COLOR TARPAULIN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging Detail: | grade one materials pe tarpaulin: each piece pack into PP bag with lable, outside packing as client request |

Specifications

grade one materials pe tarpaulin:

1) High tensile,high quality

2) customizalbe pe tarpaulin

3) rope and grommet reinforced

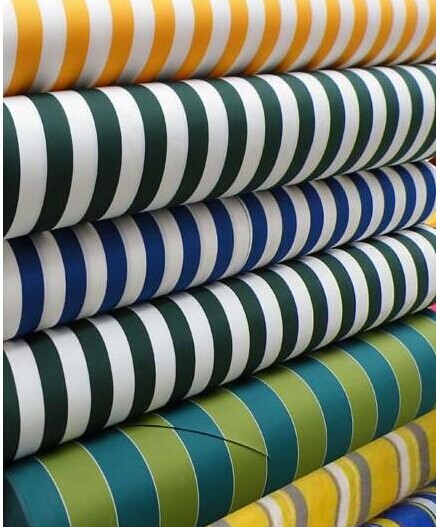

PE tarpaulin/ poly tarp/ polyethylene tarpaulin /pe sheet/pe canvas/pe tarp Material 1)100% polyethylene . Both Sides LDPE (low density polyethylene) Laminated Weight: 50-300G/SQM Yarn Count 500D-1500D Weave 6*6-16*16 Width 2m,4m,6m,etc Length 100, 200,no limit Thickness 55-300 micron(0.1mm-0.3mm) Shape customizable shape Color:1)blue,green,grey,sliver,yellow,red,brown,orange,white,black, camouflage,transparent or as order Size: 1) 2x3m, 3x4m,3x5m, 4x5m, 4x6m, 5x8m, 6x8m, 6x10m, any size available |

- Q: What is the meaning of TOP in the textile industry?

- Polar fleece is generally the case, towel cloth fabric - dyeing - grasping hair - pull hair - cut hair - shake tablets - stereotypes ordinary double-sided cloth are generally stained + stereotypes, double-sided type too much.

- Q: Textile raw materials of mineral fiber

- A natural or synthetic polymer compounds as raw materials by chemical spinning made of fiber. Can be divided into man-made fibers, synthetic fibers, inorganic fibers

- Q: Differences between textile mills and garment factories

- Hello, textile mills, including from the cotton into yarn, from the yarn woven into a fabric, while the printing and dyeing factory to fabric into fabric

- Q: Are hats a class of textile and apparel products?

- All year round seems to generally only winter hat, hat should belong to the textile and apparel products bar. Jewelery is available all year round.

- Q: Antistatic fabrics of textile electrostatic materials

- Clothing charged, a large number of adsorption of dust, easy to contaminate, and clothing and the human body, clothing and clothing will occur entanglement phenomenon or produce spark. Therefore, the electrostatic interference, affecting the smooth progress of processing, affecting the quality of the product and the performance of the fabric, etc.

- Q: Performance requirements for textile fibers

- Fiber wear resistance. Fibers and their products in the processing and the actual use of the process, due to continue to withstand friction caused by wear and tear. Fiber wear resistance refers to the fiber resistance to external wear performance

- Q: The difference between double distribution and processing in textile fabrics

- Distribution - that is, you buy fabrics, only the money on the line, all of them will give you a good job.

- Q: The Factors Affecting the Capillary Effect of Textile Garment

- The higher the effect, the better the impact of post-processing quality, such as leveling, dyeing rate, fastness and so on.

- Q: What is the earliest textile raw material?

- The ancient Roman Empire was first through the "Silk Road" on the spread of silk, said China as "silk country"

- Q: Why is cotton textiles shrinking?

- In the immersion of water, the water will make the fiber molecules between the contact gradually weakened, the fiber surface friction decreased, so that the temporary "stable" state is destroyed, the fiber will be restored or close to the original balance

Send your message to us

COLOR TARPAULIN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords