trade work, but also in scientific research units, Textile schools engaged in scientific research, teaching work.

- Q: What is the anti-perspiration finishing of textiles?

- At the same time, the fabric hydrophilic surface in the hydrophilic, the corresponding waterproof surface can not see the watermark. At present in the knitted fabric on the anti-perspiration finishing more mature, in the weight of the lower woven fabrics, especially light-colored anti-perspiration effect is not particularly ideal

- Q: Differences between textile mills and garment factories

- After the carding, and lines, twisting, roving, spun yarn, winding, warping, weft, weaving, finishing and other long process made of gray cloth, and then sent to the printing and dyeing plant dyeing and finishing,

- Q: What are the types of textiles that are different?

- According to the different production methods are divided into line class, with class, rope, woven fabrics, textile fabrics and other six categories:

- Q: What is a textile fabric?

- Dyeing yarn - weaving - finishing. Characterized by good color fastness. Flower pattern rich. Dyed cloth: no color of the yarn woven into the fabric after the dyeing finishing after finishing the finished product is a cloth. The cost of similar products, the cost of color weaving is lower. But the color fastness worse than the yarn weaving.

- Q: tera textile processing where to learn

- Textile-related materials are available through collection. You can in the big city of the relevant office where the NPC get the drawings and then that textile

- Q: China is now optimistic about which one of the textile industry

- I am undergraduate is a textile engineering, graduate students for the dyeing and finishing, the textile industry more understanding, that the industry with all the future!

- Q: What is the specialty of textile science and engineering?

- The research contents of the textile discipline have changed obviously, and the cross and infiltration of the disciplines such as bioengineering, environmental protection engineering and material science engineering have become more and more close.

- Q: What is the imo standard in the textile industry?

- The purpose of the Global Organic Textiles Standard is to ensure that textile fabrics and garments of textiles manufacturers are certified and recognized in all major world markets as an important step towards harmonization and transparency of textile marks.

Send your message to us

Non woven Fabrics for Baby Wipe Raw Material, 30-100gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords